Anomaly Detection Techniques in the Service of Data Labeling for Fault

Diagnosis in Manufaturing

Aldonso Martins de O. Junior

1,2 a

, Emmanuel A. de B. Santos

1 b

, Denis Leite

1,3 c

and Alexandre M. A. Maciel

3 d

1

Universidade de Pernambuco, Brazil

2

Stellantis, Brazil

3

Mekatronik I.C. Automacao Ltda, Brazil

aldonso.junior@stellantis.com, {emmanuel.andrade, alexandre.maciel}@upe.br, denis@mekatronik.com.br

Keywords:

Unsupervised Anomaly Detection, Anomaly Detection Models, Fault Identification, Fault Detection, Labeling

Process.

Abstract:

The lack of labeled fault data in industrial environments presents a major challenge for developing effec-

tive fault detection and diagnosis models. This study investigates the application of unsupervised anomaly

detection techniques to identify abnormal machine behavior without relying on labeled data. By enabling

the early detection of anomalous conditions, these techniques assist in distinguishing normal from faulty in-

stances, supporting the labeling process for improved fault diagnosis. Ten different techniques are evaluated

across multiple performance metrics to determine their effectiveness in industrial fault detection. Experimen-

tal results demonstrate that Angle-Based Outlier Detection (ABOD) outperformed other methods, achieving

a higher F1-score and improved accuracy in recognizing unseen normal data. These findings highlight the

potential of unsupervised learning for enhancing industrial fault detection, facilitating the transition to data-

driven maintenance strategies, and optimizing data collection processes. The study provides valuable insights

into model selection, dataset structuring, and cost-efficient implementation strategies for industrial applica-

tions, contributing to the broader adoption of anomaly detection in manufacturing environments.

1 INTRODUCTION

Industry 4.0 is transforming manufacturing and pro-

cess industries through digital technologies, automa-

tion, and data-driven approaches. This shift enhances

efficiency, flexibility, and intelligence in production,

supply chain, logistics, and maintenance. Key tech-

nologies such as machine learning, AI, and IoT drive

innovation, necessitating the alignment of machinery

and legacy systems with modern standards. To re-

main competitive, industries integrate these advance-

ments to optimize maintenance and improve opera-

tional performance (Ramesh et al., 2020; Dalenogare

et al., 2018; Ahmad and Kamaruddin, 2012; Zonta

et al., 2020; Tsui et al., 2015; Sakib and Wuest, 2018).

A critical challenge in adopting these technologies

for industrial fault detection is the lack of labeled data

a

https://orcid.org/0000-0001-6479-264X

b

https://orcid.org/0000-0002-1786-0934

c

https://orcid.org/0000-0002-0392-3279

d

https://orcid.org/0000-0003-4348-9291

in the early stages of digital transformation. In many

industrial environments, labeled fault data is scarce,

poor in quality, or non-existent, complicating the de-

velopment and training of traditional supervised ma-

chine learning models. This limitation hinders the

widespread adoption of intelligent fault detection sys-

tems, delaying improvements in operational reliabil-

ity and efficiency.

To address this issue, this study explores the use

of unsupervised anomaly detection techniques to dif-

ferentiate normal and anomalous machine behavior

without relying on labeled data. These techniques

enable industrial professionals to assess and classify

anomalies, refining fault detection and diagnosis pro-

cesses. By streamlining the labeling of abnormal con-

ditions, this approach enhances the development of

more accurate and robust fault detection models.

This study evaluates ten anomaly detection tech-

niques to identify the most effective models for in-

dustrial fault detection. Their performance is ana-

lyzed across multiple metrics to provide insights into

real-world applicability. The hypothesis posits that

O. Junior, A. M., Santos, E. A. B., Leite, D. and Maciel, A. M. A.

Anomaly Detection Techniques in the Service of Data Labeling for Fault Diagnosis in Manufaturing.

DOI: 10.5220/0013437100003929

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 27th International Conference on Enterprise Information Systems (ICEIS 2025) - Volume 1, pages 921-928

ISBN: 978-989-758-749-8; ISSN: 2184-4992

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

921

unsupervised techniques can detect faults using only

normal operational data, addressing the challenge of

scarce labeled datasets (Leite et al., 2025). To vali-

date this, a structured experimental approach is imple-

mented, assessing model performance under different

dataset configurations to highlight their strengths and

limitations in industrial applications.

