VIRTA-Yoke: A Virtual-Integrated Poka-Yoke System for Error

Prevention and Operator Training in Manufacturing Processes

Guillermo Leale

1,2 a

, Baltazar Cortina

1

and Rodrigo D’Andrea

1

1

Radium Rocket, Rosario, Argentina

2

Universidad Tecnol

´

ogica Nacional Facultad Regional Rosario,

Departamento Ingenier

´

ıa en Sistemas de Informaci

´

on, Argentina

Keywords:

Poka-Yoke, Virtual Reality, Error Prevention, Operator Training.

Abstract:

This paper introduces VIRTA-Yoke (VIRTA: Virtual Integrated Reliability and Training Assistant), a proof-of-

concept virtual Poka-Yoke platform developed to increase reliability and efficiency in manufacturing processes

for aluminum engine components. In contrast to traditional mechanical Poka-Yoke systems that require cus-

tom fixtures for each part, VIRTA-Yoke employs a low-cost webcam and a virtual reality (VR) headset to guide

operators through each assembly step, verify correct placement in specific control areas, and provide real-time

feedback when deviations occur. The system uses a convolutional neural network (ConvNet) to detect errors

in coil insert placements. This information appears on the VR headset, minimizing operator distraction, op-

timizing operation times, and improving process adherence. In addition, the VR headset serves as a training

environment, allowing new personnel to learn assembly procedures through a virtual component model be-

fore working on the factory facility. Preliminary tests indicate an accuracy exceeding 90% in overall defect

detection, suggesting that VIRTA-Yoke is a scalable, cost-effective method for streamlining quality control,

improving operator training, and eliminating the need for multiple custom mechanical fixtures across a wide

range of parts.

1 INTRODUCTION

Poka-Yoke, a term coined by Shigeo Shingo in the

1960s, represents a fundamental concept in the Toy-

ota Production System aimed at preventing and de-

tecting human errors before they manifest as defects

(Shingo, 2021; Martinelli et al., 2021; Martinelli

et al., 2022). Initially, Poka-Yoke solutions were sim-

ple mechanical devices—such as guides, pins, or limit

switches—designed to halt the progression of defec-

tive products through the manufacturing line. Over

time, these measures have evolved well beyond their

original scope, demonstrating effectiveness in cor-

recting errors, as well as anticipating and preemp-

tively eliminating potential process failures (Prabowo

and Aisyah, 2020; Hetma

´

nczyk and Michalski, 2013;

Vinod et al., 2015).

This orientation aligns closely with lean manu-

facturing principles, which aim to minimize waste,

streamline processes, and continuously improve qual-

ity (Hines and Rich, 1997; Bicheno and Holweg,

2008; Liker, 2004; Mor et al., 2019; Lek

ˇ

si

´

c et al.,

a

https://orcid.org/0000-0003-3983-1496

2020). By removing conditions that lead to errors,

Poka-Yoke fosters a culture of ongoing improvement

and increased reliability in production environments

(Alves et al., 2012; Prabowo and Aisyah, 2020;

Lek

ˇ

si

´

c et al., 2020; Jiang et al., 2014). Shingo (Shi-

geo and Dillon, 1989) distinguishes between control

type mechanisms, which halt the process at the detec-

tion of an error, and warning type mechanisms, which

alert operators so that they may take corrective actions

without stopping production entirely.

As manufacturing adopts more digital approaches,

the concept of Poka-Yoke has expanded to virtual

implementations. Instead of requiring mechanical

changes to production lines, virtual Poka-Yoke sys-

tems rely on digital tools —such as computer vision,

machine learning, and virtual and/or augmented real-

ity— to identify anomalies and guide operators (Mar-

tinelli et al., 2021; Prabowo and Aisyah, 2020; Lek

ˇ

si

´

c

et al., 2020; Soares Alcal

´

a, 2020; Kim et al., 2018;

Saleem et al., 2020). These methods facilitate rapid

adjustments to inspection criteria and reduce the need

for extensive redesigns when products or specifica-

tions change.

Leale, G., Cortina, B. and D’Andrea, R.

VIRTA-Yoke: A Virtual-Integrated Poka-Yoke System for Error Prevention and Operator Training in Manufacturing Processes.

