Combining Goal and Process Models for the Specification of

Human-Robot Collaborations

Shaza Elbishbishy

a

, Jeshwitha Jesus Raja

b

, Philipp Kranz

c

and Marian Daun

d

Center for Robotics, Technical University of Applied Sciences W

¨

urzburg-Schweinfurt, Schweinfurt, Germany

Keywords:

Process Modeling, Goal Modeling, BPMN, Human-Robot Collaboration.

Abstract:

Human-Robot collaboration enhances flexibility and efficiency in modern manufacturing. Collaborative robots

work alongside human operators to combine robotic precision with human adaptability. A key challenge is

defining task sequences, managing dependencies, and aligning workflows with strategic goals. This paper

addresses this challenge by integrating goal models with process models. Goal models capture the “why,”

while process models define the “how” in operational workflows. Our approach systematically maps goals to

tasks, ensuring clear traceability and cohesive task execution. We evaluate this method through a collaborative

assembly use case. The integration refines task dependencies, improves coordination, and ensures alignment

between goals and processes. This approach supports efficient human-robot collaboration in semi-automated

manufacturing environments.

1 INTRODUCTION

Collaborative robots (cobots) play a key role in mak-

ing manufacturing processes flexible. They work

alongside other robotic systems to replace parts of

traditional production lines and improve efficiency.

Cobots are cost-effective and adaptable, enabling

Human-Robot Collaboration (HRC) to meet specific

manufacturing needs (Grau et al., 2020). Cobots are

ideal for small batch sizes, where full automation is

too expensive and inefficient. In such cases, semi-

automated setups, where humans and cobots share

tasks, provide a practical solution. This approach

combines human adaptability with robotic precision

to reduce costs and improve flexibility.

In HRC, human operators and cobots operate in

close proximity. They work in parallel or simultane-

ously on the same tasks (Wang et al., 2020). Cobots

assist by handing parts to human operators, or hold-

ing parts in position (Vysocky and Novak, 2016). Hu-

mans, on the other hand, contribute to more complex

tasks that are difficult to automate (Weiss et al., 2021).

It is crucial to plan this interaction in an early de-

velopment phase to ensure that the cobot can work

a

https://orcid.org/0009-0002-0975-272X

b

https://orcid.org/0009-0008-7886-7081

c

https://orcid.org/0000-0002-1057-4273

d

https://orcid.org/0000-0002-9156-9731

alongside the human safely and achieve all intended

goals. To support this, model-based approaches pro-

vide structured methods for analyzing and specifying

such collaborations. These approaches have already

proven valuable in domains like industrial automa-

tion, automotive, and avionics (Est

´

evez and Marcos,

2011; B

¨

ohm et al., 2021), where complex systems re-

quire early planning and clear task definitions to en-

sure success.

Goal modeling is an established approach in re-

quirements engineering (Van Lamsweerde, 2001). It

allows the analysis of goal fulfillment and conflicts

among stakeholders and helps in understanding goals

(hard goals), tasks, dependencies, and interactions

between different systems (Horkoff and Yu, 2011).

While goal modeling is useful in HRC (Daun et al.,

2019), it lacks a clear description of the process logic

in the interaction between human and cobot. In prod-

uct assembly, the cobot and human operator have dis-

tinct tasks, some of which are interdependent while

others can be performed independently. However,

they must be performed in a specific order, which sig-

nificantly impacts the success of the collaboration.

For example, in an assembly process, the cobot

might pick and place parts, but the human operator

can only proceed with the next step (like screwing

parts together) once the parts are correctly placed. If

the cobot places a part out of order or incorrectly, the

human operator’s task may be delayed or need to be

Elbishbishy, S., Jesus Raja, J., Kranz, P. and Daun, M.

Combining Goal and Process Models for the Specification of Human-Robot Collaborations.

DOI: 10.5220/0013432200003928

In Proceedings of the 20th International Conference on Evaluation of Novel Approaches to Software Engineering (ENASE 2025), pages 217-228

ISBN: 978-989-758-742-9; ISSN: 2184-4895

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

217

repeated. Therefore, it is crucial to define and manage

the task sequence early in the development. This en-

sures the process logic is clear and that the tasks align

with the collaboration’s goals.

In this paper, we propose an integrated approach

that derives a process model directly from the goal

model of a Human-Robot Collaborative Assembly

(HRCA) process. We adopt a transformation method-

ology adapted from (Ortiz et al., 2024), systemati-

cally mapping the elements of goal models to con-

structs in process models (Business Process Model

and Notation (BPMN)). This creates a clear and di-

rect traceability between high-level strategic goals

and their operational task execution within the pro-

cess flow. By applying this approach to a use case of

toy truck assembly, we demonstrate its effectiveness

in specifying human-robot task dependencies, refin-

ing process steps, and ensuring cohesive task coordi-

nation. Thereby, this paper contributes an investiga-

tion into whether integrating goal models with BPMN

improves the specification and management of HRCA

by aligning strategic goals (“why”) with operational

workflows (“how”). Through our evaluation, we an-

alyze the extent to which the integrated models fa-

cilitate better goal fulfillment, task traceability, and

collaboration efficiency in semi-automated manufac-

turing environments.

Section 2 introduces works related to the concepts

of the manufacturing industry and HRC, as well as

model-based engineering and model integration. Sec-

tion 3 then presents our three-stage approach, which

begins with defining the objectives of an HRCA using

a goal model. This is followed by deriving a BPMN

from the goal model with the assistance of a trans-

formation table and then refining it. The approach is

evaluated in Section 4 with a case example, the as-

sembly of a toy truck. Finally, Section 5 concludes

the paper and outlines future work.

2 RELATED WORK

In recent years, cobots have become integral to flexi-

ble manufacturing, designed to interact with humans

without safety barriers or protective cages (Matheson

et al., 2019). While cobots offer the flexibility for

quick, cost-effective layout changes, their effective

deployment requires a deep understanding of their

characteristics, which can be a barrier to widespread

industry adoption. Key challenges include organiz-

ing teamwork, facilitating autonomous decisions, and

balancing autonomy with human oversight in tasks re-

quiring conscious judgment (Kem

´

eny et al., 2021).

2.1 Modeling Human-Robot

Collaborations with Goal and

Process Models

To establish safe and reliable HRC, a proper defini-

tion and analysis of HRC is needed in early stages

of development. Therefore, goal modeling has been

shown to be an adequate approach for modeling col-

laborative systems and has been successfully applied

to HRC as well (Daun et al., 2019). In previous work,

we have shown that goal models can particularly be

used to identify and model high-level safety hazards

of the collaboration (Manjunath et al., 2024), and to

define digital twins of robotic systems (Jesus Raja

et al., 2024). In addition, process information is cru-

cial for managing cooperation with cobots (Cherubini

et al., 2016), and are a vital basis for defining coor-

dinated behaviors between multiple actors (Corradini

et al., 2023; Bourr et al., 2021), as well as for ensur-

ing safety in the process (Kranz et al., 2024). How-

ever, these models often focus on later development

phases and may overlook specific HRC dynamics, as

BPMN primarily emphasizes operational aspects over

goal rationales (Ponsard and Darimont, 2019).