2 MATERIALS AND METHODS

2.1 Data Sources and Collect

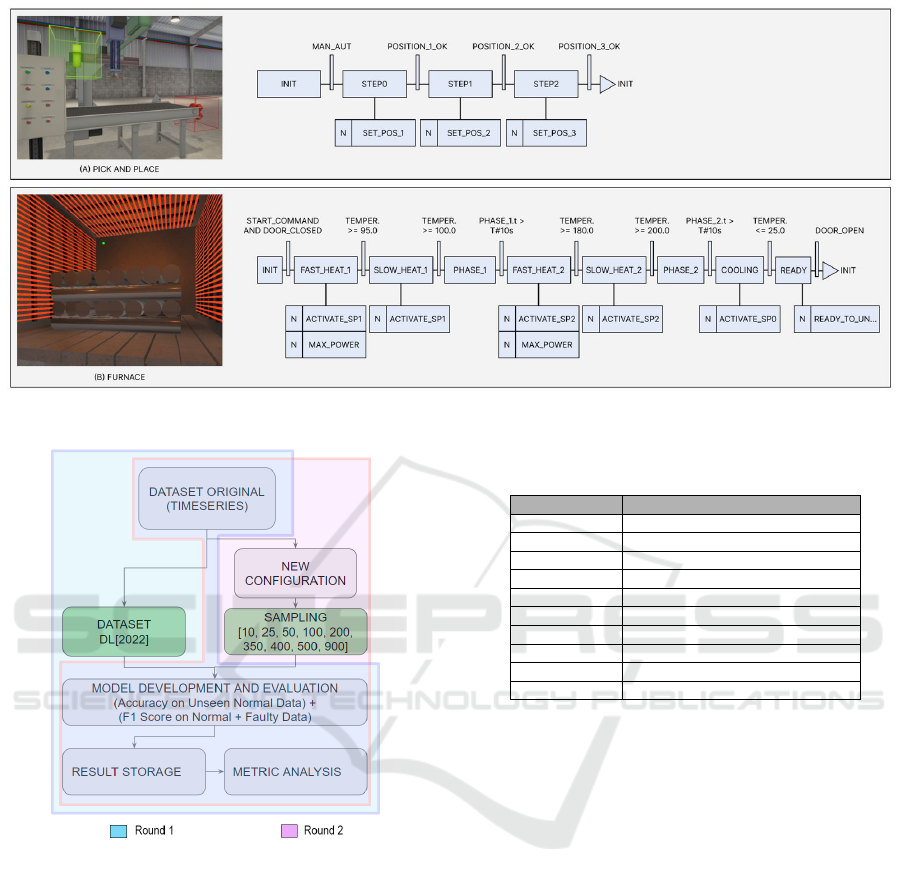

Due to the scarcity of real industrial production

datasets (Kang et al., 2020) and the lack of time series

data from Digital Manufacturing Machines (DMMs)

with both digital and analog IO signals (Leite et al.,

2022), simulated data was utilized. This approach,

was validated by Huang et al. (Huang et al., 2022)

for fault detection, and in this study contemplates two

simulators: a pick-and-place system and an electric

furnace (Figure 1). They were selected for their con-

trasting dynamic characteristics, providing distinct

profiles to test anomaly detection techniques in indus-

trial settings.

The simulations were run in Unity 3D, a game en-

gine with graphic and physics simulation capabilities.

The pick-and-place machine simulated motor forces,

friction, and loads, while the electric furnace imple-

mented a dynamic heating model and discrete simu-

lations for door conditions. Each simulated machine

was designed to reflect its operational characteristics

and potential failure conditions.

• Pick and Place Robot: Sequential machine with

linear movement system and short-time cycle.

Simulated forces, friction, and loads.

• Industrial Electric Oven: Thermal threatment sys-

tem, with slow heating and cooling process. Sim-

ulated heat transfer, resistance heating system,

and door conditions.

2.2 Data Detailing and Simulation

The Pick and Place machine simulation consists on

a 3-axis linear positioning system, which operates in

a sequential patten of three positions. Two types of

faults were simulated for each axis: punctual obstruc-

tions (emulating damages like linear guide or fuse

issues) and speed losses (representing motor driver

power loss, maladjustment, or increased friction).

And the corresponding dataset includes 308 normal

cycles operation and 103 cycles with each fault type,

and the simulation includes the following variables

for the Pick and Place system: target position of the

three axes, current position of the three axes (analog

data), forward and backward commands for the 3 axis.

The Furnace machine simulation features an elec-

tric heating system, a temperature sensor, and a door

mechanism. It comprises a thermal threating process

with heating and colling steps. For this simulation,

the following variables are considered: door open sig-

nal, door closed signal, heating turned on, maximum

power applied, temperature. And the corresponding

dataset includes 104 normal cycles and 104 cycles for

each fault condition, amounting to a total of 418 cy-

cles. Simulated faults are power loss at the heater,

thermal noise, and temperature spam error where in-

cluded.

