Exploring Endothelial Cell Adhesion to High-Resolution 3D Printing

Materials for Advanced Organ-on-Chip Fabrication

Steffen Winkler

1 a

, Xenia Kraus

1 b

, Jasmin Huber

1

and Janina Bahnemann

1,2 c

1

Institute of Physics, University of Augsburg, 86159, Augsburg, Germany

2

Center for Advanced Analytics and Pre Augsburg, 86159, Augsburg, Germany

janina.bahnemann@uni-a.de

Keywords: Biocompatibility, 3D Printing, Cell Adhesion, Endothelial Cells, Organ-on-Chip.

Abstract: With advancements in resolution, 3D printing is emerging as a transformative technology for the rapid fabri-

cation of cell culture systems, including organ-on-chip platforms. For successful integration into cell culture

environments, 3D printing materials must not only exhibit general biocompatibility but also support direct

cell adhesion for on-chip cultivation. In this study, we investigated the adhesion of human umbilical vein

endothelial cells (HUVECs) to two 3D printing materials, AR-M2 and M2S-HT90, under varying sterilization

conditions involving heat steam sterilization and ethanol disinfection. Our findings reveal that specific com-

binations of these sterilization techniques significantly enhance cell adhesion, achieving levels comparable to

standard cell culture plates. However, alterations in the 3D printing mode resulted in a complete loss of cell

adhesion, underscoring the critical impact of printing parameters on the material surface properties.

1 INTRODUCTION

Organ-on-chip (OOC) systems simulate increasingly

complex tissue and organ functions and serve as

novel cell culture platforms – enabling both a deeper

understanding of (patho)physiological processes in

academia and industrial applications such as drug dis-

covery. They are increasingly recognized for their es-

sential role in mimicking the complexity of tissues

and organs, thereby enhancing the physiological rel-

evance of experimental results (Leung et al., 2022).

Traditionally, OOCs are microfluidic systems that

consist of microchannels and chambers enabling ac-

tive perfusion of the culture with medium. Fabrica-

tion of microfluidic systems remains a considerable

challenge. Traditional manufacturing techniques are

time- and cost-intensive such as soft lithography, mi-

cro-milling, injection molding, and etching, which

necessitate the use of highly specialized equipment

and cleanroom facilities.

Recent advancements in 3D printing have intro-

duced promising alternatives for fabricating OOCs

more cost-effectively and with reduced developmen-

tal timelines (Meyer et al., 2023; Siller et al., 2020).

a

https://orcid.org/0000-0001-7386-9477

b

https://orcid.org/0000-0002-1186-5443

c

https://orcid.org/0000-0002-7008-1673

Nonetheless, there are only few peer-reviewed stud-

ies evaluating the biocompatibility of 3D-printed ma-

terials that can be printed in high-resolution (Siller et

al., 2019; Winkler et al., 2022). Biocompatibility as-

sessments are typically conducted according to estab-

lished guidelines, such as the International Organiza-

tion for Standardization (ISO) norms (e.g., ISO

10993) and United States Pharmacopeia (USP) Class

VI standards.

Despite these assessments, the direct growth of

cells on 3D-printed materials – specifically the adhe-

sion of cells to the material surface – is rarely inves-

tigated, as this is not a mandatory criterion in ISO-

based biocompatibility evaluations. However, cell

adhesion of a given cell line, is crucial for the devel-

opment of OOCs. It facilitates the use of cell culture

systems that are printed in a single step for immediate

on-chip cell seeding. When investigating the adhesion

properties of a 3D printing material, material post-

processing, including the sterilization method, must

be considered, since it can significantly influence the

materials surface properties and the amount of poten-

tially toxic leachables.

Winkler, S., Kraus, X., Huber, J. and Bahnemann, J.

Exploring Endothelial Cell Adhesion to High-Resolution 3D Printing Materials for Advanced Organ-on-Chip Fabrication.