Goal and process models play complementary

roles in improving task coordination and efficiency

in HRC. The HRC approach demonstrates how

goal models define strategic objectives, while pro-

cess models represent the operational workflows to

achieve them. The integration of the two ensures that

high-level goals are directly linked to task-level ac-

tivities, enabling effective collaboration between hu-

mans and robots (Lestingi and Longoni, 2016).

Chen et al. use process models to detail task

sequences and dependencies, while goal models de-

termine optimal task allocation between human and

robotic agents (Chen et al., 2011). This ensures that

each task contributes directly to the overall goal and

balances workload effectively. Similarly, another ap-

proach highlights how goal models capture collabo-

ration objectives and process models define the se-

quences and interactions necessary for their execu-

tion. This integration facilitates smooth transitions

between tasks and clarifies roles and responsibilities

(Malik and Bilberg, 2019).

A systematic review emphasizes the importance of

integrating goal models to represent long-term goals

and process models to outline detailed steps required

to achieve these goals. This combined approach al-

lows for better planning and coordination in shared

human-robot workspaces, particularly in scenarios in-

volving dynamic and complex workflows (Sim

˜

oes

et al., 2022). These studies highlight how goal mod-

els define “what needs to be achieved,” while process

ENASE 2025 - 20th International Conference on Evaluation of Novel Approaches to Software Engineering

218

models specify “how tasks are executed,” enabling ef-

fective management of HRCA in industrial environ-

ments.

2.2 Combining Goal and Process

Models

Combining goal models and process models provides

complementary perspectives, offering a more detailed

understanding of system requirements (Amyot et al.,

2022). Approaches like User Requirements Nota-

tion (URN), which integrate goal modeling with pro-

cess modeling, have been applied in various domains,

though they often require adaptation for specific in-

dustries (Daniel Amyot, 2022; Chen, 2007). More re-

cent work by Ortiz et al. (Ortiz et al., 2024) incorpo-

rates goal-oriented modeling with BPMN for micro-

service compositions, ensuring alignment with busi-

ness goals through the modification of processes.

The URN, standardized by the International

Telecommunication Union (ITU-T) in 2008 with im-

proved versions in 2012 and 2018, combines goal

modeling with process modeling, offering both a

graphical and a textual syntax(Daniel Amyot, 2022).

URN facilitates leveraging social modeling in process

design and improvement efforts. Chen et al. proposed

an approach utilizing URN to model goals and pro-

cesses, incorporating key performance indicator mod-

els and integrating a business intelligence tool to mon-

itor and measure business processes, with a focus on

healthcare (Chen, 2007). However, its applicability

beyond healthcare is limited, and it requires adap-

tation for broader business process evaluation. Or-

tiz et al. (Ortiz et al., 2024) introduces an approach

that represents goals in BPMN pools using collapsed

BPMN sub-processes and enables independent devel-

opment and modification of micro-services by trans-

forming Tropos diagrams into structured BPMN dia-

grams, ensuring alignment with business goals.

While URN has seen numerous applications in

academia and industry, additional efforts and edu-

cational initiatives are necessary for broader main-

stream adoption. Customization to specific domains

proves valuable, enabling the use of domain-specific

terminology and syntax, as well as the development

of reusable assets (Daniel Amyot, 2022). The works

discussed above primarily focus on specific domains,

such as health and business. In contrast, our paper

centers on industry automation, particularly in the

context of HRCA.

3 PROPOSED APPROACH

A combination of goal and process models facilitates

a coherent interconnection between the overarching

objectives of the goal model and the intricate process

tasks of the process model. We use the goal-oriented

requirements language (GRL) to specify goals of the

HRCA, as GRL has already been proven useful for

HRC (e.g., (Daun et al., 2023)). For process mod-

els, we rely on BPMN as it is a commonly used lan-

guage, and also has already been successfully applied

in HRC (e.g., (Fernandes et al., 2021)). By map-

ping the notations of GRL and BPMN specifically

for HRCA, we ensure that both models are consistent

with one another.

A goal model can be employed to illustrate the

overarching strategic objectives of an HRCA process,

as well as the subordinate sub-objectives that must be

accomplished in order to attain the respective overar-

ching goal. Such sub-goals may be defined as hard

goals, such as the assembly of sub-assemblies, which

are necessary for the completion of the overall goal

of assembling the finished product. Moreover, soft

goals, such as safe assembly, can also be defined. To

prevent the target models from becoming too com-

plicated, they are often limited to a relatively short

description of the tasks (hard goal ”assembly of sub-

assemblies”, but not the individual steps required for

this). In BPMN, the chronological process flow of

HRCA can be represented in greater detail, with the

option of including individual assembly steps.

Our approach is based on the work of (Ortiz et al.,

2024), who integrate goal models with BPMN. In this

work, we adopt this integrated approach to specify

and manage HRCA, where a human operator and a

cobot perform complementary tasks. The procedure

for transforming a goal model to a BPMN is as fol-

lows:

1. A goal model is created for the overarching goals

of the assembly process, as well as the necessary

soft goals.

2. A first version of the BPMN is then created based

on the transformation table in Figure 2, which is

consistent with the previously created goal model.

3. The BPMN is refined by further specifying tasks.

In our current version, only hard goals are trans-

ferred from goal models to BPMNs. These objectives,

which are tasks within the goal model, are also the

main components of a process flow and can therefore

be transferred with minimal effort. In contrast, ‘soft

goals’ are characterized by their heterogeneity, which

poses a challenge in the standardization of their inte-

gration into a process model.

Combining Goal and Process Models for the Specification of Human-Robot Collaborations

219

3.1 Definition of HRCA Goals with

Goal Models

A goal model is a framework used to represent high-

level objectives and strategic goals within a system.

It decomposes these objectives into smaller sub-goals

and tasks, aligning the system’s actions with the de-

sired outcomes. Goal models are instrumental in cap-

turing the broad goals of HRCA and breaking them

down into specific tasks that human operators and

robots need to execute to achieve the intended goals.

These models help ensure that each task performed,

whether by the human or the cobot, is contributing

towards achieving the overarching goal.

The elements of a goal model for HRCA are:

• Actors: Usually the human and the cobot work-

ing together on the assembly. Furthermore, the

system may be expanded to include additional ac-

tors, such as other tools or machines, or multiple

humans or cobots.

• Goals: High-level objectives that represent the

desired outcomes, such as “Assemble Final Prod-

uct.”

• Sub-Goals: Defined as hard goals, these are more

specific objectives that support high-level goals,

such as “Prepare Sub-Assembly”.