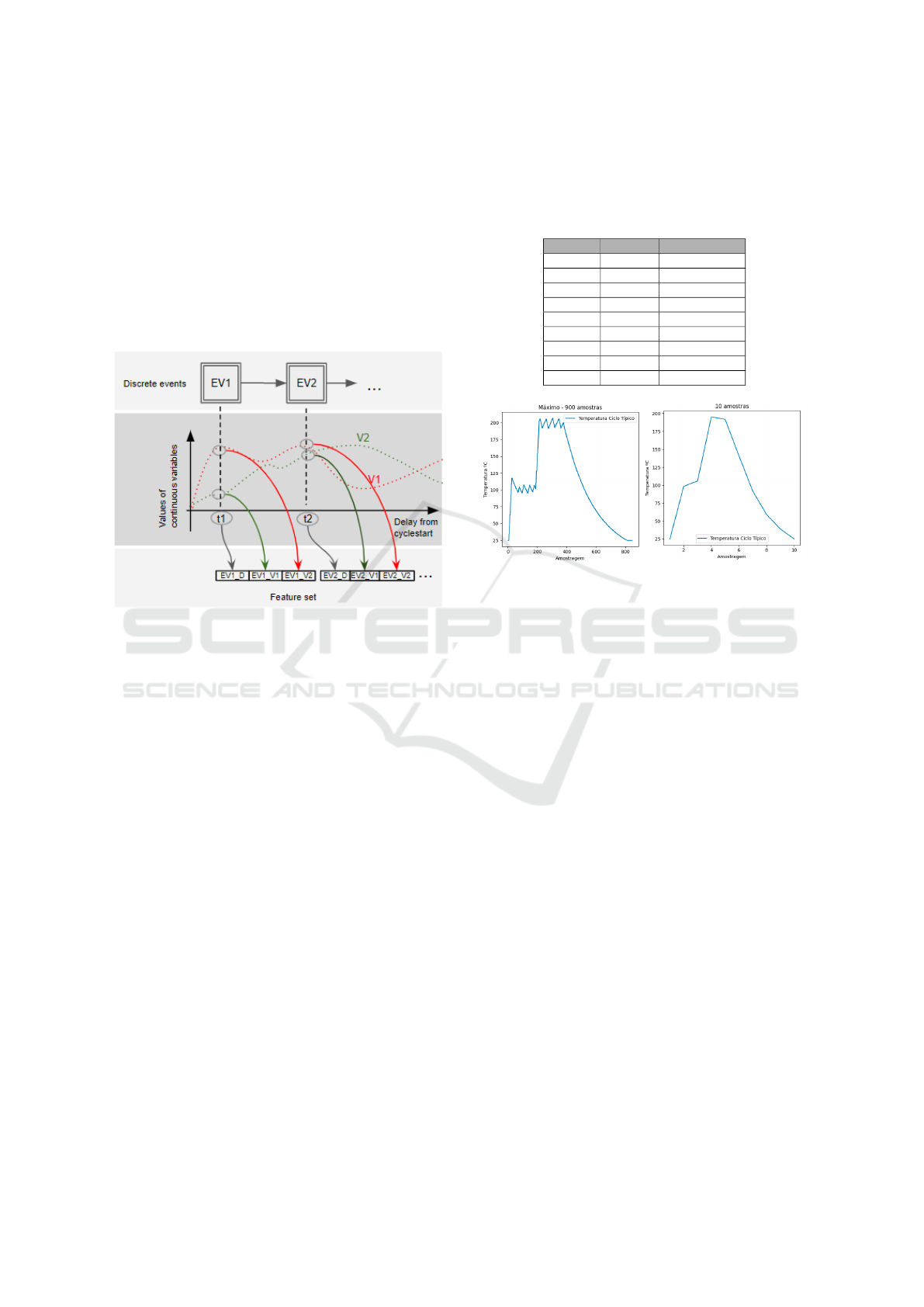

2.3 Methodological Structure

This research employs a methodological framework

designed to assess the effectiveness of anomaly de-

tection techniques in industrial fault detection. The

study is structured into two distinct rounds of exper-

iments, each addressing different aspects of anomaly

detection under varying conditions. This approach is

illustrated through two block diagrams, which offer a

macro perspective of both the experimental setup and

the detailed model development and evaluation pro-

cess.

• 1st Round: utilizes the same data organization as

employed by Leite et al. (2022)[8];

• 2nd Round: introduces a new dataset configura-

tion with a varying sampling rate per cycle.

Figure 2 presents the overall framework of the

study, beginning with the raw dataset and diverging

into two separate pathways for the respective exper-

imental rounds. Round 1 utilizes the dataset organi-

zation proposed by Denis et al. (2022) (Leite et al.,

2022), focusing on a custom mixed discrete and ana-

logical approach. In contrast, Round 2 delves into

a novel dataset configuration with varied sampling

number per cycle [10, 25, 50, 100, 200, 350, 400,

500, and 900]. This bifurcation allows for a multi-

faceted exploration of anomaly detection. Both paths

converge at the critical model development and eval-

uation process.

Ten different anomaly detection techniques were

selected to be exploited as lited in Table 1).

The dataset was divided into normal only dataset

and faulty dataset (to emulate the reality were the

data collection just started in a industry). The nor-

mal only dataset is then split in a 70-30 rate, creating

the train/test dataset, and the evaluation dataset (here

called unseen dataset). The train/test pass through 30

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

922

Figure 1: Furnace and Pick and Place Machines Cycle Detailed from Leite et al. (2022) (Leite et al., 2022).

Figure 2: Experimental Setup on Block Diagram with each

round conducted.

executions of a new split of 70-30 rate. This time the

70% portion is used to train each unsupervised learn-

ing method (Table 1) and the model is used to evaluate

it’s Accuracy, Recall and F1 Scoring against the test,

evaluation (unseen), faulty only and full datasets. All

results are recorded for a complete evaluation of the

experiments.

