A Modular Framework for Knowledge-Based Servoing: Plugging

Symbolic Theories into Robotic Controllers

Malte Huerkamp

1,∗ a

, Kaviya Dhanabalachandran

1,∗ b

, Mihai Pomarlan

2 c

, Simon Stelter

1 d

and

Michael Beetz

1 e

1

Institute for Artificial Intelligence, University of Bremen, Germany

2

Applied Linguistics Department, University of Bremen, Germany

{huerkamp, kaviya, pomarlan, stelter, mbeetz}@uni-bremen.de

Keywords:

Symbolic Reasoning, Motion Control, Robotic Manipulation.

Abstract:

This paper introduces a novel control framework that bridges symbolic reasoning and task-space motion con-

trol, enabling the transparent execution of household manipulation tasks through a tightly integrated reasoning

and control loop. At its core, this framework allows any symbolic theory to be ”plugged in” with a reasoning

module to create interpretable robotic controllers. This modularity makes the framework flexible and applica-

ble to a wide range of tasks, providing traceable feedback and human-level interpretability. We demonstrate

the framework using a qualitative theory for pouring with a defeasible reasoner, showcasing how the system

can be adapted to variations in task requirements, such as transferring liquids, draining mixtures, or scraping

sticky materials.

1 INTRODUCTION

In robotics, the demand for systems that are both

transparent and interpretable has become increas-

ingly essential, particularly in safety-critical applica-

tions. Although data-driven methods, including mul-

timodal foundation models for robot control, have

demonstrated exceptional performance in tasks that

require generalization and semantic reasoning, their

decision-making processes remain opaque (Brohan

et al., 2023). This lack of transparency complicates

introspection, debugging, and maintenance. Such

challenges are especially concerning in dynamic set-

tings where robots must operate safely, reliably and

adaptively, with decision-making processes that are

traceable and comprehensible, such as in household

environments.

At the same time, we challenge the common view

that qualitative inference is merely a compromise

for achieving higher-order goals like interpretability.

While quantitative precision remains important, hu-

a

https://orcid.org/0009-0008-5880-6484

b

https://orcid.org/0000-0002-0419-5242

c

https://orcid.org/0000-0002-1304-581X

d

https://orcid.org/0000-0002-0066-1904

e

https://orcid.org/0000-0002-7888-7444

∗

These authors contributed equally to this work.

man skill acquisition suggests that qualitative, sym-

bolically describable knowledge plays a fundamental

role in mastering complex motor tasks. Symbolic de-

scriptions not only support learning through language

and communication but also serve as a means to ab-

stract and transfer knowledge across tasks and envi-

ronments. By embracing qualitative inference, we

enable robots to adapt to task variations and environ-

mental changes more robustly, a property often lack-

ing in purely data-driven systems. For example, while

reinforcement learning agents can achieve superhu-

man mastery in specific games, their policies often

fail when faced with even trivial changes in the game

environment (Kansky et al., 2017) — highlighting the

importance of qualitative, causal knowledge for gen-

eralization.

This paper introduces a novel control framework

that bridges symbolic reasoning and full-body robot

motion control, enabling the interpretable execution

of household manipulation tasks through tightly in-

tegrating symbolic reasoning into a motion control

loop. At its core, the framework enables a variety of

symbolic theories, that satisfy certain requirements,

to be ”plugged in” with a reasoning module into a

motion controller to create interpretable robotic con-

trollers. The requirements will be outlined in this pa-

per. Once connected, the reasoning module generates

actionable decisions, while the control system exe-

886

Huerkamp, M., Dhanabalachandran, K., Pomarlan, M., Stelter, S. and Beetz, M.

A Modular Framework for Knowledge-Based Servoing: Plugging Symbolic Theories into Robotic Controllers.

DOI: 10.5220/0013394400003890

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 17th International Conference on Agents and Artificial Intelligence (ICAART 2025) - Volume 1, pages 886-897

ISBN: 978-989-758-737-5; ISSN: 2184-433X

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

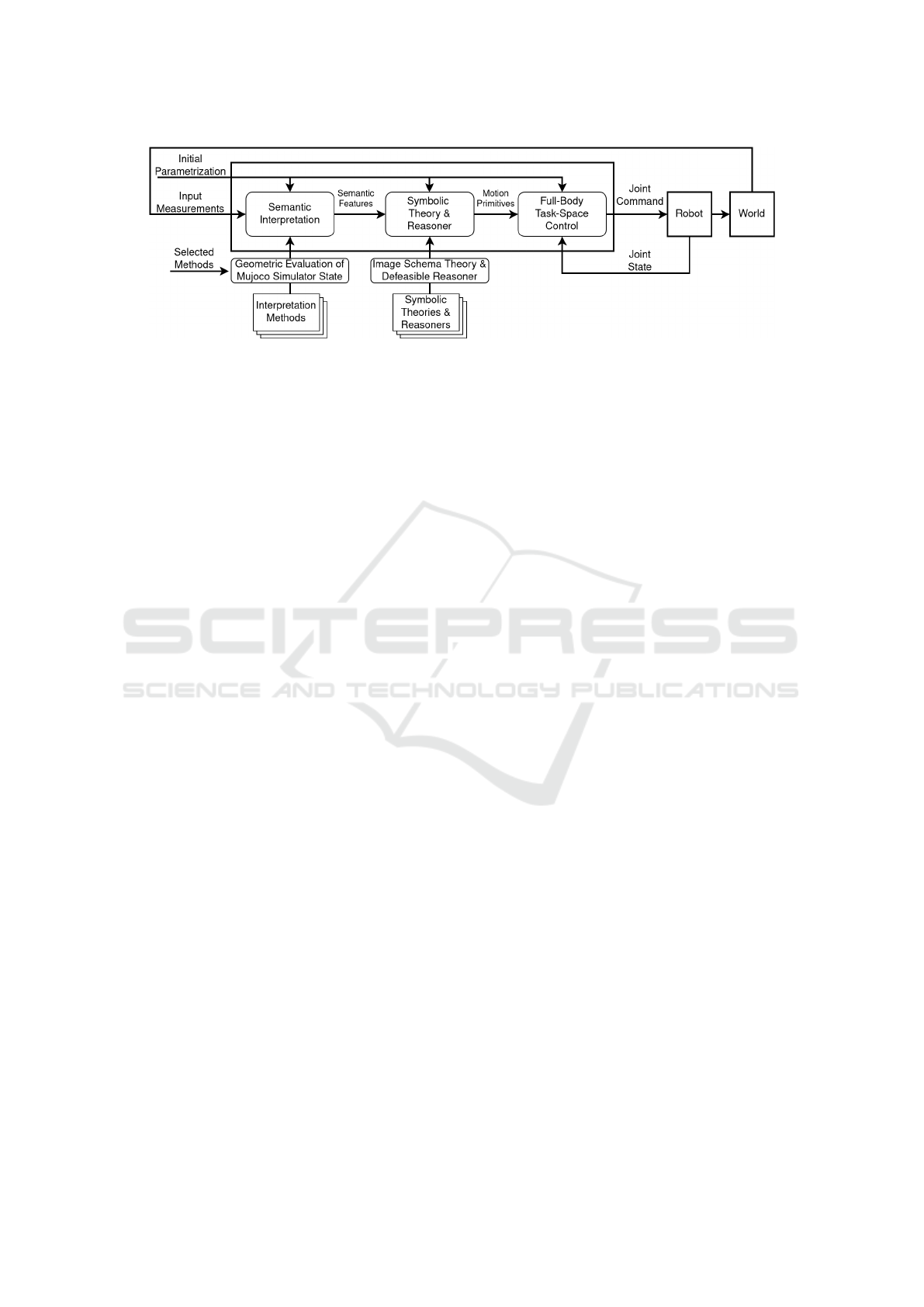

Figure 1: Conceptual overview of the knowledge-based servoing framework and the semantic interpretation and reasoning

methods we selected for the examples in the evaluation section.

cutes them in real time. This modularity makes the

framework applicable to a wide range of tasks, pro-

viding traceable feedback, human-level interpretabil-

ity, and a opportunity for robust knowledge transfer

between tasks and environments.