• Soft Goals: Qualitative objectives, such as “Min-

imize Errors” or “Maximize Efficiency,” that in-

fluence multiple tasks.

• Tasks: A breakdown of high-level goals into

smaller, actionable items performed by the actors

cobot and human.

• Self-Dependencies: Dependencies between two

tasks or goals of an actor.

• Dependencies: The interdependence between

two tasks or goals undertaken by different actors.

Such dependencies may be either unidirectional,

pertaining to assembly sequence dependencies, or

bidirectional, denoting collaboration between hu-

man and cobot.

In HRCA, the goal model provides a structured

approach for ensuring that the tasks performed by hu-

man operators and cobots align with the broader goals

of the system. It helps articulate the overall purpose of

the collaboration and ensures each action contributes

to achieving that purpose.

The first step in our approach is to create a goal

model that represents the high-level objectives and

their decomposition into sub-goals and tasks. The

goal model identifies the strategic objectives of the

assembly process and links these objectives with the

Cobot

Actor

Human Goal

Cobot Goal

Task A1

Task A2

Task B1

Task B2

*

AND

D

D

AND

*

Human

Actor

Figure 1: Goal Model of a typical HRCA, showing human

and cobot as actors, their specific goals and the dependen-

cies between the tasks.

tasks that need to be performed by the human operator

and the cobot.

Figure 1 shows an example of a typical HRCA.

The scenario under consideration comprises two ac-

tors, namely the Human Actor and the Cobot Actor.

Furthermore, a superordinate goal is set, the Assem-

bly of the final product. This goal is broken down

into two sub-goals, one for the human actor and one

for the cobot. The aforementioned sub-goals are then

subdivided into discrete tasks, designated Task A1 and

Task A2 for the human actor and Task B1 and Task B2

for the cobot. Moreover, soft goals are defined at the

sub-goal level. Task A2 is dependent on Task A1, just

as Task B2 is dependent on Task B1. The completion

of the cobot’s Task B1 is dependent on the completion

of the human’s Task A2. As the dependency is unidi-

rectional, it is a result of the assembly sequence of the

two tasks.

The goal model also considers soft goals that can-

not be explicitly quantified but influence the overall

collaboration process, such as “Minimize Errors” and

“Maximize Efficiency”. These goals guide the design

of tasks and help to ensure that the collaboration re-

mains effective and smooth.