The PyCaret low-code library (Ali, 2020) played

a central role in the pre-processing and model devel-

opment process, significantly streamlining key tasks

such as feature scaling, train/test split management,

outlier removal, and feature selection. Incorporat-

ing Sklearn classifiers (Buitinck et al., 2013), Py-

Caret also facilitated the tuning and optimization of

anomaly detection models to achieve the best possi-

Table 1: All techniques used on Anomaly Detection Model

Creation.

Abbreviation Description

ABOD Angle-base Outlier Detection

CLUSTER Clustering-Based Local Outlier

COF Connectivity-Based Local Outlier

IFOREST Isolation Forest

HISTOGRAM Histogram-based Outlier Detection

KNN K-Nearest Neighbors Detector

LOF Local Outlier Factor

SVM One-class SVM Detector

PCA Principal Component Analysis

MCD Minimum Covariance Determinant

ble performance. The anomaly detection techniques

used in this study, listed in Table 1, were selected

based on literature reviews (Albuquerque Filho et al.,

2022). To ensure robustness, each technique was used

to generate 30 model variations with different random

states, mitigating biases from initialization and data

splits. Model evaluation followed a two-step process:

an initial assessment on test and unseen normal data to

measure accuracy in recognizing normal operations,

followed by testing on faulty data, where the F1 score

served as the primary metric due to the dataset’s un-

balanced nature.

As described, the models are trained exclusively

with normal data and evaluated on both normal, faulty

data and complete Dataset.

2.4 Dataset Preparation and

Experimental Details

Round 1 dataset preparation process followed Leite

et al. (2022). This approach, aims to capture the

machine behavior in a specific manner, requiring hu-

man contribution only in automation and maintenance

Anomaly Detection Techniques in the Service of Data Labeling for Fault Diagnosis in Manufaturing

923

domains, and no human contribution in the machine

learning domain.