We demonstrate the framework using a symbolic

theory for pouring, based on a concept from cognitive

science called image schemata (Mandler, 1992). Im-

age schemata, as dynamic patterns of spatial relations

and movements, provide a vocabulary to describe sit-

uations at an abstract level while capturing function-

ally relevant aspects, such as containment, support,

or linking of objects. By leveraging image schemata,

our understanding of spatial arrangements in terms of

the affordances they enable, prevent, or manifest, and

how relative movements between objects impact task

goals can be expressed as a set of rules on symbolic

predicates. The rule-based formalism we use for that

is called defeasible logic (Antoniou et al., 2000). Fur-

thermore, we apply the basic rule set developed for

pouring, on the tasks of draining mixtures and scrap-

ing sticky materials by adapting the initial rule set

based on our understanding of the new task. However,

the framework is not limited to pouring or defeasible

logic. By design, it supports the integration of multi-

ple symbolic theories, making it extensible to diverse

tasks and environments. Through this plug-and-play

capability, our framework promotes a systematic ap-

proach to developing transparent robotic controllers

for complex, real-world applications.

The contributions of this paper are:

1. A modular control framework that integrates sym-

bolic reasoning and control, enabling the execu-

tion of tasks through pluggable symbolic theories.

2. A demonstration of the framework’s flexibility

and transparency using a rule-based theory de-

rived from image schemata concepts to reason

about pouring processes.

3. An evaluation of the system’s adaptability across

robots, environments, and task variations, high-

lighting trade-offs between performance and

transparency.

This work establishes a foundation for

knowledge-based servoing, a paradigm inspired

by visual servoing but extended to symbolic rea-

soning. By combining qualitative inference with

real-time execution, the proposed framework em-

powers robots to perform complex tasks with

transparency, adaptability, and robust generalization,

while facilitating the transfer of knowledge across

tasks and environments.

The next section explains the basic idea and

the assumptions we made for different parts of the

knowledge-based servoing framework. Section 3

presents related work and section 4 explains the rea-

soning method used for the pouring example. After-

wards, section 5 details the integration of symbolic

reasoning with a task space control method. Then

we present the evaluation of different pouring tasks

in section 6 and end with the conclusion in section 7.

2 THE KNOWLEDGE-BASED

SERVOING PARADIGM

Visual servoing in robotics uses visual feedback to

guide movements by connecting observed image fea-

tures to control parameters through a mathematical

model (Chaumette and Hutchinson, 2006). While ef-

fective for precision tasks, it is limited by its reliance

on visible image features and struggles due to occlu-

sions in partially observable environments.

In knowledge-based servoing, on the other hand,

we want to operate on semantic features (also called

facts) of the environment, the task, and the robot. Se-

mantic features can be extracted from, but are not lim-

ited to, vision. Other sensor modalities such as tactile

or force/torque sensors can also be used. Different

modalities can provide a measurement for the same

semantic feature in case one modality is unavailable,

A Modular Framework for Knowledge-Based Servoing: Plugging Symbolic Theories into Robotic Controllers

887

e.g. due to occlusion. In the example of pouring, a

simple semantic feature would be that the destination

container is not filled to the desired level, therefore

pouring has to continue.

To achieve knowledge-based servoing, real-time

reasoning preceded by a suitable semantic interpreta-

tion layer has to be integrated into the control loop.

Figure 1 shows a diagram of the proposed architec-

ture. The semantic interpretation layer filters all input

modalities for the facts that are relevant for the used

symbolic theory. The theory is then evaluated based

on the perceived facts and the results are forwarded to

a full-body task-space controller that moves the robot

accordingly. As in visual servoing, where there ex-

ist multiple methods for feature detection, the design

of the interaction matrix, or the direct calculation of

image differences, it should be possible to use a va-

riety of symbolic theories in knowledge-based servo-

ing. More specifically, we want to design the integra-

tion in the control loop in a way that supports a ”plug-

and-play” like change of symbolic theories from a li-

brary that is part of the robot’s knowledge base. To

realise that, assumptions and requirements for each

module of the control cycle have to be defined and

satisfied.

2.1 Assumptions and Requirements

First, for any symbolic theory to be applicable, a set

of input values i.e. facts has to be defined once for the

specific symbolic theory and then grounded in every

step of the control cycle. Therefore, as usual in vi-

sual servoing, the control cycle starts with perceiving

data that are then semantically interpreted into rele-

vant facts. The discretized information is then ana-

lyzed by the symbolic reasoner based on the provided

theory to infer the desired movement of the robot. Be-

cause of the discretization of the data and the absence

of a concrete mathematical model, it is not possible

to calculate the desired movement in terms of a con-

tinuously valued output value. Instead, the reasoner

has to infer a set of motion primitives that the motion

controller has to realize. This has the advantage that

motion primitives could be arbitrary complex, if the

employed motion controller supports them. For the

sake of generality, we propose to choose motion prim-

itves that can be transformed into a desired task frame

twist. Second, the symbolic theory has to be solvable

sufficiently fast by the used reasoner. The same holds

for the semantic interpretation of perceived data.

The dependence on motion primitives requires the

controller to be able to execute each primitive alone

or as a composition of multiple ones. It also has to be

able to smoothly switch from one primitive to another

in one control cycle. A class of motion controllers

that can to do this are task-space control frameworks

that solve a quadratic optimization problem for in-

stantaneous joint velocities or torques (Mansard et al.,

2009), (Aertbeli

¨

en and De Schutter, 2014), (Bou-

yarmane et al., 2018), (Stelter et al., 2022a), (Corke

and Haviland, 2021), (Escande et al., 2014). This

way, the combination of all active motion primitives

can be represented as a desired task frame twist that

can change abruptly at every control cycle. A desired

twist can be defined for multiple task frames to realize

dual arm manipulation or to control the field of view

of head mounted cameras. They can also be combined

with other tasks to enforce safety constraints like joint

limits and collision avoidance.

3 RELATED WORK

Symbolic inference methods have been used in

robotics mostly for aspects of behavior that corre-

spond to high levels of abstraction, such as task plan-

ning; a survey on the state of the art, with a fo-

cus on declarative and logic based methods, is given

in (Meli et al., 2023). Because robot behaviors must

take into account both constraints at higher levels of

abstraction as well as constraints imposed by geom-

etry and physics, the field of Task And Motion Plan-

ning (TAMP) is very active, and a recent survey is

provided by (Guo et al., 2023). Outside of planning,

logic-based methods have been employed either to de-

scribe “controller” specifications – “controller” here

meaning a state machine guiding paths in a discrete

transition system – as in (Kress-Gazit et al., 2011)

or to specify rules with which to select a next ac-

tion as in (Xiao et al., 2021; Lam and Governatori,

2013; Ferretti et al., 2007; Shanahan and Witkowski,

2001); several of these papers even present applica-

tions of defeasible logic in robotics. In general, in the

cited papers, inference operates on highly abstracted,

atomic actions loosely coupled with what lower-level

control actually does. A more direct connection be-

tween symbolic logic and control is explored in (Lin-

demann and Dimarogonas, 2019) where specifically

designed temporal properties of control barrier func-

tions are used to satisfy signal temporal logic tasks.