DOI: 10.5220/0013381100003912

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 20th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2025) - Volume 1: GRAPP, HUCAPP

and IVAPP, pages 421-428

ISBN: 978-989-758-728-3; ISSN: 2184-4321

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

421

Studies have shown that applying convolutional

neural networks (ConvNets) and advanced image pro-

cessing can deliver high accuracy in defect detec-

tion (Huang and Kovacevic, 2011; El-Agamy et al.,

2016; Kim et al., 2018; Saleem et al., 2020). Such

approaches, along with VR- and/or AR-based train-

ing scenarios, allow operators to interact with vir-

tual models of parts, practice identifying potential

defects, and refine their inspection methods before

working with actual components (Hedelind and Jack-

son, 2011; Jiang et al., 2014; Li et al., 2020; Siri-

borvornratanakul, 2016). This capability reduces re-

liance on costly physical resources and live produc-

tion downtime, while operators gain familiarity with

the process in a flexible, adaptable environment.

In essence, the evolution of Poka-Yoke —across

mechanical, virtual, and VR- and/or AR-integrated

solutions— reflects a broader trend in manufacturing

toward greater flexibility, adaptability, time efficiency,

and intelligence in quality assurance. Through contin-

uous refinement and integration with advanced digital

technologies, Poka-Yoke remains a key strategy for

error prevention, contributing to more efficient and re-

liable production systems in an increasingly dynamic

industrial landscape.

Based upon these concepts, this work presents

VIRTA-Yoke, a Virtual Integrated Reliability and

Training Assistant, which is a proof-of-concept sys-

tem under development. This effort is positioned

within a real industrial context, namely an aluminum

parts foundry supplying the automotive sector. The

primary challenge faced by the foundry involves a

set of production steps where some mechanical Poka-

Yoke devices have already been implemented, while

other stages remain susceptible to human errors. Such

errors impose significant costs, time delays, and oper-

ational inefficiencies, creating the need for additional,

cost-effective strategies to mitigate quality issues.

To address these concerns, VIRTA-Yoke is pre-

sented as a system composed of two integrated lay-

ers, complemented by a dedicated training module for

employees. The core solution is based on a standard

webcam capturing images of specific sections of each

manufactured part. These images are analyzed by a

state-of-the-art computer vision algorithm that pro-

vides a probabilistic assessment indicating whether

the processed part is correct or defective. The result-

ing information is displayed on a monitor, guiding the

operator through repetitive verification tasks and im-

proving overall decision-making accuracy. This vir-

tual Poka-Yoke design aims to reduce hardware com-

plexity and avoid substantial modifications to the pro-

duction line.

In parallel, a virtual reality (VR) headset, adapted

to provide augmented reality (AR) guidance

1

, supple-

ments the visual assistance by presenting the analy-

sis results directly to the operator, in a manner such

that no step is overlooked. This AR layer displays

error outputs in a user-friendly manner and leads the

employee through the entire process, preventing the

skipping of critical tasks, as well as reducing the time

needed to check each step, which is currently fol-

lowed on a printed sign mounted on the wall. Ad-

ditionally, the VR headset is employed off-site as a

training tool, relying on a three-dimensional model of

the workpiece to familiarize new employees with pro-

duction procedures before they begin on-site work.

By integrating image-based inspection, AR-guided

verification, and pre-emptive training, this proof-of-

concept system supports operational robustness, re-

duces human error, and provides a more reliable and

cost-effective manufacturing environment.

2 VIRTA-Yoke AS A

PROOF-OF-CONCEPT SYSTEM

VIRTA-Yoke is conceived as a proof-of-concept sys-

tem that is introduced within the manufacturing pro-

cess of an aluminum component destined for engine

assembly. Its aim is to detect and prevent errors in

specific physical sections of the workpiece, referred

to here as control areas. These control areas are lo-

cated on one face of the part and consist of a num-

ber of holes with two different sizes and two different

depths into which coil inserts (called helicoil in this

paper

2

) must be placed. A reference image for the he-

licoil is shown in Figure 1. A representative image

of a control area is provided in Figure 2, although the

complete geometry of the part cannot be displayed for

confidentiality reasons. Nevertheless, this example of

a control area illustrates the general principle, since

similar control areas can be identified and examined

across different workpieces.

An example of a placement error for the helicoil

is shown in Figure 3, where the helicoil exhibits in-

correct depth. Specifically, the tip of the helicoil pro-

1

For clarity, the device is commonly known as a VR

headset. However, we use its AR capabilities in this work.

Therefore, we will use the expression VR headset when re-

ferring to the device itself, and the term AR when describing

its application and functionality.

2

In this study, the term helicoil will be used to refer to

coil inserts. Although coil insert is the generic technical

designation, the term helicoil corresponds to the commer-

cial name commonly used by factory personnel and will be

adopted throughout this paper for consistency with the ter-

minology employed in the production environment.