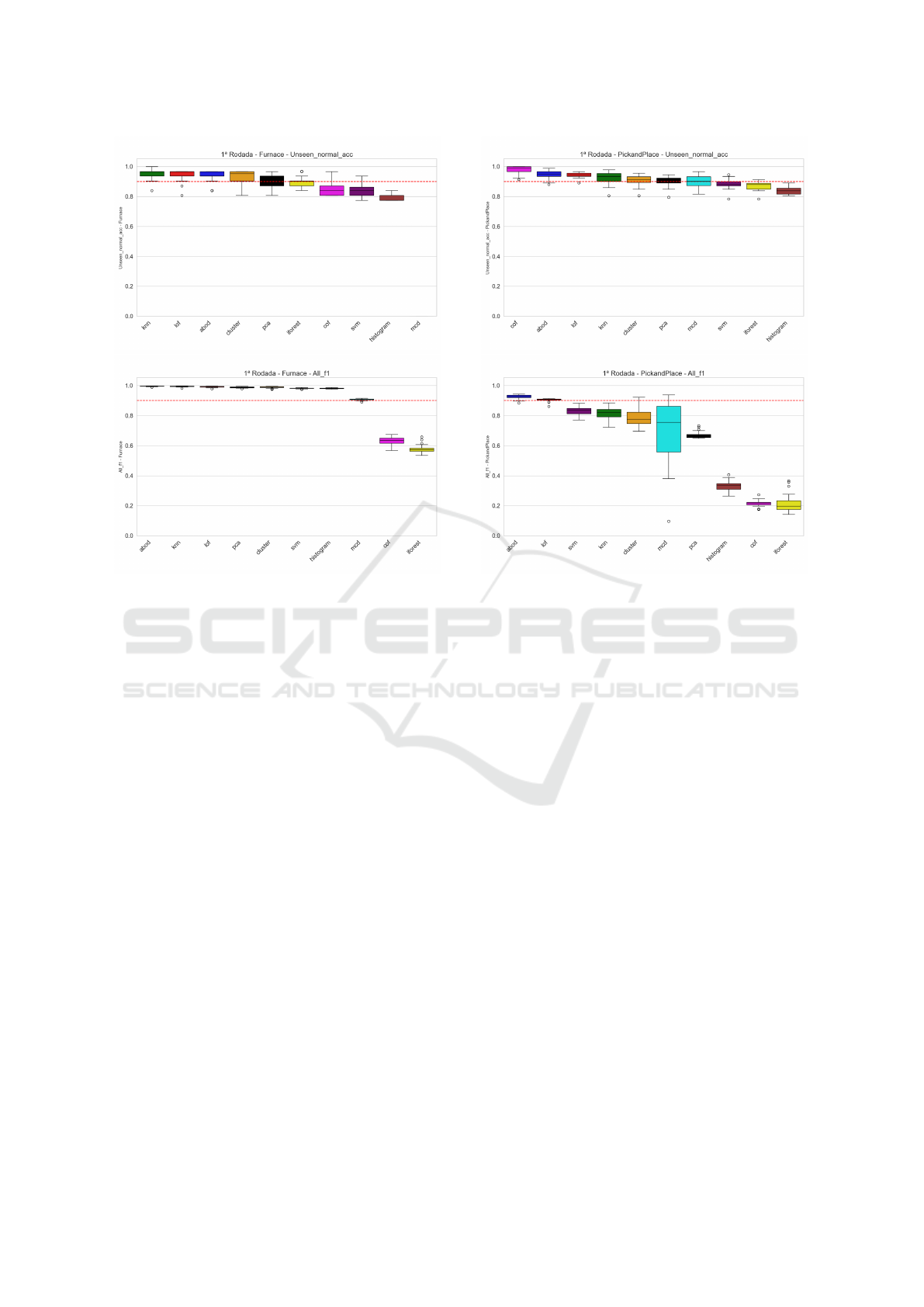

The outcome is a feature set that amalgamates

these discrete events with continuous variables, as

ilustrated in Figure 3, where each instance in the

dataset represents one machine cycle, filled with

timed delays of discrete events and the corresponding

values of continuous variables. This structure allows

for the detection of anomalies such as events occur-

ring out of order, delayed, or early, and issues with

calibration, utilities, or machine components:

Figure 3: Feature set preparation process combining dis-

crete events and continuous variables.

Round 2 embarked on a more abroad exploration

of anomaly detection capabilities by employing a dis-

tinct approach to data organization compared. While

both rounds focus on datasets that are cycle-oriented,

with each instance representing an entire machine

cycle, the key difference in Round 2 lies in a new

method of feature dataset definition. In this round, the

raw time-series data were restructured to capture sam-

ples of each variable at a fixed interval within each

cycle. This methodology requires less pre-processing

effort. However, depending on the number of samples

per cycle, it may incur a higher computational cost

and higher dimensionality, for the anomaly detection

models.

The expectation behind this schema was that a

more detailed data granularity would enable a more

accurate characterization of the machine’s behavior,

potentially leading to improved anomaly detection re-

sults compared to Round 1. To test this hypothesis,

the study examined how different number of samples

per cycle, representing a variety of operational scenar-

ios, would affect the performance of anomaly detec-

tion models. This involved creating various versions

of the dataset with different sampling intervals. Fig-

ure 4 shows an example of how the main variables

from the Furnace machine would look at different us-

ing 2 sampling rates.

Table 2: Different sample sizes for both experiments on

Round 2.

samples Furnace PickandPlace

10 X X

25 X X

50 X X

100 X X

200 X X

350 X

400 X

500 X

900 X

Figure 4: Illustration of feature temperature in Furnace with

2 differents sample sizes.