Their design requirements limit the set of feasible sig-

nal temporal logic expressions, while we aim for an

approach where more general symbolic theories can

be used. For that reason the evaluations of formal

guarantees for our control system, as it is done in the

field of formal synthesis, is outside the scope of this

paper.

A framework with a stronger focus on robotics ap-

IAI 2025 - Special Session on Interpretable Artificial Intelligence Through Glass-Box Models

888

plications is presented in (Muhayyuddin et al., 2017),

where ontologies and physics based motion planning

are combined with linear temporal logic (LTL) spec-

ifications. The knowledge-based framework can con-

sider the capabilities of the robot during LTL verifi-

cation and physics-based motion planning to realize

the planning of long-horizon tasks that might require

the manipulation of obstacles. In contrast, we are fo-

cused on the control of local manipulation tasks rather

than long horizon tasks and motion planning. Still,

we see great benefit in embedding our framework in

an overarching planning system for the initial param-

eterization based on given task requests, especially if

digital twins of the environment and the robot are used

to evaluate the outcome of different parameterizations

beforehand. Here, the symbolic theory embedded in

the controller provides a benefit in automatic debug-

ging of the robots behavior. But this is outside the

scope of this paper.

In regards to the closed-loop control of our run-

ning example, the pouring task, significant advances

have been made in pouring liquids using tactile infor-

mation (Piacenza et al., 2022) or vision (Zhu et al.,

2023), (Schenck and Fox, 2017), (Dong et al., 2019).

However, these methods primarily focus on adjusting

the tilt angle based on fill-level feedback. This is in

contrast to our work, which is a control system capa-

ble of accommodating various forms of feedback. In

the case of pouring, this includes the fill level of par-

ticipating containers, if spilling has occurred, and if

the placement of the containers allows pouring. To

the best of our knowledge, there exists no motion

control system that includes these types of feedback

in closed-loop pouring control while also consider-

ing the tasks for draining of mixtures and scraping

of sticky materials. Motion planning for pouring with

a fluid dynamics model in (Pan et al., 2016) implic-

itly considers the placement between containers, but

lacks real-time capabilities due to the high computa-

tional demand of the fluid model.

4 SYMBOLIC THEORIES

PLUGGABLE INTO ROBOT

CONTROL

In this section we give an example of a suitable sym-

bolic theory for our framework. Therefore, we out-

line the contents of a theory that qualitatively rea-

sons about the physics of pouring, and the inference

method we have chosen for the evaluation examples

in this paper.

4.1 Qualitative Theories of Physics

To be applicable to the knowledge-based servoing

framework, a theory has to operate on qualitative facts

asserted by perception, infer high level descriptions

of the situation, and activate or suspend motion prim-

itives that are then converted to desired twist values.

While perception and control modules are then tasked

to interface the quantitative world with the qualitative,

we now turn to the contents of this qualitative repre-

sentation.

The relevant level of abstraction at which a theory

for knowledge-based servoing should operate is that

of the presence/absence and (im)possibility of motion

between objects. For the constitution of such a theory,

we have used notions from cognitive science: image

schemas and affordances.

Image schemas are suggested in cognitive linguis-

tics to play a complex role: on the one hand, they

are sensorimotor patterns of embodied experience, on

the other they abstract away from quantitative de-

tails while preserving functional aspects of a sce-

nario (Johnson, 1987). Examples of image schemas

include Linkage, Containment, Support. Thus, image

schemas provide us with a vocabulary with which to

describe object interactions, at a level where one can

answer questions such as, are objects moving apart

from each other, can they move apart from each other,

will they move together if one of them moves etc.

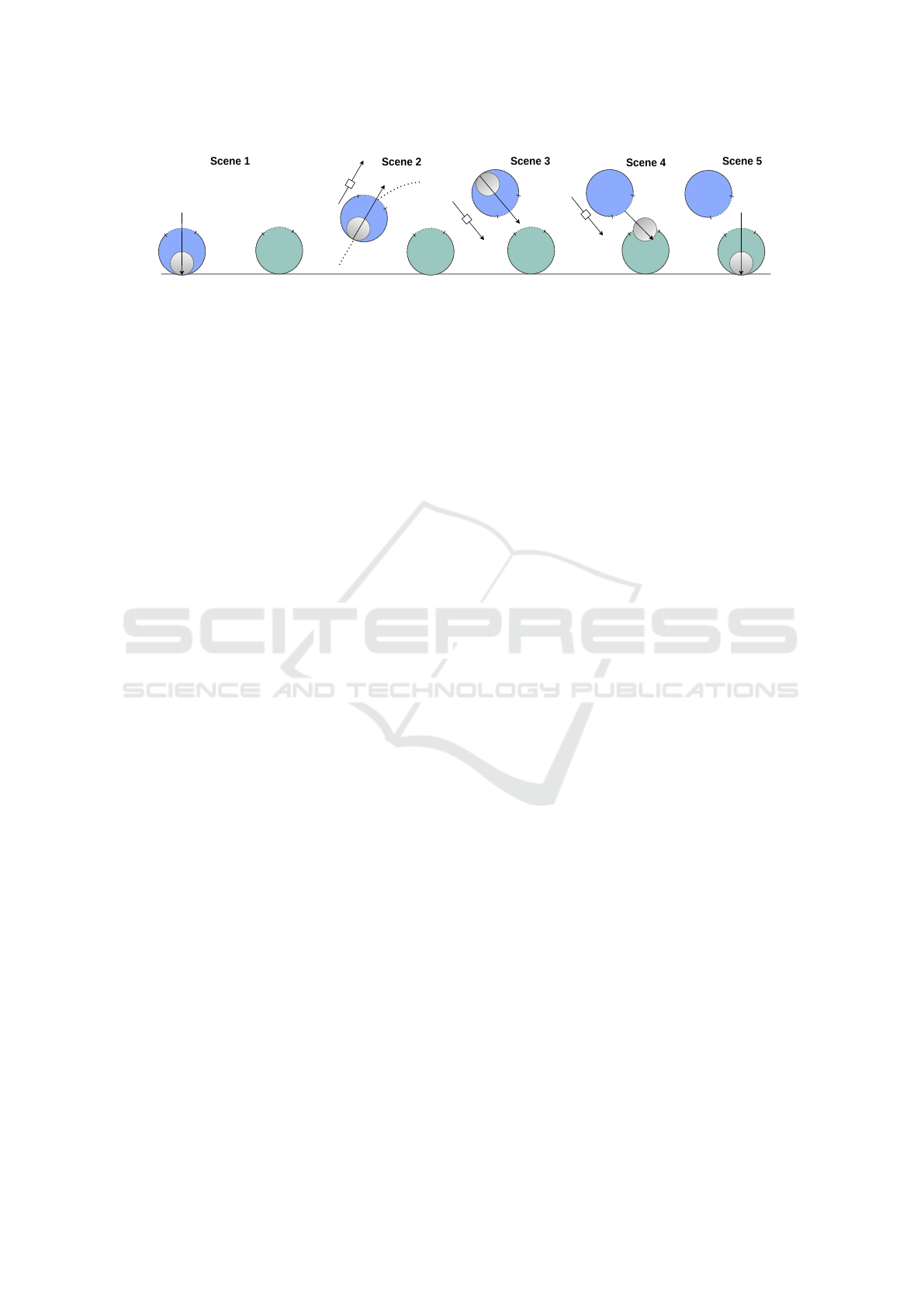

To illustrate how image schemas may describe a

timeline of events, consider a prototypical pouring

scenario shown in Figure 2, which proceeds through a

sequence of scenes characterized in qualitative terms.