GRAPP 2025 - 20th International Conference on Computer Graphics Theory and Applications

422

trudes beyond the hole where it should be fully in-

serted. This is one of the multiple types of errors that

can be found during the process

3

. For reference, a

correctly placed helicoil can be seen in Figure 2.

Figure 1: Reference image for a helicoil.

Figure 2: Example of a control area with a helicoil insert

correctly placed.

Figure 3: Example of a control area with a helicoil insert

placed incorrectly (incorrect depth: too high).

3

Other errors include: no helicoil inserted; the tip of the

helicoil (the section of metal that extends beyond the spiral

structure) is not properly cut; helicoil too deep; helicoil too

high.

It is important to note that VIRTA-Yoke does not

aim to identify manufacturing defects on the alu-

minum part itself, such as dents, excess material, or

dimensional deviations. Our system rather focuses on

the verification of these specific operations involving

control areas. By detecting errors in these controlled

steps, the proposed VIRTA-Yoke system addresses a

significant source of defects that currently arise in the

production line.

The expectation for this proof-of-concept is that

it can effectively address the majority of these insert-

related and similar errors found in the facility. The

intended approach would cover hundreds of pieces

with a cost far lower than that associated with tra-

ditional mechanical Poka-Yoke devices, which must

be custom-built for each individual part. Through

the integration of a single webcam and a VR head-

set, the system leverages widely available and reason-

ably priced components, increasing its scalability and

adaptability to a broad range of production scenarios.

3 THE PROCESS INVOLVING

VIRTA-Yoke

3.1 The VR Headset Guidance

The first part of the proposed solution involves using

the VR headset as a step-by-step guidance tool within

the assembly process. Currently, operators follow a

series of instructions displayed on a board at their

workstation. The first step in the process requires

placing helicoil inserts into designated holes in the

aluminum part. The placement and the tools required

for this task are described in printed signs mounted

on the wall within the operator workstation. In ad-

dition, the order in which each insert must be placed

is indicated on a custom-made plate that immobilizes

the part, serving as a basic mechanical Poka-Yoke for

this initial step. However, this plate must be manu-

factured to the exact specifications of the particular

piece, a considerable drawback given the hundreds of

different part types handled by the facility.

In contrast, the proposed method utilizes the VR

headset to provide a dynamic and adjustable step-by-

step guide. By wearing the headset, the operator re-

ceives clear, real-time instructions for each action to

be performed. After completing each step, the opera-

tor sends a signal (e.g., using a controller or a simple

input device, or even their own hand, recognizable by

the device) to the headset, confirming that the task has

been done. The headset then displays the next step.

This approach addresses two frequent issues, namely

operators occasionally skipping steps due to fatigue

VIRTA-Yoke: A Virtual-Integrated Poka-Yoke System for Error Prevention and Operator Training in Manufacturing Processes

423

or distraction, and the additional delay caused by the

movements that the operators have to make to check

or review the following steps, provided that the cor-

rect sequence is always visible in a highly accessible

manner. The AR-based guide can be easily adapted to

new parts or modified procedures through software,

thus eliminating the need to produce custom-made

physical guides for each piece type. This represents a

significant cost reduction and flexibility improvement

compared to conventional mechanical Poka-Yoke so-

lutions.

As an example of the process as well as the pro-

vided guidance, the operation guide for working with

one of the components used in this research is pro-

vided in the supplementary material

4

, including in-

formation up to the extent allowed by confidentiality

constraints.

3.2 The Low-Cost Webcam

The next component of the system employs a ma-

chine learning-based approach, using a standard state-

of-the-art algorithm in combination with a low-cost

webcam. The device chosen for our proof-of-concept

system is a Logitech C922 Pro HD Stream Webcam

(1080p, 30FPS). By placing the workpiece in a fixed

position, the camera captures images of the desig-

nated control areas and provides a high-confidence

assessment of their status, indicating whether the he-

licoil insert has been correctly placed and whether the

tip has been properly cut. Through this example, it

becomes clear that control areas adhere to one defined

correct shape and can exhibit multiple error types, all

of which the algorithm is designed to detect.

The verification results are displayed on the VR

headset, allowing operators to access critical quality

checks without shifting their gaze or consulting sepa-

rate monitors. This integrated feedback mechanism

is currently the most practical solution to the chal-

lenge of efficiently verifying control areas, minimiz-

ing operator distractions, and reducing overall opera-

tion times.