3.2 Deriving a Process Model from the

Goal Model

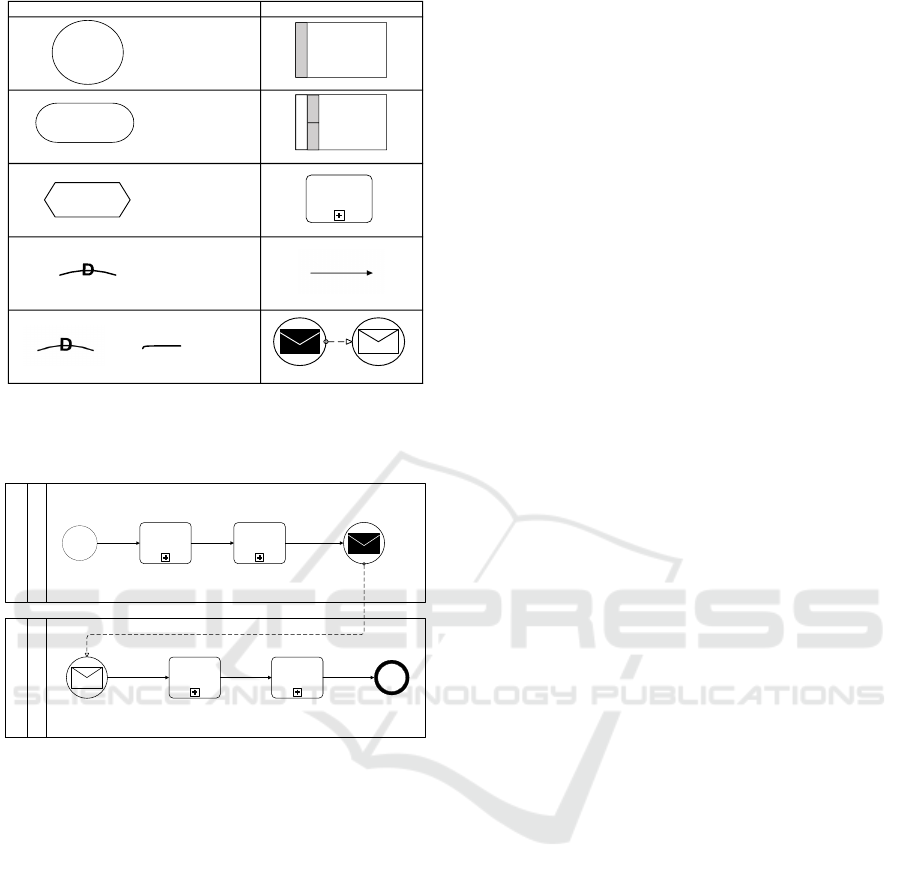

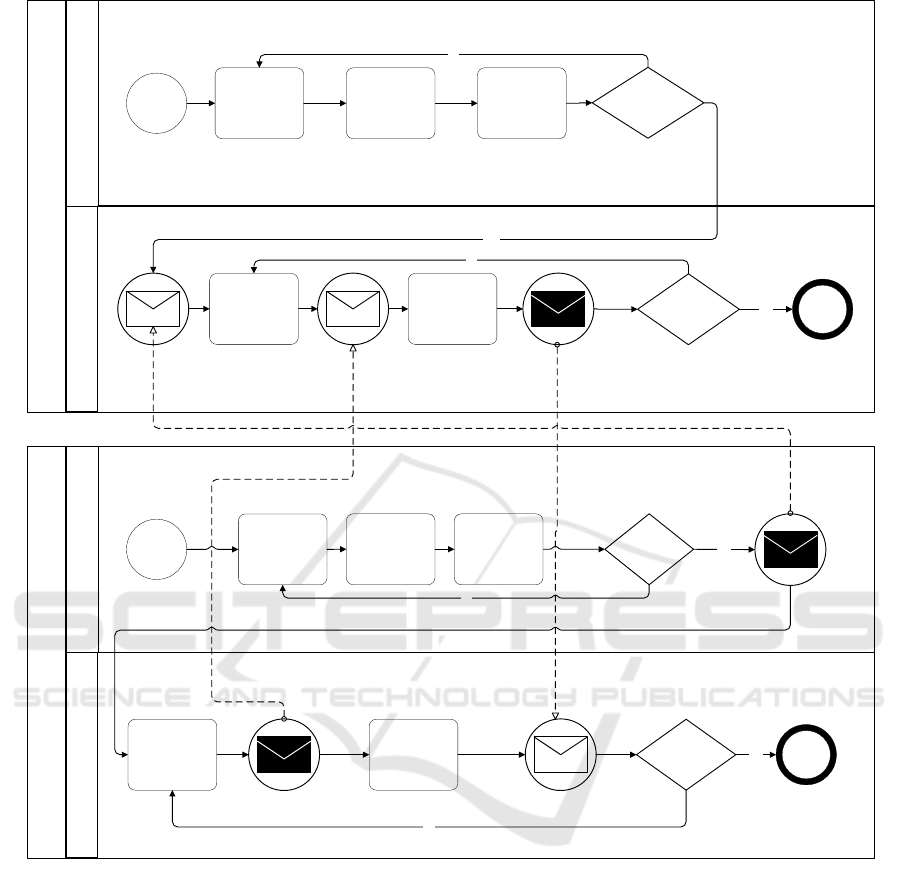

Figure 2 illustrates the correspondence between the

notations of goal models and BPMNs. Our approach

has been informed by the work of Ortiz et al. (Ortiz

et al., 2024), which we have adapted and expanded

to encompass the mapping of additional relevant no-

tations for HRCA. The aforementioned table allows

for the derivation of BPMNs from the previously cre-

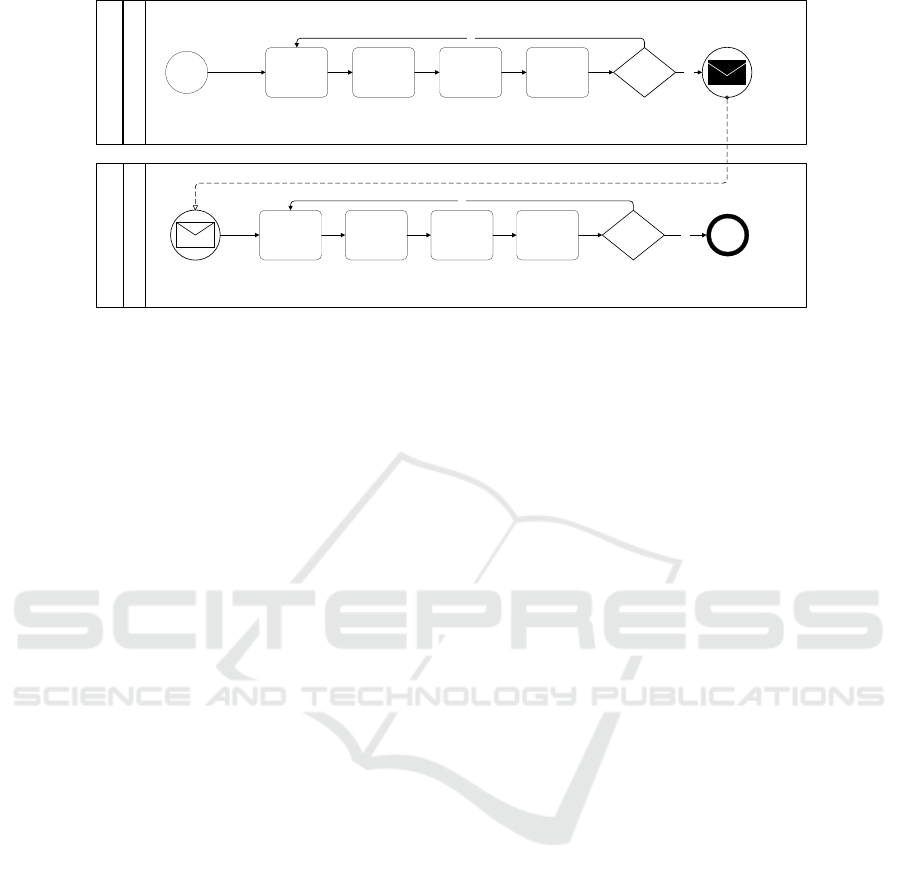

ated goal models. Figure 3 illustrates the BPMN de-

rived from the goal model depicted in Figure 1. The

initial step is to create a pool in the BPMN for each

actor present in the goal model, which includes both

Human Actor and Cobot Actor. Subsequently, the

goals are translated into sub-pools, namely the Hu-

man Goal and the Cobot Goal. The tasks of the

goal model are transformed into collapsed BPMN

ENASE 2025 - 20th International Conference on Evaluation of Novel Approaches to Software Engineering

220

GRL Goal Model Notation

BPMN Notation

Actor Pool

Goal Sub-pool

Task Activity

Self - Depedency Sequence flows

Unidirectional and Bidirectional Dependency Send and receive message

*

D

D

Figure 2: Transformation table to transform goal models

into BPMNs. The mapping was adapted from (Ortiz et al.,

2024) and extended to fit the purposes of HRCA.

Human

Cobot

Human Goal

Cobot Goal

Task A1 Task A2

Task B1 Task B2

Start

End

Send Message

Receive message

Figure 3: BPMN derived from a goal model.

sub-processes, designated as Tasks A1, A2 and Tasks

B1, B2. In the mapping of goals and tasks, we di-

verge from the approach proposed by Ortiz et al., who

map goals to BPMN sub-processes without consider-

ing tasks. The sequence flows of the BPMN result

from self-dependencies within the goal model (for ex-

ample, Task A2 is dependent on Task A1). Dependen-

cies between two different actors are represented ac-

cording to the mapping of Ortiz et al., with connected

send and receive messages based on the type of de-

pendency (for example, Task B1 is dependent on Task

A2).

The transformation of the goal model to the

BPMN creates a direct mapping between high-level

goals and operational tasks in the BPMN diagram.

This framework ensures coherence and allows for

seamless real-time coordination between strategic

goals and operational tasks.

3.3 Refining the Process Model

BPMN is a widely used graphical language designed

to represent the sequence and flow of tasks within a

business or operational process. It provides a stan-

dardized way to model business processes, including

task sequences, roles (human, robot), decision points,

and interactions between process participants. In the

context of HRCA, BPMN serves as an adequate tool

for detailing the specific tasks, decision points, and

dependencies that exist between the human operator

and the cobot, ensuring smooth coordination and col-

laboration.

While goal models provide the high-level objec-

tives of the collaboration, BPMN helps translate these

strategic goals into a task flow, representing how those

goals are achieved in practice. It captures the tasks

performed by both the human and cobot actors, spec-

ifying the order of execution and how these tasks in-

terrelate.

In the third and final step of our approach, we

undertake a further refinement of the BPMN model

derived from the goal model, defining the collapsed

tasks with greater precision. This is done by elabo-

rating on high-level tasks (e.g., A1, A2, B1 and B2)

and refining them into their corresponding low-level

subtasks (e.g., A1.1, A1.2, A2.1, A2.1, B1.1, B1.2,

B2.1, B2.2). This enables the HRCA process flow to

be described in a highly defined manner, encompass-

ing tasks and intricate interactions. The link with the

goal model is still in place, enabling conclusions to be

drawn from the very precisely defined tasks and pro-

cesses via their collapsed tasks back to the superordi-

nate objectives of the goal model without overloading

the goal model itself with these.