Particulars of shape or coordinates are abstracted

away, but the various steps along the sequence – sep-

arated by differences in which image schematic rela-

tions are present – capture the functionally relevant

aspects of pouring. The image schematic description

contains information about necessary conditions for

something to happen. In the example, for the con-

tents to exit or enter a container (scene 4) it must pass

through the container’s boundary, and this boundary

must not be blocked for this to be possible. The im-

age schematic description implies expectations of ob-

served behavior. In the figure, because the contents

are contained (scenes 1, 2), we expect it to move to-

gether with the container (scene 2). Such expectations

may fail to materialize for reasons yet invisible to the

robot, but they are important to indicate what a de-

fault course of events would be, and thus guide per-

ception and monitoring systems to select what kinds

of queries are relevant to answer.

While the above focuses more on object interac-

tion, affordances bring the robot and its actions into

A Modular Framework for Knowledge-Based Servoing: Plugging Symbolic Theories into Robotic Controllers

889

Figure 2: Image schematic segmentation of a pouring event. Scene1: Substance is contained inside source and the source

affords CONTAINMENT. Both source and destination are FAR and VERTICAL. Scene2: Source MOVE UP and NEAR

destination. Source is not VERTICAL anymore. The arrow with □ indicates a caused movement. Scene3: Source MOVE

TOWARDS destination and there is no BLOCKAGE. Scene4: Substance goes OUT of source and IN to the destination.

Substance has a SOURCE-PATH-GOAL. Scene5: Substance is contained inside destination and the destination affords CON-

TAINMENT.

the picture. Affordances are what an environment

provides to an agent in terms of possibilities for ac-

tion (Gibson, 1977). Reasoning with affordances en-

ables answering questions related to what actions are

possible, what their effects would be, and what other

objects i.e. tools should be involved in the action.

Our theories then infer image schematic descrip-

tions based on qualitative facts asserted by perception,

and in so doing infer expectations about how these ob-

jects can and will act. They infer affordances based on

the image schematic description, select or tune mo-

tion primitives based on the inferred affordances, and

emit queries to perception to verify that expectations

implied by the image schematic descriptions are met.

Using square brackets to index by discrete time

steps, the integration of reasoning into the larger

perception-control loop and its embedding into the

world can then be summarized as:

X[k + 1] = ENV (X[k],U[k])

Y [k + 1] = SEMINT (X[k + 1], Q[k])

S[k] = SCHMOD(Y [k])

U[k] = INV MOD(S[k], G)

Q[k] = FW DMOD(S[k],U [k], G)

In the above, X is the quantitative state of the

world, U a description of which motion primitives

are active for the robot, and ENV is a function that

quantitatively updates the state of the environment. Y

are qualitative facts about observed object movements

and spatial relations, Q is a description of percep-

tion queries to run, and SEMINT is a function from

environment state to qualitative observations. Each

of SCHMOD, INVMOD, FWDMOD are collections

of rules. SCHMOD infers image schemas and af-

fordances from observed qualitative facts. INVMOD

acts as a physics inverse model to infer the motion

primitives to execute. FWDMOD acts as a physics

forward model to infer what to expect and thus what

to query for in the next time step. In the above,

G stands for a set of facts characterizing the robot’s

overarching goal for the task, here assumed to be sta-

ble for the duration of the task.

Facts that need to be inferred for the theory we

employ in this paper are the relative poses of two

containers and geometric reasoning about how close

they and their openings are; if there is outflow from

the source container; if there is spilling; is the pour-

ing goal is reached. The set of motion primitives is

{moveLeft, moveRight, moveUp, moveDown, move-

Forward, moveBack, increaseTilting, decreaseTilting,

rotateLeft, rotateRight}.

4.2 Defeasible Inference

As qualitative reasoning leaves detail out, its conclu-

sions will not be always true. Cups can contain water,

except when they cannot – because of being cracked

or turned upside down, etc. Therefore, a robot must

always watch what the world actually does and re-

act accordingly. However, it is also helpful to rep-

resent and reason with exceptional cases when these

are known. A logical formalism which allows this

and does so efficiently is defeasible logic (Antoniou

et al., 2000). It allows inferring what would typically

be thought true in a situation but allows retraction of

conclusions when additional information is given. A

defeasible theory is represented by (R, >), with R be-

ing a finite set of defeasible rules and ’>’ a superiority

relation among the rules. Defeasible inference pro-

ceeds by adding a conclusion to a provability chain

when there is no undefeated objection to that conclu-

sion remaining in the theory. Contradictory conclu-

sions (e.g. p and its negation, denoted −p) object to

each other. An objection is defeated when all the rules

supporting it are inapplicable or overruled by superior

applicable rules. A rule is applicable if all of the terms

in its condition are facts or have already been added

to the provability chain.

IAI 2025 - Special Session on Interpretable Artificial Intelligence Through Glass-Box Models

890

A simple example of a defeasible theory which

showcases the default and exceptions pattern is given

below:

r : Container(?x) ⇒ canContain(?x)

s : Cup(?x) → Container(?x)

r

′

: Broken(?x) ⇒ −canContain(?x)

r

′

> r

”⇒” represents a defeasible implication, i.e. a con-

clusion that could be retracted upon further informa-

tion, but seems the best one given the available data

right now. In the rules, variable names begin with a

’?’. Binding variables in a rule to entities in a robot’s

situation grounds the rule, and defeasible inference

will proceed only on grounded rules. The theory

states that Containers can contain, Cups are Contain-

ers but a broken cup cannot contain.

We then constructed a defeasible rule set to en-

code a qualitative theory for pouring in a general way.

As an example of a rule about what can happen and

what can we expect to observe, consider a scenario

in which the affordance to pour is met and the tilt

motion has been carried out. According to the im-

age schematic sequence of events during pouring, the

contents will be out. This expectation about the state

is defined as an attention query to check if the con-

tents are out.

Source(?s), Destination(?d), canPourTo(?s, ?d),

isTilted(?s) ⇒ Query contentsOut(?s, ?d)

If the contents are not out from the source as expected

then the concluded motion primitive for the controller

is to react by increasing the tilting of the source.

Source(?s),Destination(?d), canPourTo(?s, ?d),

isTilted(?s), -contentsOut(?s, ?d)

⇒ Perform IncTilting(?s)

By reasoning about expected facts the perception

module could be optimized to not calculate facts that

are not expected, which would result in intelligently

deciding when to utilize which sensor for what pur-

pose.

5 DESIGN OF THE MOTION

CONTROL METHOD

To link the output of the reasoner to a task space

control method, the higher level planning component

that selects the symbolic theory and initializes the

reasoner, also has to initialize a task space control

interface with the correct structure to interpret the

feedback provided by the reasoner. For the exam-

ple of pouring this includes defining the tilt direction

n

t

∈ R

3

, the rotation direction for rotating a container

around its height axis n

z

∈ R

3

, velocity gain param-

eters (α, β, γ), which task frame should be controlled,

and a common reference frame.