A notable limitation at present (December 2024)

is the inability to use the chosen VR headset, namely

Meta Oculus Quest 3, to provide direct image input

for the algorithm analysis

5

. Although the Quest 3 was

selected for its availability and cost-effectiveness, the

manufacturer currently restricts external video output

from its camera feed. As a result, the webcam remains

4

Supplementary Material is available at https://tinyurl.

com/virta-yoke

5

For further information, see

https://www.meta.com/blog/quest/

new-safety-privacy-features-mr-headset-family-friendly/

necessary to capture images, with the processed infor-

mation subsequently transmitted to the AR environ-

ment. Within the AR interface, the system displays

the number of correctly processed control areas com-

pared to the total number required. If not all areas

meet the specified criteria, the guidance system halts

progress until the error is corrected. Once the issue is

resolved, a signal is sent to the VR headset, enabling

the operator to proceed to the next task.

In addition to providing immediate feedback to

operators, the system generates notifications for su-

pervisors, capturing a wide range of real-time infor-

mation in detailed text-based records. These records

will evolve in the next system version, scheduled for

March 2025, into comprehensive back-office dash-

boards accessible to both mid-level and senior man-

agement. These dashboards will aggregate detailed

logs of operator interactions, error detections, cor-

rective actions, and real-time process metrics. Data

will include start and end times for each process,

the sequence and duration of steps guided by the

VR headset, any downtime or delays encountered,

and gaze-based attention estimates derived from eye-

tracking metrics. The collected metrics will also log

errors identified by the algorithm and warning mes-

sages prompted when mandatory steps are missing.

This enhanced data environment aims to support ad-

vanced data-driven decision-making, enabling contin-

uous improvement, better resource allocation, and im-

proved quality management throughout the produc-

tion workflow.

3.3 The Computer Vision Algorithm

This section focuses on the algorithm itself. The pre-

sented results emerge from the integration of a state-

of-the-art convolutional neural network (CNN) archi-

tecture based on Conv2D and MaxPooling2D lay-

ers implemented using the TensorFlow/Keras frame-

work. Preliminary tests conducted on a representative

dataset with real images from correct and incorrect

pieces indicate that the model achieves an accuracy

exceeding 90% in overall defect detection. The Con-

vNet model, once trained and validated, is integrated

into a dedicated software application installed on a

workstation computer. The complete code is available

in https://pastebin.com/9Yb05hrn.

The algorithm was developed following a struc-

tured methodology. The convolutional neural net-

work (ConvNet) employed in this study consists of

an architecture combining three Conv2D layers with

ReLU activation functions and MaxPooling2D lay-

ers for feature extraction, followed by two fully con-

nected layers to perform classification. The Conv2D

GRAPP 2025 - 20th International Conference on Computer Graphics Theory and Applications

424

layers include 32 filters in the first layer and 64 fil-

ters in the second and third layers, all with a filter

size of (3, 3). The fully connected layers comprise

64 units with ReLU activation and a final softmax

layer with 2 units to compute class probabilities. The

model was trained using the Adam optimizer with an

initial learning rate of 0.001 and sparse categorical

crossentropy loss, over 15 epochs with a batch size of

1. Images were preprocessed by standardizing them

to a resolution of 32x32 pixels and normalizing pixel

values to the range [0,1]. Data augmentation, includ-

ing random rotations and zoom, was applied to the

training dataset to improve robustness. The training

process was conducted on a MacBook Pro (M1, 8GB

RAM), and required approximately 1 minute of pro-

cessing time. The resolution of 32x32 pixels was se-

lected to balance computational efficiency and model

accuracy, as it is sufficient to capture the types of de-

fects analyzed. While the dataset size (60 images)

may limit generalization capabilities, this limitation

was partially mitigated through data augmentation.

In future iterations, we aim to expand the dataset to

further enhance the robustness and accuracy of the

model.

As indicated above, a set of 60 labeled images

from 30 correct areas and 30 incorrect control areas

was organized into training, validation, and testing

subsets (80%/20% proportion between training and

test, following standard machine learning practices),

each containing examples of correct control areas and

incorrect control areas in two defect categories. The

webcam was placed in a fixed position, 20 centime-

ters above the workpiece, under white non-directional

artificial light.