DOI: 10.5220/0013418600003911

In Proceedings of the 18th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2025) - Volume 1, pages 1063-1067

ISBN: 978-989-758-731-3; ISSN: 2184-4305

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

1063

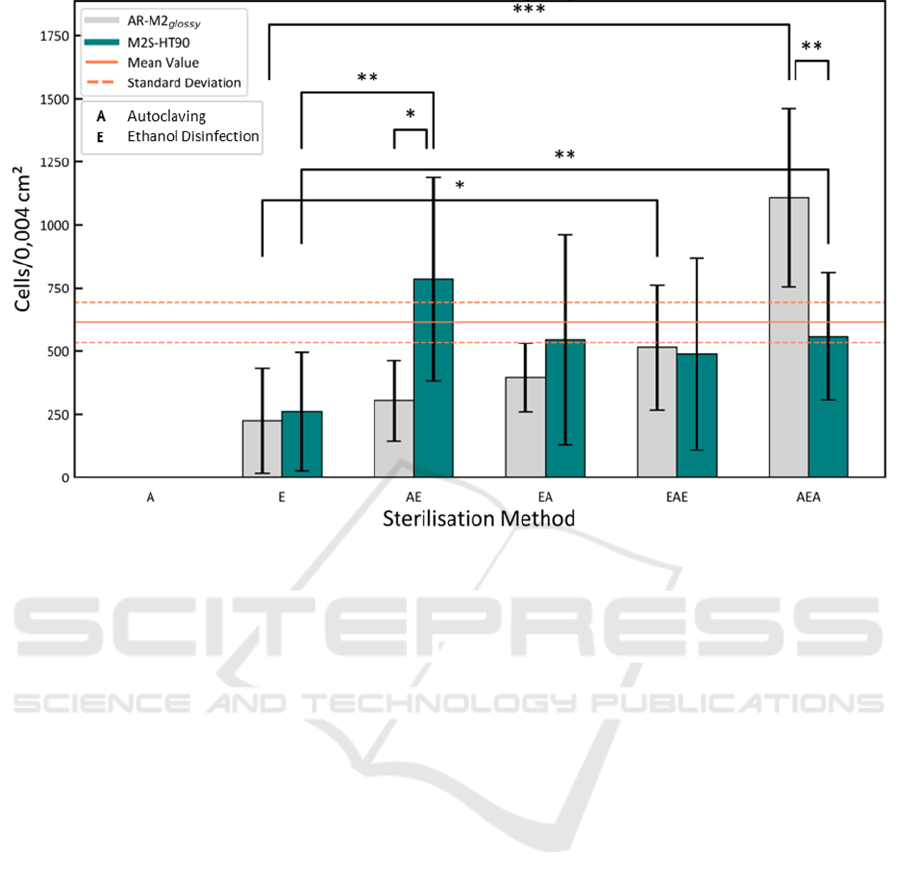

Figure 1: Cell adhesion of human umbilical vein endothelial cells (HUVEC) to material slides of the 3D printing materials

AR-M2 (printed in glossy mode) and M2S-HT90 for different sterilization/disinfection procedures using autoclaving (A)

and/or ethanol (E). Mean and standard deviation of the control is indicated by orange lines. Level of significance as indicated

by asterisks, *p < 0.05; **p < 0.01; ***p < 0.001.

In this study, two materials designed for high-res-

olution 3D printing of microfluidic cell culture sys-

tems were evaluated for their ability to support the

adhesion of human umbilical vein endothelial cells

(HUVEC). The results revealed that different combi-

nations of sterilization methods and printing modes

had a pronounced impact on cell adhesion. The find-

ings underscore the importance of material selection,

post-processing, and evaluation in advancing the de-

velopment of functional and reliable OOCs.

2 RESULTS AND DISCUSSION

Two 3D-printing materials, AR-M2 (printed with

AGILISTA-3200 W) and M2S-HT90 (printed with

ProJet MJP 2500 Plus), were tested for their adhesion

properties to HUVEC. Hence, the cells were culti-

vated on thin 48-well material slides (see Figure S1

in the Appendix), which were sterilized using differ-

ent combinations of heat steam sterilization (auto-

claving, (A)) and ethanol disinfection (E) as two of

the most popular sterilization/disinfection techniques.

Both materials are described by the manufacturers as

biocompatible according to ISO 10993 and/or USP

Class VI and can be printed in high resolution for the

fabrication of microfluidic structures and OOCs.