From a mathematical perspective, the reasoner

provides a set of motion primitives where each primi-

tive corresponds to a movement along or about an axis

of a reference frame summarized as a set of Boolean

values B = {x

+

, y

+

, z

+

, x

−

, y

−

, z

−

,t

+

,t

−

, r

+

, r

−

} ∈

[0, 1]. For example, x

+

indicates that the controlled

task frame should move along the x-axis of the com-

mon reference frame in the positive direction, t

+

indi-

cates that the task frame should rotate about the posi-

tive tilt direction transformed into the common refer-

ence frame, and r

+

indicates the same for the positive

rotation about the rotation direction. The desired tool

frame twist ξ ∈ R

6

received from the reasoning com-

ponent is constructed as:

ξ

d

=

v

d

ω

d

=

α(x

+

− x

−

)

α(y

+

− y

−

)

α(z

+

− z

−

)

n

t

(βt

+

− γt

−

) + n

z

β(r

+

− r

−

)

(1)

where v

d

, ω

d

∈ R

3

are the desired translational and

rotational velocity, respectively.

The desired tool frame twist is then integrated as a

constraint in a quadratic problem of the general form

min

s

s

T

Hs

s.t. l

A

< As < u

A

l < s < u

(2)

Details are presented in (Stelter et al., 2022b) where

the motion control method we employ here is ex-

plained, but in a nutshell, s = (

˙

q, c) are the robot’s

instantaneous joint velocities and slack variables for

constraint relaxation, respectively. H is a diagonal

weight matrix describing the importance of the joints

relative to each other and to the slack variables. The

slack variable weights describe how expensive it is

to violate their corresponding constraints. A contains

the Jacobians of the task spaces. In this scenario,

the task space describes the task frame pose with re-

spect to the common reference frame. This makes As

the task space velocity, i.e., the task frame twist with

our chosen task space. A also adds one slack vari-

able to each constraint to allow the solver to violate

constraints, this is important to avoid infeasibility. l

A

and u

A

contain the lower and upper limits for the task

space velocity, i.e., ω

d

in our example. l and u contain

joint velocity limits.

A Modular Framework for Knowledge-Based Servoing: Plugging Symbolic Theories into Robotic Controllers

891

6 EVALUATION

In this section, we evaluate the utility of our frame-

work in the context of pouring and variations of that

task. Pouring serves as an ideal example of the frame-

work’s pluggability, as each task variation—rooted

in a single abstract concept—introduces unique re-

quirements while preserving transferable task knowl-

edge. This highlights the efficiency of only adapt-

ing the decision-making process by plugging in dif-

ferent symbolic theories rather than developing sim-

ilar control structures for each task. The task varia-

tions we investigate are pouring from one container

to another, draining one substance from a pot while

retaining another, and scraping sticky objects from a

cutting board. In the standard pouring task, we eval-

uate whether our proposed system works at all, dis-

cuss accuracy and performance trade-offs, and show

the interpretability of our control system by evaluat-

ing the symbolic theory at different snapshots of the

task execution.

In the second experiment, we show how altering

the symbolic theory based on the human understand-

ing on how a task should be solved enables our control

system to solve a novel task variation.

In the third experiment, we extend the theory to

more motion primitives and the control structure to

two controlled task frames, to showcase the extended

applicability of our framework. The experiments are

assessed in a simulated environment to ensure that vi-

sion algorithms for sensing container fill levels and

spillages do not become the limiting factor in our

evaluation. The related work section has discussed

works that do this and future work will investigate

how we can integrate their solutions for perception

in the real world. In the following, we briefly intro-

duce the general setup and then discuss the individual

experiments in detail.

6.1 Experimental Setup

As a simulation environment, we use Mujoco with

models of the bimanual mobile robot PR2 and the

one-armed mobile Human Support Robot (HSR) from

Toyota. The liquid in the simulated scenes is approx-

imated by adding particles with a radius of 0.5cm to

the source containers. The task-space controller and

the reasoner are configured to run with a control fre-

quency of 50hz and 10hz, respectively. The reasoner

could run with a significantly higher frequency but it

has to run slower than the task-space controller for a

stable control loop. The velocity gains in (1) are set

to α = 0.02, β = 0.03, γ = 1 for all subsequent exper-

iments.

6.2 Pouring Between Containers

For pouring between containers, we created a Mujoco

scene in which two cups are placed on a table, Fig-

ure 3. The PR2 and HSR then grasp the cup filled

with particles with one hand. Then the proposed con-

trol system is initialized and the desired amount of

particles is poured into the other cup. During initial-

ization, the system is parameterized to act on a coor-

dinate frame at the center of the grasped cup, and the

reasoner receives information about the action (pour-

ing), the relevant objects (two cups), and the goal (to

fill the destination with 40 particles).

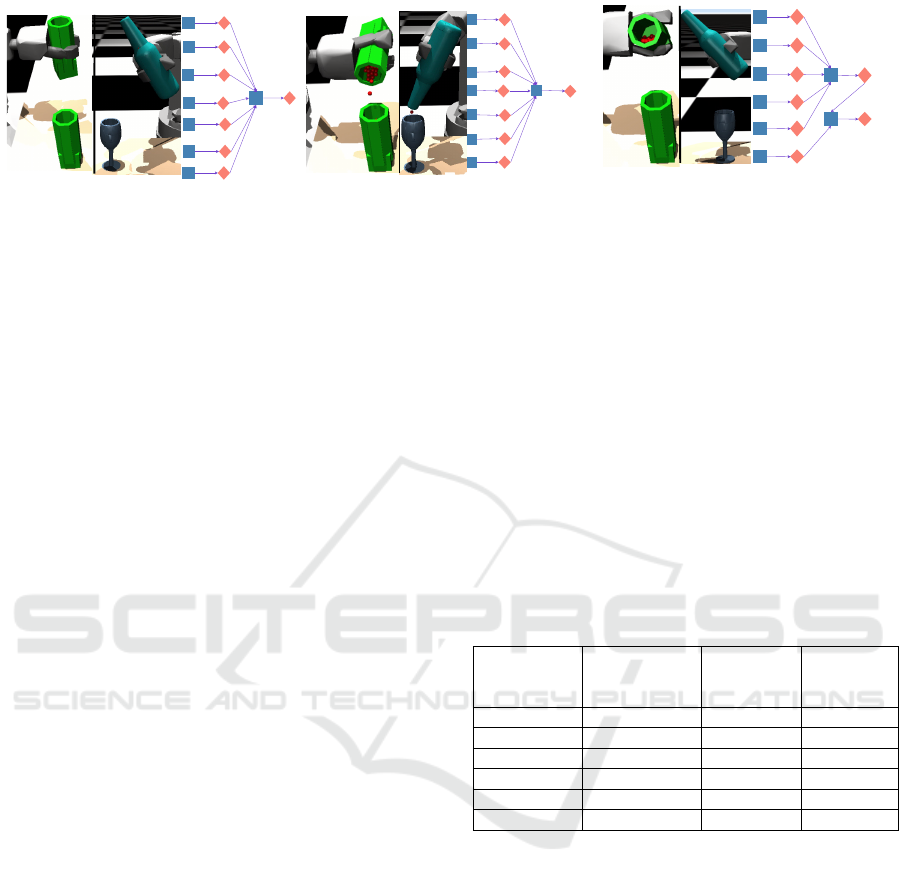

Snapshots in Figure 3 shows the critical stages of

the pouring task and how the reasoner and the con-

troller handle them together. In the initial stage on

the left, the source cup is held upright above the des-

tination cup. The openings of the source cup and the

destination cup are not yet arranged properly, and the

destination is to the left of the source. Therefore, the

reasoner concludes to command the motion primitive

moveRight to progress toward satisfying the initial

condition for pouring, that is, to align the opening of

the source container with respect to the destination

container.

In the second picture, the first cup is already pour-

ing into the second cup. The reasoner is aware of

this and is therefore observing the particles and the

fill level of the destination container with correspond-

ing queries to the semantic interpreter. As the cup is

tilted and the particles are moving out, the reasoner

observes a slow flow of the contents and hence con-

cludes that the source cup has to be tilted more to ac-

celerate the pouring action.