Figure 4 illustrates the refined BPMN derived

from Figure 3. In this version, the activities are pre-

sented in greater detail, with all processes decom-

posed into sub-processes. For example, Task A1 is

further divided into Tasks A1.1 and A1.2. The same

decomposition is applied to Tasks A2, B1, and B2.

This refinement highlights the atomic tasks, helping

to understand each step of the process. After the

completion of A2.2 and B2.2, there is a gateway that

checks if the tasks of the goal are completed so that

the next set of tasks can be performed, or the process

can be completed. For example, if task A2.2 is com-

pleted, the process moves on to B1.1; if not, it moves

back to A1.1.

Combining Goal and Process Models for the Specification of Human-Robot Collaborations

221

Human

Cobot

Human Goal

Cobot Goal

Start

End

Send Message

Receive message

Task

A1.1

Task

A1.2

Task

A2.1

Task

A2.2

Task

B1.1

Task

B1.2

Task

B2.1

Task

B2.2

Task

completed

No

Task

completed

No

yes

Yes

Figure 4: Refined BPMN.

4 EVALUATION

4.1 Case Example

We demonstrate how goal models and process models

can be combined to specify HRCA, using the semi-

automatic assembly of a toy truck as an example use

case.

The assembly process includes operations start-

ing from picking and preparing components to plac-

ing and screwing them. In the exemplary use case, a

toy truck is assembled through collaboration between

a human and a cobot. In the HRCA, the cobot initi-

ates by picking the truck’s load carrier from its storage

area and positioning it upside down on the collabora-

tive workspace. Subsequently, it proceeds to pick up

the cabin and chassis, placing each in the workspace.

The cobot then retrieves the front axle, securely hold-

ing it in place, and waits for the human operator to fix

it.

While the cobot handles these initial steps, the hu-

man operator prepares a sub-assembly by prepared

four axle holder by placing two screws in each. The

human operator then fixes the front axle with the pre-

pared axle holders with a screwdriver, and then re-

peats the process for the back axle.

4.2 Goal Model Creation

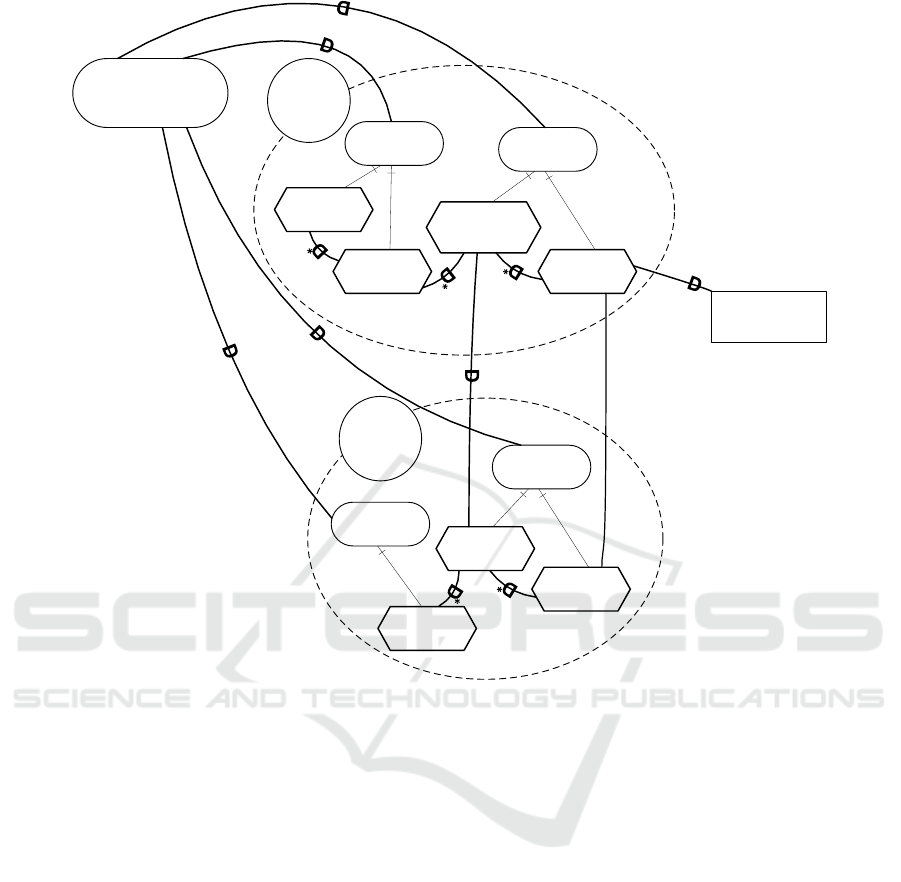

In the case of toy truck assembly, Figure 5 shows the

goal model for the example use case, outlining the co-

ordination between the human operator and the cobot.

This model highlights the main tasks required to as-

semble the truck and shows the dependencies between

these tasks. To achieve the main goal, the assembly of

the toy truck, and three sub-goals need to be fulfilled:

Prepare axle holders, prepare truck base and fix axles.

The two actors, human and cobot, have the fol-

lowing roles: Human: The human operator has two

primary tasks in the assembly process: preparing the

axle holders by picking and placing the parts and as-

semble them in the second step, and fixing the axles

with a screwdriver. These tasks depend on each other,

as picking and placing the parts is required for assem-

bling the axle holders, which are needed for the fixa-

tion of the axles.

Cobot: The cobot has two primary tasks: first,

preparing the truck base, and second, fixing the axles,

by first placing the axle and then holding the axles

in position, so the human operator can screw the axle

holders into place. The cobot tasks also have self-

dependencies, as the base of the truck needs to be as-

sembled, to place the axles.

The example also has two interdependencies be-

tween tasks of different actors. The first one is an

assembly sequence dependency, as the cobot has to

place the axle first, so that the human operator can put

the axle holders in place. The second one is a collab-

orative interaction, when the cobot holds the axle in

place and the human operation screws the parts to-

gether. This interdependent actions ensure that the

cobot’s tasks align with the human operator’s needs.