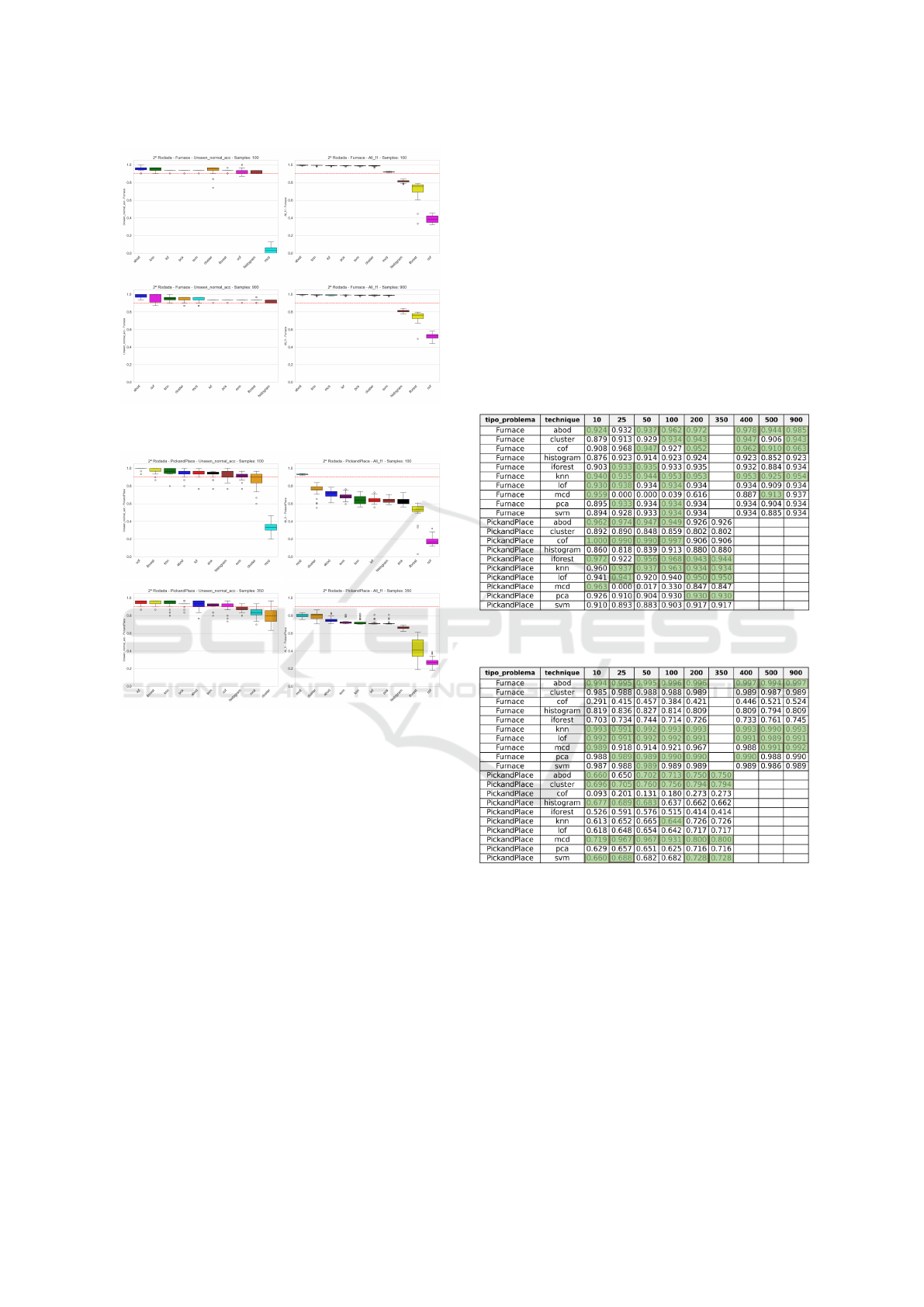

3 RESULTS

As outlined in the Materials and Methods section,

Round 1 involved applying 30 models across 10 se-

lected techniques for each simulated machine, total-

ing 600 experiments. In Round 2, 8 sampling vari-

ants were tested for the Furnace and 6 for the Pick-

and-Place machine, as detailed in Table 2, resulting

in 2400 models for the Furnace and 1800 for the

Pick-and-Place, bringing the total number of evalu-

ated Anomaly Detection (AD) models to 4800. This

section presents and discusses the results of both ex-

perimental rounds, as illustrated in Figure 2, focusing

on accuracy for unseen normal data and the F1 score

on the complete dataset (faulty + normal cases).

3.1 Round 1 - Analysis

The Figure 2 highlight the round 1 experiment from

which results are going to be discussed on this sec-

tion. The methodologies and evaluation metrics were

consistent with previous descriptions and methodol-

ogy.

The accuracy assessment on unseen normal (eval-

uation) data revealed commendable performance

across the anomaly detection techniques (see Figure

5 for details). When predicting both faulty and nor-

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

924

Figure 5: Results Accuracy on Unseen Normal Data + F1

Score on All Data - Furnace.

mal (all data set), the F1 score provided insights into

the overall effectiveness of the models. All of them

demonstrated robust performance (above 0.9 of F1)

except for COF and IFOREST which exhibited vary-

ing levels of effectiveness (see Figure 5 for details)

below 0.7.

The qualitative comparison emphasized the strong

performance of ABOD, KNN, LOF, PCA, CLUS-

TER, SVM, and histogram in terms of accuracy on

unseen normal data and F1 score on faulty plus nor-

mal data, demonstrating a high ability to distinguish

between normal and faulty conditions.

The same methodologies were applied to evalu-

ate anomaly detection techniques by extending the in-

vestigation to the pick-and-place machine. The accu-

racy of unseen normal data revealed distinct patterns

of performance for the pick-and-place machine.

When predicting both faulty and normal data,

ABOD, LOF, and SVM consistently outperformed

other techniques, effectively distinguishing between

normal and faulty conditions, whereas Histogram,

COF, and IFOREST exhibited lower effectiveness

(see Figure 6). Although COF achieved high accuracy

on unseen normal data for the Pick-and-Place ma-

chine, it failed to generalize for fault detection, show-

ing a significant drop in F1 score when faulty data was

introduced. In contrast, ABOD maintained strong

Figure 6: Results Accuracy on Unseen Normal Data + F1

Score on All Data - Pick and Place.

performance across both normal accuracy and F1

score, reinforcing its reliability. MCD exhibited un-

stable results, with noticeable variations in F1 scores,

while Histogram, COF, and IFOREST struggled with

fault identification. A holistic comparison between

the Furnace and Pick-and-Place experiments reveals

distinct patterns in anomaly detection performance,

with ABOD emerging as the most consistently effec-

tive technique across both systems, demonstrating its

versatility in different industrial contexts.

3.2 Round 2 Analysis

As a similar approach (but more diverse), the Figure 2

highlights the round 2 experiments and the it’s results

to be discussed on this section.

The experiments on the Furnace machine pro-

vided intriguing insights into the performance of

anomaly detection techniques across different sam-

ple sizes as show in Figure 7. Notably, as the sam-

ple size increased, there was a general trend of im-

provement in both Unseen Normal Accuracy and All

F1 Score. ABOD consistently secured a place in the

top four performers for Unseen Normal Accuracy in

seven out of eight experiments (see Table 5), show-

casing robustness across diverse sample sizes.