In the last picture, the first cup is tilted back to

stop pouring. This happens because the affordance to

pour is no longer needed as the desired goal state is

achieved. In addition to that, the reasoner concludes

decreaseTilt until the cup is upright. When the cup is

upright and the goal is reached, the reasoner will not

activate any motion primitive to indicate the end of

the task execution.

We executed this experiment 60 times with differ-

ent goal conditions, starting positions of the source

cup around the destination cup, and different sliding

friction coefficients for the particles. See Table 1 for

the results. The tilt direction was automatically de-

termined as either a leftward or rightward tilt from

the gripper’s perspective, depending on whether the

source cup was located to the right or left of the des-

tination cup. All runs were successful, but on average

the system always overshot the desired amount of par-

ticles. The most overshoot happened for low goals, as

the particles tend to come out in a bulk and our system

IAI 2025 - Special Session on Interpretable Artificial Intelligence Through Glass-Box Models

892

+Perform

IncreaseTilting(cup1)

+SourceRole

(cup1)

+DestinationRole

(cup2)

+poursTo(cup1,cup2)

+slowFlowFrom

(cup1,cup2)

-goalReached

(cup2)

-hasEdges(cup1)

+Pouring(pouring1)

+SourceRole(cup1)

+DestinationRole

(cup2)

+goalReached(cup2)

-hasEdges(cup1)

-canPourTo

(cup1, cup2)

+Pouring(pouring1)

-upright(cup1)

+PerformDecrease

Tilting(cup1)

+SourceRole(cup1)

+DestinationRole

(cup2)

-hasOpeningWithin

(cup1,cup2)

+rightOf(cup2,cup1)

-goalReached

(cup2)

-hasEdges(cup1)

+Pouring(pouring1)

+PerformMove

Right(cup1)

Figure 3: Three different stages of a pouring task with the reasoner’s inference for that stage. In the reasoning graph, boxes

indicate rules and diamonds refer to the inferred predicates. The shown graphs are curated snapshots from the full evaluated

state of the defeasible reasoner to show the inference process of a specific movement primitive. Normally, multiple movement

primitives can be inferred at the same time. The reasoning process is the same for pouring from a bottle to a wineglass or

from a cup to a cup.

will react a touch too late to stem the flow, once this

flow is observed. In contrast, state of the art liquid

volume estimation in combination with a PID con-

troller for the rotation of a source container around

one axis achieves final goal errors of below one per-

cent (Zhu et al., 2023). This is a significant difference

from our best performing scenarios of pouring 100

particles with an average final goal error of approxi-

mately six percent. Conversely, we do have full trans-

parency of the decision-making of the control system,

while controlling all degrees of freedom of the source

container with a mobile robot, and we also start every

pouring run from a different position 50-100cm away

from the destination container. Furthermore, this is

not an inherent weakness of our framework, rather

than a limitation of the employed symbolic theory.

A theory adapted for precision pouring could include

rules for a more precise flow control to achieve bet-

ter results. For a fair comparison of that claim, we

would have to integrate the same fill level measure-

ment method as the related work in our future works.

Looking at the spilling rates, our system is able

to adapt the pouring pose accordingly to avoid fur-

ther spilling, but this does not include singular par-

ticles that occasionally spill, as they are not classi-

fied as spillage. Therefore, some amount of spillage

must occur for our system to react to it. That the

system is capable of reacting to spilling can be seen

by the low amount of particles that are spilled com-

pared to the number of all particles in the cup (140).

Another mode of spilling occurs when the cup is al-

ready pouring without spilling, but the reasoner com-

mands to move the cup to avoid potential spilling. As

the velocity gains are fixed, the subsequent movement

can be too fast, which causes spilling of some parti-

cles. Therefore, future work should explore reason-

ing about the velocity gain to react slower or faster

in some situations, or a continuous output for veloc-

ity gains. The related works did not measure spillage

rates.

An interesting observation happened when the cup

was tilted to the left, the HSR reached a position limit

in its wrist rotation joint, theoretically preventing it

from tilting any further. The Full-Body controller

solved this by using the combined movement of the

arm and the base of the HSR to realize the full pouring

movement. Highlighting the importance of full-body

task space control for household robots in contrast to

optimizing one specific degree of freedom with a PID

controller.

Table 1: Outcomes of pouring different quantities of parti-

cles from various positions. Experiments were conducted

with the HSR and two cups(see Figure 3). For each row, ten

runs were performed; we present the average and standard

deviation of particles exceeding the goal or being spilled.

Goal Goal Error [#] Spilling [#]

Sliding

Friction

Coefficient

10 particles 12.6 ±2.46 1.4 ±1.35 1

40 particles 13.1 ±6.42 7.5 ±7.67 1

100 particles 6.2 ±3.49 9.3 ±6.67 1

10 particles 10.3 ±8.65 6.4 ±10.04 3

40 particles 18.7 ±8.08 6.3 ±5.6 3

100 particles 5.5 ±5.99 8.2 ±6.86 3

6.3 Draining from a Pot

Draining is a variation of pouring in the sense that one

substance is poured from a source container, while

a second substance with different physical properties

should stay within the source container. This is sim-

ulated by placing a larger ball in a pot with 100 other

particles, as seen in Figure 4. The larger particle has

a higher friction coefficient, so it is possible to sepa-

rate both substances by pouring. Moreover, since the

container in this instance is a cuboid, pouring from

one of its corners offers greater control and precision

compared to pouring along the edges. Based on this

feature of the pot, a lower corner of the tilted pot is

aligned toward the destination. This is encoded in the

employed symbolic theory that extends the standard

theory for pouring. A further extension is that when-

A Modular Framework for Knowledge-Based Servoing: Plugging Symbolic Theories into Robotic Controllers

893

ever the pot is tilted, the position of the large particle,

the retained substance, is monitored to tilt back when-

ever it is too close to the rim. To execute the draining

task, the pot is grasped with both grippers of the bi-

manual PR2 and then the proposed system is initial-

ized. It is parameterized to control the task frame in

the center of the pot, and the reasoner is initialized

with the action (draining), the relevant objects (seen

in Figure 4), and the goal (pour 40 particles and have

the large particle retained in the pot).

The effects of the adapted symbolic theory can be

seen on the right side of Figure 4, where the conclu-

sion to tilt back when the retained substance is close

to the rim of the pot allows the reasoner to deactivate

the fact that pouring is possible whenever the large

particle is in danger of falling out of the pot. This in

turn leads the reasoner to conclude the tiltBack mo-

tion primitive, as the pot should not be tilted when it

is not possible to pour, which causes the large particle

to move away from the edge of the pot, which in turn

reactivates the fact that pouring is possible. This leads

to a cycle that continues until enough particles are in

the destination container.

Table 2: Outcomes of draining different quantities of par-

ticles from initially 100 particles. Experiments were con-

ducted with the PR2 and two pots (see Figure 4). The goal

describes the umber of particles that should be in the des-

tination pot. For each row, ten runs were performed; we

present the average and standard deviation of poured parti-

cles deviating from the goal and being spilled.