4.3 Deriving the BPMN from the Goal

Model

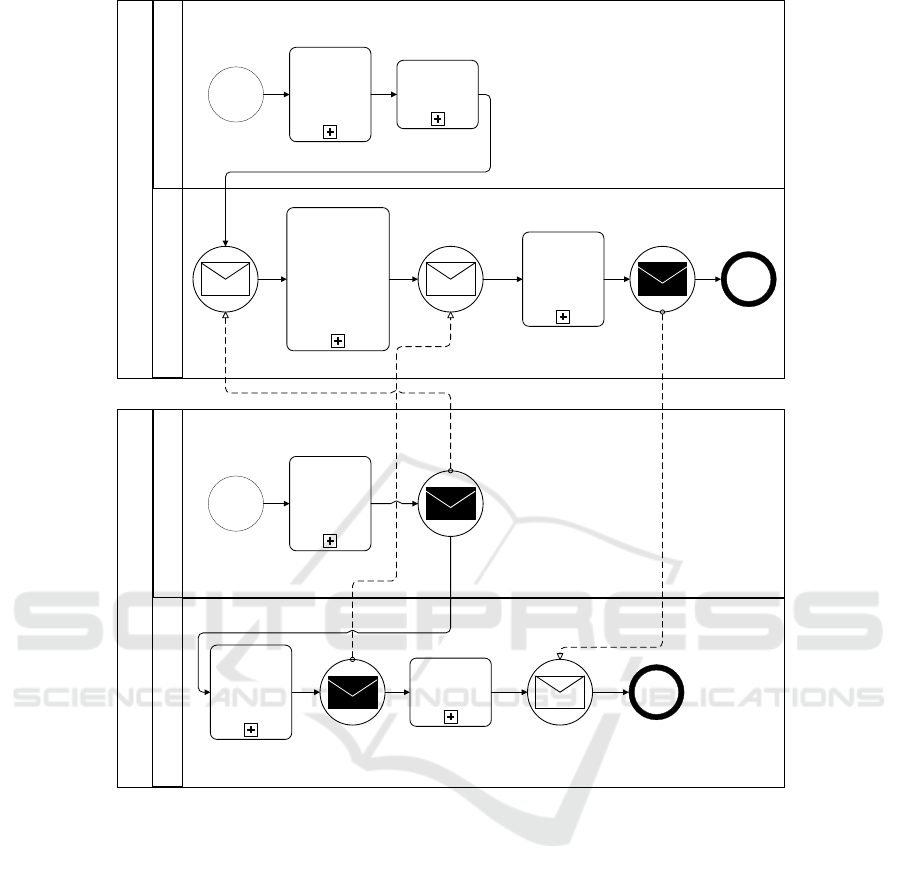

Based on the goal model and system specifications,

we derive a process model that outlines the tasks re-

quired for assembling the toy truck. This process

model, illustrated in Figure 6, depicts the tasks to be

undertaken by both the cobot and the human operator

throughout the assembly process.

The process model shows how the tasks are related

in terms of the overall assembly process (Figure 6).

ENASE 2025 - 20th International Conference on Evaluation of Novel Approaches to Software Engineering

222

Human

Cobot

Screw driver

Assemble toy truck

Prepare axle

holders

Pick and Place

parts

Assemble

parts

Fix axles

Screw parts

together

Pick and Place

assembled axle

holders

Prepare truck

base

Pick and Place

parts

Fix axles

Hold axle

Pick and Place

axles

D

D

AND

AND

AND

Figure 5: Goal model for the assembly of a toy truck.

Each actor (human operator and cobot) is repre-

sented as a BPMN pool, and their respective tasks

are captured as BPMN activities within these pools.

The tasks include the actions picking up components,

placing them in the workspace, and screwing the axles

into the truck body.

The main components of the BPMN are organized

as follows:

Cobot Pool: This pool contains tasks that the

cobot performs:

• “Pick and Place Parts”

• “Pick and Place Axles”

• “Hold Axles”

Human Operator Pool: This pool contains tasks

that the human operator performs:

• “Pick and Place Parts”

• “Assemble Parts”

• “Pick and Place Assembled Parts”

• “Screw Parts together”

In this phase, message events are used to represent

the interactions and dependencies between the two ac-

tors. For example, after the cobot places the axle, it

sends a message to the human operator, prompting

them to begin the next task of picking and placing

the axle holders. Similarly, after the human operator

finishes screwing, a message is sent back to the cobot,

instructing it to proceed with the next task.

4.4 Refining the BPMN

Figure 7 shows the refined BPMN which was ex-

tended from Figure 6.

Task Breakdown in BPMN: The process model

begins with the cobot executing a pick and place task,

in which it picks up the load carrier and positions it

within the collaborative workspace. The cobot then

proceeds to execute additional pick and place opera-

tions for the cabin and chassis.

When the cobot picks and places the front axle,

it holds the axle in position for the human operator

to perform the required assembly task of securing the

Combining Goal and Process Models for the Specification of Human-Robot Collaborations

223

Human

Prepare axle holders

Pick and

Place

parts

Assmble

parts

Hold

axles

Start

End

Send Message

Fix axles

Cobot

Prepare truck base

Pick and

Place

parts

Pick and

place

axles

Start

Fix axles

Pick and

Place

assemled

axle

holders

Screw

parts

together

End

Send Message

Send Message

Receive Message

Receive Message

Receive Message

Figure 6: BPMN derived from the goal model of the truck use case.

axle to the truck body. The cobot remains in this hold-

ing position until it receives a confirmation message

from the human operator indicating the completion

of the task. Upon receiving this message, the cobot

moves to the next instruction.

This task flow is repeated for the back axle.The

completion of the cobot’s tasks is signified by the

BPMN end notation, which indicates that all compo-

nents have been successfully assembled.

Human Operator Tasks in BPMN: The human

operator begins the assembly process by preparing the

axle holders for assembly. This involves picking the

axle holders, inserting screws into each slot, and ver-

ifying that all slots are filled.

In the next phase the human operator’s tasks, the

prepared axle holders for the front axle are placed

into position, with the cobot holding the axle in

place. This collaboration ensures that the axle hold-

ers are positioned accurately. Once the human oper-

ator confirms the correct placement, he proceeds to

use a screwdriver to secure the axle holders to the toy

truck’s body. After completing this task, the operator

confirms the execution and a message is sent to the

cobot to proceed with the next actions. This sequence

is then repeated for the back axle.

At the end of the process, the human operator en-

sures that all four axle holders are securely screwed

in place. This is represented by the gateway notation

in BPMN, indicating a decision point in the process.

If any axle holders are not correctly screwed in, the

human operator must repeat the screwing tasks until

all axle holders are correctly secured. Once all tasks

are completed, the process is complete.