Following training, performance was evaluated

using the validation and test datasets, reporting ac-

curacy as a primary metric, as well as the standard

precision, recall and F1-score metrics. Output results

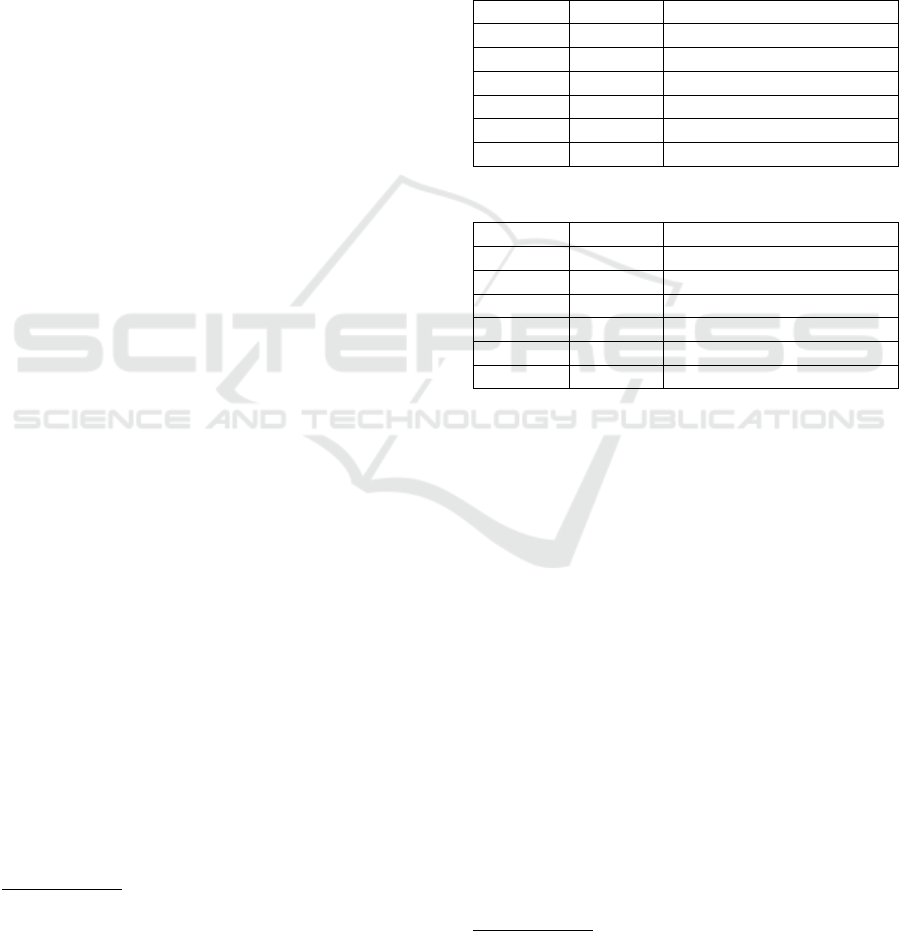

for these metrics can be seen in Table 1. Visualization

functions were created to display predictions on sam-

ple images, allowing qualitative inspection of model

behavior and detection of misclassifications. Finally,

the approach validated the feasibility and accuracy of

the computer vision-based quality control system.

Table 1: Output metrics for the algorithm.

Metric Value

Accuracy 0.92

Precision 0.92

Recall 0.93

F1-Score 0.92

3.4 Training and Operator Instruction

with VIRTA-Yoke

The training component of VIRTA-Yoke leverages a

virtual environment that allows operators to become

thoroughly familiar with the production part and its

associated control areas before entering the actual fac-

tory facility. By employing a VR headset, the opera-

tor can manipulate a three-dimensional model of the

component, inspecting it from all angles and identi-

fying the operations required at each step. For this

proof-of-concept, the control areas where helicoil in-

serts must be placed can be visually examined and

virtually “marked” as inspected once the operator has

verified their correct configuration. This immersive

training environment reduces the reliance on real-

world machine time and physical workpieces, effec-

tively lowering training costs and minimizing disrup-

tions to ongoing production.

In practice, this virtual training scenario enables

off-site learning, allowing operators to become profi-

cient in identifying correct and incorrect configura-

tions without consuming factory resources. Rather

than dedicating valuable time and materials to train

personnel directly on the production line, the system

provides a versatile and cost-effective solution. Oper-

ators can interact with a three-dimensional mock-up

that mirrors the dimensions and complexity of the ac-

tual part. This virtual representation allows operators

to gain confidence and agility in handling the compo-

nent, mastering inspection techniques that will later

be applied to genuine parts.

The training functionality of VIRTA-Yoke is fur-

ther complemented by the inclusion of three de-

mostration videos showcasing the proof-of-concept

training module. These videos feature a dummy

piece, which is designed to replicate the dimensions

and operations of the actual component used in pro-

duction. The dummy part contains several holes,

within which the correct pladement of the helicoil in-

sert must be verified. These holes are prominently

marked in red, indicating the control areas that require

inspection to assess whether the helicoid has been cor-

rectly inserted.