Goal Goal Error [#] Spilling [#]

10 particles 4.6 ± 4.7 0.3 ±0.49

40 particles 3.9 ± 3.21 1.2 ±1.14

70 particles 1.2 ± 1.48 2.5 ±1.9

100 particles −9.8 ± 3.77 5 ±3.6

We also executed this experiment 40 times with

different goal amounts of particles that should be

drained from one pot to another. The results can be

seen in Table 2. The data show, that in general the

error is lower than that for pouring. This is due to

the different opening of the pot, where fewer particles

come out in bulk at once. Also, the trends of over-

shooting the goal and that the higher the goal is, the

lower the error continues. An exception to this is the

case where all 100 particles should be drained from

the source pot into the destination pot. Here, the sys-

tem always under performs; due to the particles that

are spilled, they cannot be drained into the pot any-

more, and due to a few particles that are held back

by the larger ball and will not fall out. Therefore, we

stopped draining after about 3 minutes in each run.

When deducting the spilled particles from the goal er-

ror, on average 4.8 particles are left in the source con-

+aligned(bottom-right,

bowl2)

+CornerRegion

(bottom-right)

+Draining(draining1)

+hasEdges

(bowl1)

+PouredSubstance

(liquid1)

+contains(bowl1,

liquid1)

-goalReached

(bowl1)

+QueryCloseTo

Opening(obj1, bowl1)

-closeToOpening

(obj1, bowl1)

+hasLowestOpening

Corner(bowl1,bottom-right)

+Retained

Substance(obj1)

Figure 4: The PR2 draining a pot from a corner, and the

reasoning graph inferring to observe the large green ball to

keep it inside the pot.

tainer. We had to stop the draining controller man-

ually, as this experiment discovered a limitation of

our employed theory, where it did not consider that it

could be impossible to completely empty a container.

Once such a limitation is detected, the design of our

framework allows us to extend the symbolic theory to

deal with the limitation. In the case of the defeasi-

ble rule-based reasoner, we added a rule that negates

that pouring is possible when a small amount of par-

ticles is left in the pot during draining. In this ex-

periment, we set the small amount to be less than six

particles. By assigning it a higher priority than the

rule that makes pouring possible as long as the goal

is not reached, we can successfully handle the discov-

ered limitation.

6.4 Scraping from a Cutting Board

We consider the action of scraping sticky objects from

a cutting board (Figure 5) as a variation of pouring

because it achieves the same effect as tilting the cut-

ting board to transfer something from it into a bowl

when the tilting action alone is not enough. The sticky

cubes on the cutting board are simulated using the ad-

hesion feature of Mujoco. To execute the scraping

task, the cutting board is grasped with one hand and

the second hand is placed at the end of the cutting

board. The system is then initialized with the action

(to transfer), the objects (seen in Figure 5), and the

goal (to transfer two cubes into the bowl). Addition-

ally, this desired twist constraint for the second grip-

per is included in the controller specification:

ξ

d2

=

v

d2

ω

d2

=

ap

+

− ap

−

0

(3)

where 0 ∈ R

5

is a vector consisting of only zeroes.

This constraint is added to the initial twist constraint

that is initialized to act on a frame in the center of the

cutting board. The new constraint moves the coordi-

nate frame of the second gripper back and forth along

IAI 2025 - Special Session on Interpretable Artificial Intelligence Through Glass-Box Models

894

+PerformPush

Towards(obj1,bowl1)

+SourceRole(cuttingboard1)

+DestinationRole

(bowl2)

+supports(cuttingboard1

,obj1)

-goalReached

(bowl2)

+Transferring(transfer1)

+Solid(obj1)

-moveTowards

(obj1, bowl2)

+isTilted(cuttingboard1)

Figure 5: The PR2 scraping sticky cubes from a cutting

board, and the reasoning graph inferring the pushing mo-

tion.

the cutting board. The symbols p

+

, p

−

correspond to

new motion primitives called pushMore and pushLess

that are added to the symbolic theory for the scraping

action. The reasoning procedure is again an extension

of the standard theory for pouring where motion prim-

itives are added for the increased action space of the

task. Figure 5 shows that the cutting board is already

tilted but the objects do not move owing to their stick-

iness, therefore it is concluded that the objects should

be pushed towards the bowl using the added motion

primitives. This could even be extended to control all

degrees of freedom of the the second gripper. But this

example is already sufficient to showcase the flexi-

bility and utility of the proposed knowlede-based ser-

voing framework that is achieved by just converting

the qualitative human understanding of the task into a

tractable set of rules.

7 CONCLUSIONS

In this paper, we introduced knowledge-based ser-

voing as a paradigm for embedding symbolic rea-

soning directly into a closed-loop control frame-

work. Our evaluation in Section 6 focused on a set

of pouring-related tasks (transferring liquids, drain-

ing mixtures, scraping sticky materials) and demon-

strated the framework’s flexibility across varied re-

quirements, robots, and simulation setups. Despite

some performance trade-offs compared to highly spe-

cialized controllers, the approach yielded transpar-

ent task execution and human-understandable failure

modes, illustrating the value of symbolic theories in

robotic control.

Beyond pouring tasks, the framework’s ability to

“plug in” different symbolic theories paves the way

for broader applications in real-world household sce-

narios. The use of defeasible reasoning promotes

straightforward debugging and adaptation, an impor-

tant benefit for robots operating in unstructured envi-

ronments or collaborating safely with humans. As a

result, the methodology can help advance dependable

and trustworthy manipulation solutions, bridging the

gap between high-level cognitive reasoning and pre-

cise motion control.

Looking ahead, a key challenge lies in transi-

tioning from simulation to hardware. Robust per-

ception of semantic features (e.g., fill level or spill

detection) and mitigating occlusions with camera-

based input will require additional sensing modalities

or advanced neuro-symbolic perception techniques

(Pomarlan et al., 2024; De Giorgis et al., 2024),

potentially leveraging large vision-language models.

Moreover, real-world experiments must validate con-

trol frequency and stability to ensure safe deploy-

ment. Nonetheless, the demonstrated resilience of our

motion controller across different robots provides a

strong foundation for further exploration, including

more complex tasks and domains.

In summary, knowledge-based servoing offers a

path toward robotics systems that can be both versa-

tile and interpretable. By coupling symbolic reason-

ing with real-time control, this framework highlights a

promising avenue for enabling robots to adapt to new

tasks, explain their decisions, and ultimately perform

household manipulation in a manner that is both ef-

fective and transparent.

ACKNOWLEDGEMENTS

This work was supported by the German Re-

search Foundation DFG, as part of Collaborative

Research Center (Sonderforschungsbereich) 1320

Project-ID 329551904 “EASE - Everyday Activity

Science and Engineering”, University of Bremen

(http://www.ease-crc.org/). The research was con-

ducted in subprojects “R04 – Cognition-enabled exe-

cution of everyday actions” and “P01 – Embodied se-

mantics for the language of action and change: Com-

bining analysis, reasoning and simulation” This work

was also supported by the European Union’s Horizon

2020 research and innovation program under grant

agreement No 101017089 as part of the TraceBot

project.

REFERENCES

Aertbeli

¨

en, E. and De Schutter, J. (2014). etasl/etc: A

constraint-based task specification language and robot

controller using expression graphs. In 2014 IEEE/RSJ

International Conference on Intelligent Robots and

Systems, pages 1540–1546.

A Modular Framework for Knowledge-Based Servoing: Plugging Symbolic Theories into Robotic Controllers

895

Antoniou, G., Billington, D., Governatori, G., Maher, M. J.,

and Rock, A. (2000). A family of defeasible reasoning

logics and its implementation. In Proceedings of the

14th European Conference on Artificial Intelligence,

ECAI’00, page 459–463, NLD. IOS Press.

Bouyarmane, K., Chappellet, K., Vaillant, J., and Khed-

dar, A. (2018). Quadratic programming for multirobot

and task-space force control. IEEE Transactions on

Robotics, 35(1):64–77.