Anomaly Detection Techniques in the Service of Data Labeling for Fault Diagnosis in Manufaturing

925

Figure 7: Results for Furnace on different samples [100 and

900 columns].

Figure 8: Results for Pick and Place on different samples

[100 and 350 columns].

KNN and LOF also demonstrated notable con-

sistency and effectiveness in Furnace experiments,

maintaining high rankings across different sample

sizes. This reliability suggests that these techniques

might exhibit consistent performance in fault detec-

tion within the context of the Furnace machine.

Similar to the Furnace experiments, the Pick and

Place machine experiments displayed variations in

technique performance (Figure 8 with different sam-

ple sizes. ABOD, again, stood out by securing a place

in the top four for Unseen Normal Accuracy in four

out of six experiments (see Table 5), defying the antic-

ipated variability based on sample size. This consis-

tent performance underscores ABOD’s potential ap-

plicability in diverse industrial scenarios.

3.2.1 Round 2: Cross-Machine Comparison

The analysis of results from Round 2 experiments

across both the Furnace and Pick and Place machines,

as show in Tables 3 and 4 (in green are the best for

each group), has highlighted the remarkable and con-

sistent performance of ABOD. This is particularly

striking in the Furnace experiments, where ABOD’s

effectiveness was notably pronounced. Such findings

gain prominence considering ABOD’s absence in re-

cent literature reviews on anomaly detection in indus-

trial settings (Albuquerque Filho et al., 2022). This

oversight in the literature emphasizes the novelty of

our results, suggesting that ABOD may have unique

and previously unexplored capabilities for anomaly

detection in certain industrial environments.

Table 3: Results for Unseen Normal Accuracy (samples x

techniques x machines).

Table 4: Results for All Data F1 Score (samples x tech-

niques x machines).

Increasing the number of samples improved

model performance, but without significant changes,

suggesting that data collection does not need to oc-

cur every 50 ms (the maximum for certain OPC UA

hardware). A longer sampling interval can be used

without major impacts on results, reducing techno-

logical costs and investments in data acquisition soft-

ware. The consistent performance of ABOD, along

with the reliability of KNN and LOF in the Furnace

machine, highlights the complexity of anomaly detec-

tion effectiveness and the need for further exploration.

These findings, rarely addressed in recent literature,

provide valuable insights into fault detection method-

ologies in industrial settings. Notably, IFOREST and

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

926

COF performed poorly for both machines when ex-

posed to faulty data, reinforcing their limitations in

handling abnormal conditions.

Table 5: Summary of the number of times each technique

was in the top 4 for each machine regarding sample sizes

experiments.

4 DISCUSSION

The presented research embarked on a wide explo-

ration of anomaly detection techniques in the context

of fault detection for industrial machinery. Through

two rounds of investigation, the study examined dif-

ferent techniques across varying sample sizes and

two distinct machines: the Furnace and the Pick and

Place.

In both experimental rounds, models were initially

evaluated using only normal data, reflecting the typi-

cal scenario of a new industry implementing Indus-

try 4.0 capabilities. This allowed for selecting the

most suitable model before assessing its performance

in detecting real faults emulated through full dataset

exposure. The first round demonstrated the effec-

tiveness of various anomaly detection techniques in

identifying faults in the Furnace and Pick-and-Place

machines. ABOD consistently achieved high Unseen

Normal Accuracy across different sample sizes, chal-

lenging the assumption that technique effectiveness is

highly dependent on sample size. Additionally, KNN

and LOF proved to be reliable performers in the Fur-

nace machine, reinforcing their potential for robust

fault detection.

The second round further explored the impact of

sample size on anomaly detection. ABOD contin-

ued to deliver stable results across both machines, re-

inforcing its versatility and questioning conventional

assumptions about sample size reliability. A key fac-

tor in ABOD’s success is its reduced susceptibility to

the curse of dimensionality, as noted by Kriegel et al.

(Kriegel et al., 2008). By analyzing the variance of

angles between data vectors, ABOD effectively iden-

tifies outliers, making it a promising candidate for

industrial fault detection. This distinctive approach

warrants further investigation, potentially paving the

way for advancements in anomaly detection method-

ologies.

This study opens avenues for future investigations,

encouraging researchers and practitioners to explore

anomaly detection techniques beyond conventional

expectations, particularly in scenarios with varying

sample sizes. Additionally, it highlights the intricate

relationship between sample sizes, machine types,

and anomaly detection methods (as shown in Tables

3 and 4). These findings emphasize the need for a nu-

anced approach where technique selection is guided

by established practices and empirical observations

tailored to the specific industrial context. Naturally,

despite efforts to model and incorporate real-world

randomness, studies based on simulated data have in-

herent limitations. Therefore, future work should ex-

plore these techniques using real-world data to further

validate and refine the findings.

Furthermore, no comparison with other studies

was performed due to the scarcity of benchmark

datasets from industrial manufacturing machines,

which a key challenges on establishing the state of

the art in this fault diagnosis field(Leite et al., 2025),

Therefore, new studies may benefit from investigat-

ing new techniques over the same dataset used in this

study by contacting the authors.