For training purposes, operators use the VR head-

set to manipulate the dummy part in a 360-degree

mixed environment. One hand holds the piece, en-

abling it to be rotated and inspected from all angles,

while the other hand is employed to point to the con-

trol areas and mark them as ”correct” or leave them

unmarked if deemed incorrect. This step-by-step in-

teraction reinforces awareness of the inspection pro-

cess and the motor skills required to perform thorough

inspections.

VIRTA-Yoke: A Virtual-Integrated Poka-Yoke System for Error Prevention and Operator Training in Manufacturing Processes

425

The three training videos provided cover distinct

environments to replicate various production condi-

tions: a) White artificial lighting: this video demon-

strates the inspection process under controlled, op-

timal lighting conditions; b) Printed polygon over-

lays: this video introduces polygonal overlays to sim-

ulate a higher level of detail during the inspection; c)

Dim lighting: this final video reproduces the typical

lighting conditions found in real production facilities,

where operators encounter lower visibility

6

.

By using this pointer to signal that a particular

control area has been inspected, the operator can sim-

ulate the exact steps of the verification process. Upon

confirming the inspection via simple gestural inputs,

the system registers that the control area has been

checked, reinforcing the correct procedure and serv-

ing as an aid to improve muscle memory. This ap-

proach enhances the user’s familiarity with the work-

piece and reduces the learning curve associated with

the real-world implementation of the VIRTA-Yoke

system.

4 EXPERIMENT AND

PRELIMINARY RESULTS

To assess the effectiveness of the VIRTA-Yoke sys-

tem on operational efficiency, an experiment was

conducted involving six volunteer operators selected

across the company’s three shifts (morning, after-

noon, and night, two operators per shift) that collec-

tively cover the full 24-hour production cycle. The

tasks performed for the experiment included work-

ing with multiple control areas with varying hole

sizes and depths, requiring the insertion of helicoil

inserts, following the exact steps necessary to work

on a specific workpiece within the manufacturing pro-

cess. The step-by-step guide for the process used in

the experiment is provided in the supplementary ma-

terial

7

. The primary types of error targeted in this ex-

periment were the incorrect insertion of helicoil in-

serts —specifically those with improper depth—, and

the lack of insertion of helicoil inserts.

Completion times for each operator were

recorded. These measurements were taken under two

conditions: the traditional work setup and a scenario

incorporating the VIRTA-Yoke system. In the first

scenario, the operators performed the tasks following

their standard procedures, without any additional

6

All three videos are available in

https://tinyurl.com/virta-yoke

7

Supplementary Material is available at https://tinyurl.

com/virta-yoke

guidance. The recorded times for each employee

are presented in Table 2. Subsequently, the same

operators were equipped with the VR headset and

provided with dummy parts, which approximate the

size, shape, and complexity of the actual components.

Using the guidance interface provided by VIRTA-

Yoke, including step-by-step instructions delivered

through the VR headset, the operators repeated the

procedures. The times recorded under these enhanced

conditions are listed in Table 3.

Table 2: Scenario 1. Normal conditions. First 5 rows.

Operator Shift Operation Time (Seconds)

O1 Morning 79.26

O1 Morning 93.97

O1 Morning 88.83

O1 Morning 76.08

O1 Morning 82.80

. . . . . . . . .

Table 3: Scenario 2. Using VIRTA-Yoke. First 5 rows.

Operator Shift Operation Time (Seconds)

O1 Morning 75.52

O1 Morning 73.85

O1 Morning 62.95

O1 Morning 70.87

O1 Morning 69.04

. . . . . . . . .

A total of 30 data points were gathered for both

conditions, comprising 5 observations for each op-

erator. A two-way t-test was conducted to compare

the mean completion times. With a 95% confidence

level (p-value = 1.33 × 10

−14

), the analysis indicated

a statistically significant reduction in completion time

when VIRTA-Yoke was employed. Although dummy

parts were used for the VIRTA-Yoke condition and

genuine parts for the traditional scenario, the pieces

were comparable in dimensions and required oper-

ations. Additionally, the experiment was performed

under a failure-free environment to avoid generating

real defects, which could impact actual production.

Following discussions with the production supervisor,

it was agreed that these results provide a valid esti-

mate of the potential time savings achievable through

VIRTA-Yoke. The complete tables for both scenarios

are provided as supplementary material

8

.