Clarifying the Interaction Between Human and

Cobot: The BPMN provides clarity in illustrating the

separation of work between the human operator and

ENASE 2025 - 20th International Conference on Evaluation of Novel Approaches to Software Engineering

224

Human

Prepare axle holders

Start

End

Send Message

Fix axles

Cobot

Prepare truck base

Start

Send Message

Fix axles

End

Pick and Place 8

screws

Pick and Place 4

axle holders

Assemble axle

holders by

putting 2 screws

in one

Pick and Place

assembled axle

holder

Screw axle

holders to the

axles

Receive Message

Pick and Place

load carrier

Pick and Place

cabin

Pick and Place

chassis

Pick and Place 2

axles on the

front and back

of the chassis

Hold axle

Receive Message

Send Message

Receive Message

Yes

Axle holders

prepared

No

Screwed all

four axle

holders

Yes

No

Placed all

parts

Yes

No

Hold all four

axle holders

No

Yes

Figure 7: Refined BPMN of the truck use case.

the cobot, showing how their tasks are interdepen-

dent. BPMN also highlights the critical points where

human oversight and robotic precision intersect to en-

sure the assembly process is both efficient and ac-

curate. For instance: The human operator relies on

the cobot to position components accurately, such as

holding the axle in place during assembly. The cobot

waits for confirmation from the human operator be-

fore proceeding, ensuring that the tasks are coordi-

nated. This approach emphasizes the collaborative

nature of the task flow, ensuring that both the cobot

and human operator work together efficiently, with

clear roles and responsibilities throughout the assem-

bly process.

After the completion of every task in the process

lane, there are gateways that check if the tasks of the

human or cobot are complete in order to proceed with

the assembly process. For example, in the ’Prepare

Truck Base’ lane, after all the pick and place tasks,

the completion must be checked before sending the

message; if not, the process goes back to ’Pick and

Place Load Carrier.’

4.5 Discussion

The integration of goal models with BPMNs effec-

tively addresses the limitations of both approaches,

highlighting their complementary strengths and pro-

Combining Goal and Process Models for the Specification of Human-Robot Collaborations

225

viding a comprehensive framework for HRCA. As

demonstrated in the application example, goal mod-

els are excellent for identifying and emphasizing the

essential tasks required to achieve an overall objective

and how these tasks depend on each other. However,

goal models alone lack the sequential detail necessary

to fully understand how the tasks flow within a pro-

cess. This is where BPMN adds value by providing a

structured task flow and clearly delineating the order

of actions from start to finish.

The clear mapping between the GRL goal model

and the BPMN notations as shown in Figure 2 ensures

the compliance of the BPMN with the goal model and

offers several key benefits:

• Enhanced Clarity and Comprehension: The

combined use of goal models and BPMN provides

more detailed representation of the collaboration

process. While goal models focus on identifying

critical tasks, BPMN ensures the sequential flow

of actions is captured, making it easier to under-

stand how each task fits into the larger process and

how they interact.

• Improved Process Management: By integrating

the strategic focus of the goal model with the de-

tailed assembly sequence provided by the BPMN,

it becomes easier to manage and optimize HRCA.

This approach helps identify potential safety haz-

ards, areas for process improvement, and resource

allocation issues.

• Operational Efficiency: By leveraging the de-

tailed flow of the BPMN and the goal-oriented fo-

cus of the goal model, the integrated approach en-

ables the development of more efficient HRCA. It

ensures that the tasks of both the human operator

and cobot are aligned, well-coordinated.

• Comprehensive Documentation: The combined

approach ensures that both the high-level goals

and detailed process steps are thoroughly docu-

mented. This is essential not only for understand-

ing the HRCA, but also for process analysis, such

as evaluating efficiency and identifying areas for

continuous improvement.

In the present version, it is possible to derive a

BPMN from a goal model and then refine it accord-

ingly without affecting the mapping based on the

transformation table. This allows the creation of an

assembly sequence plan (BPMN) that is compliant

with the overall assembly objectives (goal model).

One limitation of this approach is that the soft

goals defined in the goal model are not translated

into the BPMN, which is mainly due to the fact that

the soft goals have a heterogeneous character. In the

context of the truck use case, a possible soft goal

of ‘safe interaction’ could be incorporated into the

BPMN as an event. Conversely, ‘efficient interaction’

would likely exert influence on the process flow of

the tasks. The implementation of a standardized no-

tation in these scenarios pose a significant challenge.

Nonetheless, it is imperative to acknowledge the im-

portance of soft goals in the context of HRCA.

5 CONCLUSION & FUTURE

WORK

HRC plays a crucial role in future manufacturing sce-

narios, where humans and robots collaborate on a

task-level to jointly create a product. This collabo-

ration enables semi-automation of flexible assembly

processes for small batch sizes or allows the imple-

mentation of complex assembly tasks that are chal-

lenging to fully automate. Therefore, careful plan-

ning and task allocation are essential to ensure ef-

fective collaboration. This is particularly important

during the early development stages, where analysis

must determine whether HRC can effectively solve a

particular task and identify critical aspects early on.

Recent works have demonstrated the utility of

goal models in supporting the early analysis of col-

laborative and robotic systems. Goal models are ex-

cellent at identifying high-level objectives, but they

often lack the sequential detail of the tasks required

to achieve those goals. Therefore, in this paper, we

introduced an integrated approach to derive process

models directly from goal models for HRCA. This

approach systematically transforms GRL-based goal

models into BPMN process models. It creates clear

traceability between high-level goals and detailed op-

erational tasks. We apply this approach to a toy truck

assembly use case. The results show improved task

specification, process clarity, and task coordination.

The integration of goal models and BPMNs align

strategic goals with workflows. This alignment sup-

ports better goal fulfillment, clearer task traceability,

and more efficient collaboration. It benefits semi-

automated manufacturing environments by enhancing

overall productivity and coordination. The abstract

nature of the transformation table makes it possible

for anyone to reuse the proposed integrated approach

by following it and therefore achieving the expected

outcomes.

In future work, we plan to extend this approach to

include safety assessments in HRCA. Safety is criti-

cal in environments where humans and robots work

closely together. Linking safety-related goals in goal

models to BPMN constructs allows for early hazard

detection. It also facilitates proactive safety monitor-

ENASE 2025 - 20th International Conference on Evaluation of Novel Approaches to Software Engineering

226

ing throughout workflows. Additionally, we will ex-

tend our case study to a larger-scale assembly setting

to demonstrate the scalability of our approach. We

plan to conduct a broader evaluation of the transfer-

ability from goal models to BPMNs in more complex,

industry-relevant scenarios, such as in the automotive

or aerospace industries, where task dependencies in

HRCA are more intricate. Finally, we plan to auto-

mate the overall framework using model-driven de-

velopment methods.

During the evaluation of our truck assembly, it

was realized that conclusions can be drawn not only

from the goal models to the BPMN, but also from the

refinement of the BPMN to a redesign of the goal

model. This creates a bidirectional iterative process

where both goal models and BPMN are continuously

improved. By expanding this methodology, we aim

to enhance the efficiency and effectiveness of HRCA,

ensuring that human operators and robots collaborate

more seamlessly to achieve the goals of modern man-

ufacturing.