The cell confluence (as cell count per imaging

area of 0.004 cm²) after 24 h cultivation on AR-M2

(printed in glossy mode) and M2S-HT90 material

slides for different sterilization procedures is summa-

rized as presented in Figure 1. Noticeably, the conflu-

ence increases with an increased number of steriliza-

tion/disinfection steps. Slides that were only auto-

claved (A) facilitated no cell growth at all, while eth-

anol disinfection (E) with 225 ± 208 and 261 ± 234

cells/0.004 cm² shows a significantly impaired adhe-

sion compared to the control with 614 ± 78

cells/0.004 cm². For the M2S-HT90 material all com-

binations of ethanol and autoclaving treatments

showed no significant difference to a 48-well plate

and thus enable the use of the material for direct on-

chip cultivation. Considering these findings, it is hy-

pothesized that potential leachables are increasingly

released to the surface of the material due to the heat

of the autoclaving process and lead to a fully impaired

cell adhesion. In turn, additional extraction by ethanol

removes these leachables and a combination of both

sterilization methods leads to an overall decrease of

leachables inside the material and potential cytotoxi-

city. However, for the AR-M2

glossy

highest confluence

microOrganChip 2025 - Special Session on Organ on Chip Micro-Devices

1064

was found for the AEA sterilization sequence. Since

also ethanol can diffuse into the material, it may not

be removed by subsequent washing steps. The heat of

a second autoclaving step could reduce a possible

negative effect of ethanol and thus further reduces im-

pairments of cell attachment and growth. In addition,

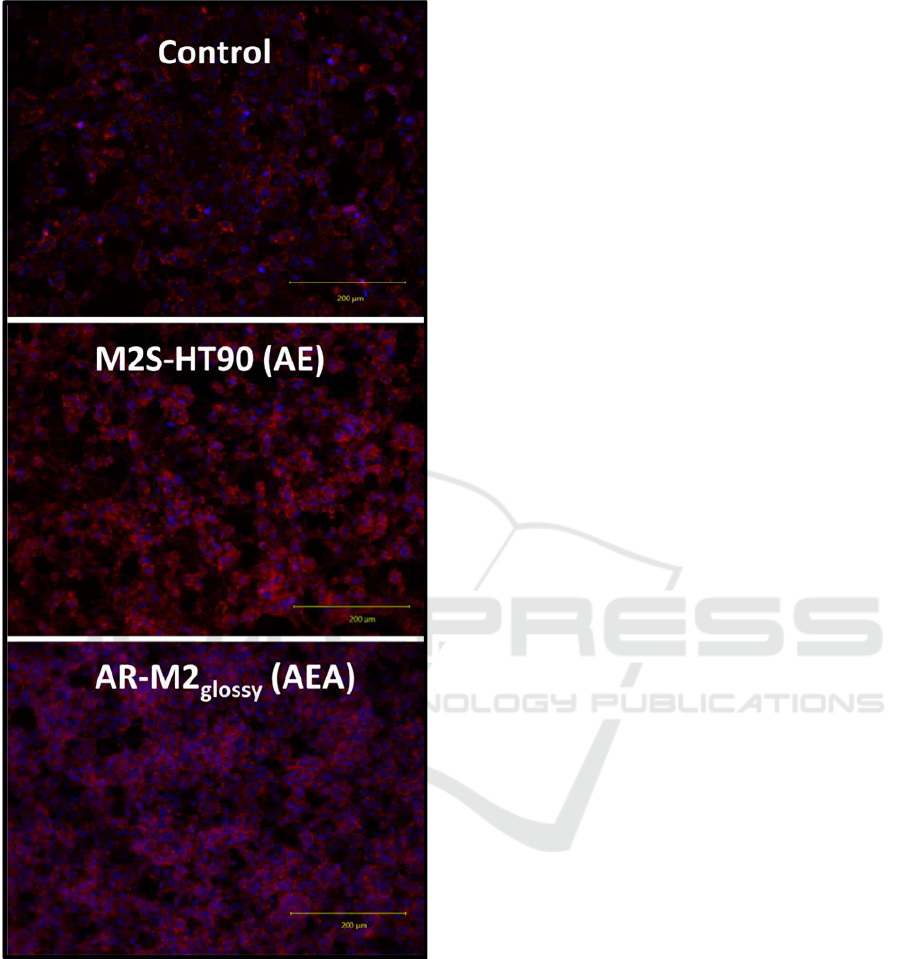

representative images of the control and the best per-

forming sterilization/disinfection procedures are pre-

sented in Figure S2 showing a similar cell distribution

and morphology.