8

Supplementary Material is available at https://tinyurl.

com/virta-yoke

GRAPP 2025 - 20th International Conference on Computer Graphics Theory and Applications

426

5 CONCLUSIONS AND FUTURE

WORK

This work has presented VIRTA-Yoke, a proof-

of-concept system integrating virtual Poka-Yoke

methodologies, machine learning-based error detec-

tion, and AR-assisted operator training. The pro-

posed solution aims to enhance reliability, reduce

costs, and streamline the handling of control areas in

the manufacturing of aluminum parts for engine com-

ponents. By combining low-cost hardware (a web-

cam and a commercially available VR headset) with

a state-of-the-art computer vision algorithm, VIRTA-

Yoke guides operators through each step of a complex

process, provides accurate feedback on insert place-

ment, and allows off-site training that does not depend

on physical resources or live production runs.

Preliminary tests have demonstrated encouraging

results, indicating an accuracy exceeding 90% in

overall defect detection in control areas. Operators

can interact with a virtual model of the piece, famil-

iarize themselves with the process, and practice iden-

tifying and verifying control areas. This approach

reduces the risk of skipped steps or overlooked de-

fects, thereby enhancing overall process quality and

operational efficiency. The proposed system also

plans to integrate extensive logging capabilities, ul-

timately enabling supervisors and managers to review

detailed performance data via dashboards and make

data-driven decisions to improve the quality control

process.

While the VIRTA-Yoke system introduces a vir-

tual Poka-Yoke approach, a direct quantitative com-

parison with traditional Poka-Yoke systems is not en-

tirely feasible due to the current manufacturing pro-

cess already utilizing basic mechanical Poka-Yoke

mechanisms for individual steps. The proposed sys-

tem integrates a virtual Poka-Yoke guide for the en-

tire assembly process, serving as a proof of concept

that can be generalized to other components. Tra-

ditional Poka-Yoke systems require custom-built fix-

tures for each specific part, leading to higher costs,

whereas VIRTA-Yoke leverages low-cost webcams

and reusable software, making it more cost-effective.

Although error detection accuracy cannot be directly

compared due to the absence of a controlled produc-

tion environment with deliberate errors, the VIRTA-

Yoke system demonstrates over 90% accuracy in

overall defect detection based on machine learning

metrics. Operator training times are expected to

be similar to traditional systems; however, the VR-

based training module allows training in a flexible

virtual environment without consuming physical re-

sources. Additionally, the scalability of VIRTA-Yoke

far exceeds that of traditional systems, as it can be

adapted to multiple parts by reconfiguring the soft-

ware, whereas mechanical systems require custom

fixtures for each component. These advantages sug-

gest that VIRTA-Yoke offers a cost-effective, scal-

able, and flexible alternative to traditional approaches,

despite the lack of direct performance comparisons.

However, several challenges remain. At present,

the VR headset hardware restricts certain data chan-

nels, preventing a direct input feed of camera images

into the headset, thus needing an external webcam for

capturing real-time data. Future development efforts

will focus on overcoming such limitations. The even-

tual inclusion of logging and dashboard functionali-

ties is scheduled for March 2025, supporting continu-

ous improvement and higher-level oversight.

Additionally, it is worth briefly discussing

whether the use of VR headsets posed challenges for

operators, particularly those with no prior experience

using such technology. While no significant usabil-

ity issues were reported during the initial tests, it is

recommended that future studies incorporate usabil-

ity surveys to assess specific metrics, such as comfort

levels, ease of adaptation to the VR headset, and any

potential impacts on performance or fatigue. These

insights will help refine the system to make it both

effective and user-friendly. However, certain limita-

tions of the implementation must also be acknowl-

edged. One key constraint is the dependence on light-

ing conditions, as variations in illumination can sig-

nificantly impact the final accuracy for the model,

making consistent and controlled lighting essential

for reliable defect detection. Furthermore, the use of

VR headsets may lead to visual fatigue or discomfort

due to prolonged usage, as well as physical fatigue

from the weight of the device. Another technolog-

ical limitation is the battery life of most VR head-

sets, which typically lasts between two to three hours,

which is substantially less than the duration of an op-

erator shift. To address these challenges, the team

has preliminarily discussed alternative VR solutions,

such as X-REAL headsets, which offer improved er-

gonomics and do not rely on battery power. This al-

ternative is under consideration for future iterations

to enhance usability and reduce operator discomfort,

while remaining practical and efficient in real-world

applications.