REFERENCES

Amyot, D., Akhigbe, O., Baslyman, M., Ghanavati, S.,

Ghasemi, M., Hassine, J., Lessard, L., Mussbacher,

G., Shen, K., and Yu, E. (2022). Combining goal mod-

elling with business process modelling: Two decades

of experience with the user requirements notation

standard. Enterprise Modelling and Information Sys-

tems Architectures (EMISAJ), 17:2–1.

B

¨

ohm, B., B

¨

ohm, W., Daun, M., Hayward, A., Kranz, S.,

Regnat, N., Schr

¨

ock, S., Stierand, I., Vogelsang, A.,

Vollmar, J., Voss, S., Weyer, T., and Wortmann, A.

(2021). Engineering of collaborative embedded sys-

tems. In B

¨

ohm, W., Broy, M., Klein, C., Pohl, K.,

Rumpe, B., and Schr

¨

ock, S., editors, Model-Based En-

gineering of Collaborative Embedded Systems, pages

15–48. Springer.

Bourr, K., Corradini, F., Pettinari, S., Re, B., Rossi, L., and

Tiezzi, F. (2021). Disciplined use of bpmn for mission

modeling of multi-robot systems. In Working Confer-

ence on the Practice of Enterprise Modelling.

Chen, F., Sekiyama, K., Sasaki, H., Huang, J., Sun, B.,

and Fukuda, T. (2011). Assembly strategy modeling

and selection for human and robot coordinated cell as-

sembly. In 2011 IEEE/RSJ International Conference

on Intelligent Robots and Systems, pages 4670–4675.

IEEE.

Chen, P. (2007). Goal-oriented business process monitor-

ing. PhD thesis, Citeseer.

Cherubini, A., Passama, R., Crosnier, A., Lasnier, A.,

and Fraisse, P. (2016). Collaborative manufacturing

with physical human–robot interaction. Robotics and

Computer-Integrated Manufacturing, 40:1–13.

Corradini, F., Pettinari, S., Re, B., Rossi, L., and Tiezzi,

F. (2023). A bpmn-driven framework for multi-robot

system development. Robotics and Autonomous Sys-

tems, 160.

Daniel Amyot, O. A. (2022). Combining goal mod-

elling with business process modelling. Enter-

prise Modelling and Information Systems Architec-

tures (EMISAJ).

Daun, M., Manjunath, M., and Jesus Raja, J. (2023). Safety

analysis of human robot collaborations with grl goal

models. In International Conference on Conceptual

Modeling, pages 317–333. Springer.

Daun, M., Stenkova, V., Krajinski, L., Brings, J.,

Bandyszak, T., and Weyer, T. (2019). Goal model-

ing for collaborative groups of cyber-physical systems

with grl: reflections on applicability and limitations

based on two studies conducted in industry. In Pro-

ceedings of the 34th ACM/SIGAPP Symposium on Ap-

plied Computing, pages 1600–1609.

Est

´

evez, E. and Marcos, M. (2011). Model-based validation

of industrial control systems. IEEE Transactions on

Industrial Informatics, 8(2):302–310.

Fernandes, J., Reis, J., Mel

˜

ao, N., Teixeira, L., and Amorim,

M. (2021). The role of industry 4.0 and bpmn in the

arise of condition-based and predictive maintenance:

A case study in the automotive industry. Applied Sci-

ences, 11(8):3438.

Grau, A., Indri, M., Bello, L. L., and Sauter, T. (2020).

Robots in industry: The past, present, and future of a

growing collaboration with humans. IEEE Industrial

Electronics Magazine, 15(1):50–61.

Horkoff, J. and Yu, E. (2011). Analyzing goal models: dif-

ferent approaches and how to choose among them. In

Proceedings of the 2011 ACM Symposium on Applied

Computing, pages 675–682.

Jesus Raja, J., Manjunath, M., and Daun, M. (2024). To-

wards a goal-oriented approach for engineering digital

twins of robotic systems. In ENASE, pages 466–473.

Kem

´

eny, Z., V

´

ancza, J., Wang, L., and Wang, X. V.

(2021). Human–robot collaboration in manufacturing:

A multi-agent view. In Advanced human-robot collab-

oration in manufacturing, pages 3–41. Springer.

Kranz, P., Elbishbishy, S., Jesus Raja, J., and Daun, M.

(2024). Supporting safety assessment in human-

robot collaboration using process models. In ER2024:

Companion Proceedings of the 43rd International

Conference on Conceptual Modeling: ER Forum,

Special Topics,Posters and Demos, October 28-31,

2024, Pittsburgh, Pennsylvania, USA, pages 136–140.

CEUR Workshop Proceedings.

Lestingi, L. and Longoni, S. (2016). Hrc-team: A model-

driven approach to formal verification and deployment

of collaborative robotic applications.

Malik, A. A. and Bilberg, A. (2019). Developing a ref-

erence model for human–robot interaction. Interna-

tional Journal on Interactive Design and Manufactur-

ing (IJIDeM), 13(4):1541–1547.

Manjunath, M., Jesus Raja, J., and Daun, M. (2024). Early

model-based safety analysis for collaborative robotic

systems. IEEE Transactions on Automation Science

and Engineering.

Combining Goal and Process Models for the Specification of Human-Robot Collaborations

227

Matheson, E., Minto, R., Zampieri, E. G., Faccio, M.,

and Rosati, G. (2019). Human–robot collaboration

in manufacturing applications: A review. Robotics,

8(4):100.

Ortiz, J., Torres, V., and Valderas, P. (2024). Combin-

ing goal-oriented and bpmn modelling to support dis-

tributed microservice compositions. In ENASE, pages

75–86.

Ponsard, C. and Darimont, R. (2019). Towards goal-

oriented analysis and redesign of bpmn models. In

MODELSWARD, pages 527–533.

Sim

˜

oes, A. C., Pinto, A., Santos, J., Pinheiro, S., and

Romero, D. (2022). Designing human-robot collab-

oration (hrc) workspaces in industrial settings: A sys-

tematic literature review. Journal of Manufacturing

Systems, 62:28–43.

Van Lamsweerde, A. (2001). Goal-oriented requirements

engineering: A guided tour. In Proceedings fifth ieee

international symposium on requirements engineer-

ing, pages 249–262. IEEE.

Vysocky, A. and Novak, P. (2016). Human-robot collabora-

tion in industry. MM Science Journal, 9(2):903–906.

Wang, L., Liu, S., Liu, H., and Wang, X. V. (2020).

Overview of human-robot collaboration in manufac-

turing. In Proceedings of 5th International Confer-

ence on the Industry 4.0 Model for Advanced Manu-

facturing: AMP 2020, pages 15–58. Springer.

Weiss, A., Wortmeier, A.-K., and Kubicek, B. (2021).

Cobots in industry 4.0: A roadmap for future practice

studies on human–robot collaboration. IEEE Transac-

tions on Human-Machine Systems, 51(4):335–345.

ENASE 2025 - 20th International Conference on Evaluation of Novel Approaches to Software Engineering

228