Importantly, the AR-M2 material was also printed

in in the matte printing mode, where in contrast to the

glossy printing mode additional support material co-

vers the top surface of the material slide. Surprisingly,

the change of the printing mode led to a complete loss

of cell adhesion under all tested conditions (data not

shown). This is explained by a complete change of the

surface structure in the matte printing mode, which

increases the surface roughness. The findings demon-

strate the importance of the printing mode and its dra-

matic influence on cell adhesion.

3 CONCLUSIONS

In this work, two materials AR-M2 and M2S-HT90 –

suitable for high resolution 3D printing of microflu-

idic and OOC systems – were investigated on their

adhesion properties to HUVEC using several differ-

ent sterilization procedures. The findings show that

combinations of the sterilization techniques enable

the use of the materials for direct cultivation of HU-

VEC with a comparable confluence to standard cell

culture plates after 24 h cultivation. Furthermore, it

revealed that solely sterilizing by autoclaving or dis-

infecting using ethanol is insufficient and is accom-

panied by an impaired cell attachment. Another key

finding is the strong effect of the printing mode. The

matte printing mode of the AGILISTA-3200 W re-

sults in a loss of cell adhesion at all tested con-

ditions. Since the surface structure in generally

highly dependent on a variety of printing pa-

rameters, change of these parameters can gen-

erally remove or restore cell adhesion of 3D

printing materials.

In contrast to few publications focussing

solely on the biocompatibility using extraction

media according to ISO-10993, we enabled the

use of the printing materials for direct cell

growth on the inner surface of future cell cul-

ture systems. It enables the development of

OOC systems that are fabricated as a single part

removing the need for the integration of exter-

nal materials and thus further reducing fabrica-

tion and development times.

4 EXPERIMENTAL SECTION

4.1 Fabrication and Post-Processing of

3D-Printed Parts

The 3D-printed parts were designed using Solid-

Works 2024 (Dassault Systems Deutschland GmbH,

Germany) and printed using two different high reso-

lution multi-jet 3D printers, the ProJet MJP 2500 Plus

(3D Systems, USA) for printing of the polyacrylate

VisiJet M2S-HT90 (3D Systems, USA) and the

AGILISTA-3200 W (Keyence, Germany) for

printing of the polyacrylate AR-M2 (Keyence,

Germany) material, which was printed in two

configurations, glossy and matte.

Post-processing of the VisiJet M2S-HT90 ma-

terial included removal of the support material Visi-

Jet® M2 Sup (3D Systems, USA) with the following

steps: (1) detachment of the parts from the print plat-

form after 10 min incubation at -20 °C, (2) incubation

in a heat steam bath for 45 min, (3) incubation in a

paraffin oil bath (15 min, 65 °C), (4) incubation in a

ultrasonic paraffin oil bath (15 min, 65 °C), (5) 3x in-

cubation in a ultrasonic bath with ddH

2

O and deter-

gent (15 min, 65 °C) and (6) incubation in an ultra-

sonic bath with ddH2O only (15 min, 65 °C).

Post-processing of the AR-M2 material was per-

formed similarly without step (1-3). The two possible

printing modes glossy or matte were selected by

changing a single setting in the printer software Mod-

elling Studio (Keyence, Germany).

The following methods of sterilization were se-

lected for the experiment: autoclaving at 121°C for 30

min, and treatment with 96% ethanol (VWR, USA) in

various combinations. Treatment with ethanol was

carried out in an ultrasonic bath at 35°C for 1 h, fol-

lowed by an evaporation phase. The printed parts

were then placed in Phosphate Buffered Saline (PBS,

Capricorn Scientific, Germany) at room temperature

for 1 h, and dried.

4.2 Cell Culture Experiments

HUVEC were cultured in EGM-2 (Endothelial cell

growth medium-2, PromoCell, C-22011) in a density

of 6000 cells/cm

2

at 37 °C in a controlled environ-

ment of 5 % CO

2

and ≥ 95 % humidity. Culture me-

dium was supplemented with 10% fetal calf serum

Exploring Endothelial Cell Adhesion to High-Resolution 3D Printing Materials for Advanced Organ-on-Chip Fabrication

1065

(FCS, Capricorn Scientific GmbH, Germany) and

0.5% Gentamycin (VWR, USA).

For biocompatibility testing, HUVEC were

seeded in a density of 4.5 ∙ 10

5

cells/cm

2

on a single

slide of the 3D printing material inside a 48-well plate

(Sarstedt, Germany) (2.86 ∙ 10

5

/well) to reach an es-

timated cell confluence of about 80 % after 24 h cul-

tivation. To fix the slides on the bottom of the plate a

3D-printed cylinder was plugged into the 48-well (s.