Brohan, A., Brown, N., Carbajal, J., Chebotar, Y., Chen,

X., Choromanski, K., Ding, T., Driess, D., Dubey,

A., Finn, C., Florence, P., Fu, C., Arenas, M. G.,

Gopalakrishnan, K., Han, K., Hausman, K., Herzog,

A., Hsu, J., Ichter, B., Irpan, A., Joshi, N., Julian, R.,

Kalashnikov, D., Kuang, Y., Leal, I., Lee, L., Lee, T.-

W. E., Levine, S., Lu, Y., Michalewski, H., Mordatch,

I., Pertsch, K., Rao, K., Reymann, K., Ryoo, M.,

Salazar, G., Sanketi, P., Sermanet, P., Singh, J., Singh,

A., Soricut, R., Tran, H., Vanhoucke, V., Vuong, Q.,

Wahid, A., Welker, S., Wohlhart, P., Wu, J., Xia, F.,

Xiao, T., Xu, P., Xu, S., Yu, T., and Zitkovich, B.

(2023). Rt-2: Vision-language-action models transfer

web knowledge to robotic control. In arXiv preprint

arXiv:2307.15818.

Chaumette, F. and Hutchinson, S. (2006). Visual servo con-

trol. i. basic approaches. IEEE Robotics & Automation

Magazine, 13(4):82–90.

Corke, P. and Haviland, J. (2021). Not your grandmother’s

toolbox–the robotics toolbox reinvented for python. In

2021 IEEE International Conference on Robotics and

Automation (ICRA), pages 11357–11363. IEEE.

De Giorgis, S., Pomarlan, M., and Tsiogkas, N. (2024).

ISD8 Tutorial Report: Cognitively Inspired Reason-

ing for Reactive Robotics-From Image Schemas to

Knowledge Enrichment.

Dong, C., Takizawa, M., Kudoh, S., and Suehiro, T. (2019).

Precision pouring into unknown containers by ser-

vice robots. In 2019 IEEE/RSJ International Confer-

ence on Intelligent Robots and Systems (IROS), pages

5875–5882.

Escande, A., Mansard, N., and Wieber, P.-B. (2014). Hierar-

chical quadratic programming: Fast online humanoid-

robot motion generation. The International Journal of

Robotics Research, 33(7):1006–1028.

Ferretti, E., Errecalde, M., Garcia, A., and Simari, G.

(2007). An application of defeasible logic program-

ming to decision making in a robotic environment.

In Logic Programming and Nonmonotonic Reasoning

(LPNMR), pages 297–302.

Gibson, J. J. (1977). The theory of affordances. In Robert

E Shaw, J. B., editor, Perceiving, acting, and know-

ing: toward an ecological psychology, pages pp.67–

82. Hillsdale, N.J. : Lawrence Erlbaum Associates.

Guo, H., Wu, F., Qin, Y., Li, R., Li, K., and Li, K.

(2023). Recent trends in task and motion planning

for robotics: A survey. ACM Comput. Surv., 55(13s).

Johnson, M. (1987). The body in the mind: The bodily basis

of meaning, imagination, and reason. The body in the

mind: The bodily basis of meaning, imagination, and

reason. University of Chicago Press, Chicago, IL, US.

Kansky, K., Silver, T., M

´

ely, D. A., Eldawy, M., L

´

azaro-

Gredilla, M., Lou, X., Dorfman, N., Sidor, S.,

Phoenix, S., and George, D. (2017). Schema net-

works: Zero-shot transfer with a generative causal

model of intuitive physics.

Kress-Gazit, H., Wongpiromsarn, T., and Topcu, U. (2011).

Correct, reactive, high-level robot control. Robotics &

Automation Magazine, IEEE, 18:65 – 74.

Lam, H.-P. and Governatori, G. (2013). Towards a model

of uavs navigation in urban canyon through defeasible

logic. J. Log. and Comput., 23(2):373–395.

Lindemann, L. and Dimarogonas, D. V. (2019). Control

barrier functions for signal temporal logic tasks. IEEE

Control Systems Letters, 3(1):96–101.

Mandler, J. M. (1992). How to build a baby: Ii. conceptual

primitives. Psychological review, 99(4):587.

Mansard, N., Stasse, O., Evrard, P., and Kheddar, A. (2009).

A versatile generalized inverted kinematics imple-

mentation for collaborative working humanoid robots:

The stack of tasks. In International Conference on Ad-

vanced Robotics (ICAR), page 119.

Meli, D., Nakawala, H., and Fiorini, P. (2023). Logic pro-

gramming for deliberative robotic task planning. Ar-

tificial Intelligence Review, 56.

Muhayyuddin, Akbari, A., and Rosell, J. (2017). Physics-

based motion planning with temporal logic specifica-

tions. IFAC-PapersOnLine, 50(1):8993–8999. 20th

IFAC World Congress.

Pan, Z., Park, C., and Manocha, D. (2016). Robot motion

planning for pouring liquids. Proceedings of the In-

ternational Conference on Automated Planning and

Scheduling, 26(1):518–526.

Piacenza, P., Lee, D., and Isler, V. (2022). Pouring by feel:

An analysis of tactile and proprioceptive sensing for

accurate pouring. In 2022 International Conference

on Robotics and Automation (ICRA), pages 10248–

10254.

Pomarlan, M., De Giorgis, S., Ringe, R., Hedblom, M. M.,

and Tsiogkas, N. (2024). Hanging around : Cogni-

tive inspired reasoning for reactive robotics. In Formal

Ontology in Information Systems : Proceedings of the

14th International Conference (FOIS 2024), number

394 in Frontiers in Artificial Intelligence and Applica-

tions, pages 2–15.

Schenck, C. and Fox, D. (2017). Visual closed-loop control

for pouring liquids. In 2017 IEEE International Con-

ference on Robotics and Automation (ICRA), pages

2629–2636.

Shanahan, M. and Witkowski, M. (2001). High-level

robot control through logic. In Castelfranchi, C. and

Lesp

´

erance, Y., editors, Intelligent Agents VII Agent

Theories Architectures and Languages, pages 104–

121, Berlin, Heidelberg. Springer Berlin Heidelberg.

Stelter, S., Bartels, G., and Beetz, M. (2022a). An open-

source motion planning framework for mobile manip-

ulators using constraint-based task space control with

linear mpc. In 2022 IEEE/RSJ International Confer-

ence on Intelligent Robots and Systems (IROS), pages

1671–1678. IEEE.

IAI 2025 - Special Session on Interpretable Artificial Intelligence Through Glass-Box Models

896

Stelter, S., Bartels, G., and Beetz, M. (2022b). An open-

source motion planning framework for mobile manip-

ulators using constraint-based task space control with

linear mpc. In 2022 IEEE/RSJ International Confer-

ence on Intelligent Robots and Systems (IROS), pages

1671–1678. IEEE.

Xiao, W., Mehdipour, N., Collin, A., Bin-Nun, A. Y., Fraz-

zoli, E., Tebbens, R. D., and Belta, C. (2021). Rule-

based optimal control for autonomous driving. In Pro-

ceedings of the ACM/IEEE 12th International Con-

ference on Cyber-Physical Systems, ICCPS ’21, page

143–154, New York, NY, USA. Association for Com-

puting Machinery.

Zhu, F., Hu, S., Letian, L., Bartsch, A., George, A., and Fa-

rimani, A. B. (2023). Pour me a drink: Robotic pre-

cision pouring carbonated beverages into transparent

containers. arXiv preprint arXiv:2309.08892v2.

A Modular Framework for Knowledge-Based Servoing: Plugging Symbolic Theories into Robotic Controllers

897