ACKNOWLEDGEMENTS

The authors would like to express their gratitude to

David Curras, Gonzalo Asencio, Juli

´

an Vicente, Igna-

cio Aristo, and Samuel Trillo for their valuable con-

VIRTA-Yoke: A Virtual-Integrated Poka-Yoke System for Error Prevention and Operator Training in Manufacturing Processes

427

tributions to the development of this work. Special

thanks are extended to Radium Rocket for their sup-

port and collaboration, as well as to the factory that

generously allowed us to observe their processes and

experiment with real components. The authors also

acknowledge the Department of Information Systems

Engineering at UTN-FRRO for their continuous assis-

tance and resources that made this research possible.

REFERENCES

Alves, A. C., Dinis-Carvalho, J., and Sousa, R. M. (2012).

Lean production as promoter of thinkers to achieve

companies’ agility. The Learning Organization,

19(3):219–237.

Bicheno, J. and Holweg, M. (2008). The Lean toolbox: The

essential guide to Lean transformation. Picsie Books.

El-Agamy, M., Awad, M., and Sonbol, H. (2016). Auto-

mated inspection of surface defects using machine vi-

sion. The International Conference on Applied Me-

chanics and Mechanical Engineering.

Hedelind, M. and Jackson, M. (2011). How to improve the

use of industrial robots in lean manufacturing systems.

Journal of Manufacturing Technology Management.

Hetma

´

nczyk, M. and Michalski, P. (2013). The aid of a

mistake proofing with the use of mechatronic systems

according to the poka-yoke methodology. Advanced

Materials Research.

Hines, P. and Rich, N. (1997). The seven value stream map-

ping tools. International journal of operations & pro-

duction management, 17(1):46–64.

Huang, W. and Kovacevic, R. (2011). A laser-based vision

system for weld quality inspection. Sensors.

Jiang, Y.-M., Lee, H.-H., Lien, C.-C., Tai, C.-F., Chu, P.-C.,

and Yang, T. (2014). 3d vision-based dietary inspec-

tion for the central kitchen automation.

Kim, H.-J., Ahn, E., Shin, M., and Sim, S. (2018). Crack

and noncrack classification from concrete surface im-

ages using machine learning. Structural Health Mon-

itoring.

Lek

ˇ

si

´

c, I.,

ˇ

Stefani

´

c, N., and Ve

ˇ

za, I. (2020). The impact of

using different lean manufacturing tools on waste re-

duction. Advances in Production Engineering & Man-

agement.

Li, D., Liu, C., Chen, C., and Zhao, Z. (2020). Semantic

segmentation of a printed circuit board for component

recognition based on depth images. Sensors.

Liker, J. K. (2004). The Toyota Way: 14 Management

Principles from the World’s Greatest Manufacturer

McGraw-Hill Education.

Martinelli, M., Gamberini, R., and Lippi, M. (2021). Poka

yoke meets deep learning: A proof of concept for an

assembly line application.

Martinelli, M., Lippi, M., and Gamberini, R. (2022). Poka

yoke meets deep learning: A proof of concept for an

assembly line application. Applied Sciences.

Mor, R. S., Bhardwaj, A., Singh, S., and Sachdeva, A.

(2019). Productivity gains through standardization-of-

work in a manufacturing company. Journal of Manu-

facturing Technology Management.

Prabowo, R. F. and Aisyah, S. (2020). Poka-yoke method

implementation in industries: A systematic literature

review. Ijiem - Indonesian Journal of Industrial Engi-

neering and Management.

Saleem, M. R., Park, J. W., Lee, J.-H., Jung, H., and Sar-

war, M. Z. (2020). Instant bridge visual inspection

using an unmanned aerial vehicle by image capturing

and geo-tagging system and deep convolutional neural

network. Structural Health Monitoring.

Shigeo, S. and Dillon, A. (1989). A study of the toyota pro-

duction system from an industrial engineering view-

point. Estados Unidos.

Shingo, S. (2021). Zero quality control: Source inspection

and the poka-yoke system. Routledge.

Siriborvornratanakul, T. (2016). A study of virtual reality

headsets and physiological extension possibilities. In

Computational Science and Its Applications–ICCSA

2016: 16th International Conference, Beijing, China,

July 4-7, 2016, Proceedings, Part II 16, pages 497–

508. Springer.

Soares Alcal

´

a, S. G. (2020). Object defect detection based

on a vision system with a microcontroller and an arti-

ficial neural network. Itegam- Journal of Engineering

and Technology for Industrial Applications (Itegam-

Jetia).

Vinod, M., Devadasan, S., Sunil, D., and Thilak, V. (2015).

Six sigma through poka-yoke: A navigation through

literature arena. The International Journal of Ad-

vanced Manufacturing Technology.

GRAPP 2025 - 20th International Conference on Computer Graphics Theory and Applications

428