Figure S1 in the Appendix). Each condition was per-

formed in triplicate, with 48-well plates devoid of ma-

terial slides serving as the control.

After cultivation, the cells were fixed for 30 min

at RT with 4 % paraformaldehyde (PFA, VWR,

USA) diluted in phosphate buffered saline (PBS)

(Capricorn Scientific, Germany). Cell nuclei were

stained with Hoechst 33342 dye (1:1000, Thermo

Fisher Scientific, Germany). Actin filaments were

stained with Phalloidin iFluor 555 Reagent-Cyto-

Painter (abcam, GBR; diluted 1:1000 in PBS with 1%

BSA (Sigma Aldrich Chemie GmbH, Germany)).

Cells were imaged using a Keyence BZ-X800 flu-

orescence microscope (Keyence, Germany) with a

20x objective. The observed imaging area was

0.004 cm². Cells were counted on three pictures of

each triplicate.

4.3 Statistical Analysis

Each condition was performed in triplicates, with 48-

well plates devoid of material slides serving as the

control. Levels of significance were analyzed using

one-way analysis of variance (ANOVA). Differences

were considered as significant at p < 0.05. Signifi-

cance levels were indicated with *p < 0.05, **p < 0.01

and ***p < 0.001.

ACKNOWLEDGEMENTS

We acknowledge the support by the program “For-

schungspotentiale besser nutzen!” of the University

of Augsburg.

REFERENCES

leung, C. M., Haan, P. De, Ronaldson-Bouchard, K.,

Kim, G.‑A., Ko, J., Rho, H. S., Chen, Z., Habibo-

vic, P., Jeon, N. L., Takayama, S., Shuler, M. L., Vun-

jak-Novakovic, G., Frey, O., Verpoorte, E., &

Toh, Y.‑C. (2022). A Guide to The Organ-On-A-Chip.

Nature Reviews Methods Primers, 2(1).

https://doi.org/10.1038/s43586-022-00118-6

Meyer, K. V., Winkler, S., Lienig, P., Dräger, G., &

Bahnemann, J. (2023). 3d-Printed Microfluidic Perfu-

sion System for Parallel Monitoring of Hydrogel-Em-

bedded Cell Cultures. Cells, 12(14).

https://doi.org/10.3390/cells12141816

Siller, I. G., Enders, A., Steinwedel, T., Epping, N.‑M.,

Kirsch, M., Lavrentieva, A., Scheper, T., &

Bahnemann, J. (2019). Real-Time Live-Cell Imaging

Technology Enables High-Throughput Screening to

Verify in Vitro Biocompatibility of 3D Printed Materi-

als. Materials (Basel, Switzerland), 12(13).

https://doi.org/10.3390/ma12132125

Siller, I. G., Enders, A., Gellermann, P., Winkler, S.,

Lavrentieva, A., Scheper, T., & Bahnemann, J. (2020).

Characterization of a customized 3D-printed cell cul-

ture system using clear, translucent acrylate that ena-

bles optical online monitoring. Biomedical Materials

(Bristol, England), 15(5), 55007.

https://doi.org/10.1088/1748-605X/ab8e97

Winkler, S., Meyer, K. V., Heuer, C., Kortmann, C.,

Dehne, M., & Bahnemann, J. (2022). Invitro biocom-

patibility evaluation of a heat-resistant 3D printing ma-

terial for use in customized cell culture devices. Engi-

neering in Life Sciences, 22(11), 699–708.

https://doi.org/10.1002/elsc.202100104

APPENDIX

Figure S1: CAD of the 3D-printed material slide (bottom)

(9x1 mm) and cylinder (top) (9x15 mm) for the investiga-

tion of the endothelial cell adhesion.

microOrganChip 2025 - Special Session on Organ on Chip Micro-Devices

1066

Figure S2: Representative images (20x objective) of phal-

loidin- and Hoechst 33342-stained HUVECs after 24 h cul-

tivation on 48-well plates as control and M2S-HT90 and

AR-M2

glossy

3D-printed material slides at the best perform-

ing sterilization/disinfection procedures AE and AEA (A:

autoclaving; E: ethanol disinfection).

Exploring Endothelial Cell Adhesion to High-Resolution 3D Printing Materials for Advanced Organ-on-Chip Fabrication

1067