5 CONCLUSIONS

The outcomes of this study significantly address the

predicament of limited labeled data in the discrete

manufacturing industry. By exploring ten differ-

ent anomaly detection techniques, trained exclusively

with normal data, we have quantified their effective-

ness in distinguishing normal from faulty conditions.

The results show that the Angle-Based Outlier Detec-

tion (ABOD) technique achieved an average increase

in F1-score compared to other methods, demonstrat-

ing its suitability for real-world applications in fault

detection.

One of the most prominent findings is the ef-

fectiveness of ABOD in handling manufacturing

data, where it consistently outperformed other mod-

els. This insight is particularly valuable for re-

searchers and professionals seeking robust and scal-

able anomaly detection methods for industrial ma-

chinery.

The comparative analysis between the two dataset

configurations led to a surprising conclusion: the less

detailed approach from previous work proved more

effective in fault detection than the more comprehen-

sive setup. This finding highlights that the quality and

relevance of data are often more critical than sheer

Anomaly Detection Techniques in the Service of Data Labeling for Fault Diagnosis in Manufaturing

927

quantity when constructing training sets for anomaly

detection models.

Ultimately, this research contributes insights to

the field of fault detection in industrial systems, chal-

lenging conventional notions and paving the way

for more nuanced and effective anomaly detection

methodologies. The findings encourage a shift to-

ward a more adaptive and context-aware approach in

implementing anomaly detection techniques for di-

verse industrial applications. These insights provide

a strong foundation for future studies aimed at refin-

ing anomaly detection strategies and validating them

in real-world manufacturing settings.

ACKNOWLEDGEMENTS

The authors would like to thank the research team

GPCDA (Grupo de Pesquisa em Ci

ˆ

encia de Dados e

Analytics) at PPGEC-UPE for all the invaluable con-

tributions to the discussions and for their support. We

need also to thank the huge contribution of Meka-

tronik’s Team for sharing the simulation data and for

the opportunity to work on methodology and exper-

iment execution. And to thank Stellantis Goiana for

all the support and incentive. Gratitude is extended to

CAPES and CNPq for their financial support, without

which this work would not have been possible.

This paper was financed in part by the

Coordenac¸

˜

ao de Aperfeic¸oamento de Pessoal de

N

´

ıvel Superior - Brazil (CAPES) - Finance Code

001, Fundac¸

˜

ao de Amparo a Ci

ˆ

encia e Tecnologia do

Estado de Pernambuco (FACEPE), the Conselho Na-

cional de Desenvolvimento Cient

´

ıfico e Tecnol

´

ogico

(CNPq) - Brazilian research agencies.

REFERENCES

Ahmad, R. and Kamaruddin, S. (2012). An overview of

time-based and condition-based maintenance in in-

dustrial application. Computers &industrial engineer-

ing.

Albuquerque Filho, J. E. D., Brand

˜

ao, L. C. P., Fernandes,

B. J. T., and Maciel, A. M. A. (2022). A review of

neural networks for anomaly detection. IEEE Access,

10:112342–112367.

Ali, M. (2020). PyCaret: An open source, low-code ma-

chine learning library in Python. PyCaret version 2.3.

Buitinck, L., Louppe, G., Blondel, M., Pedregosa, F.,

Mueller, A., Grisel, O., Niculae, V., Prettenhofer, P.,

Gramfort, A., Grobler, J., Layton, R., VanderPlas, J.,

Joly, A., Holt, B., and Varoquaux, G. (2013). API de-

sign for machine learning software: experiences from

the scikit-learn project. In ECML PKDD Workshop:

Languages for Data Mining and Machine Learning,

pages 108–122.

Dalenogare, L., Benitez, G., Ayala, N., and ... (2018). The

expected contribution of industry 4.0 technologies for

industrial performance. International Journal of . . . .

Huang, J., Wen, J., Yoon, H., Pradhan, O., Wu, T., and

Neill, Z. O. (2022). Energy & Buildings Real vs

. simulated : Questions on the capability of simu-

lated datasets on building fault detection for energy

efficiency from a data-driven perspective. Energy &

Buildings, 259:111872.

Kang, Z., Catal, C., and Tekinerdogan, B. (2020). Machine

learning applications in production lines : A system-

atic literature review. Computers & Industrial Engi-

neering, 149(August):106773.

Kriegel, H., Schubert, M., and Zimek, A. (2008). Angle-

based outlier detection in high-dimensional data. Pro-

ceedings of the 14th ACM . . . .

Leite, D., Andrade, E., Rativa, D., and Maciel, A. M.

(2025). Fault Detection and Diagnosis in Industry 4.0:

A Review on Challenges and Opportunities. Sensors,

25(1):1–34.

Leite, D., Martins, A. J., Rativa, D., Oliveira, J. D., and

Maciel, A. (2022). An automated machine learning

approach for real-time fault detection and diagnosis.

Sensors.

Ramesh, P., Dutta, S., Neog, S., Baishya, P., and ... (2020).

Implementation of predictive maintenance systems in

remotely located process plants under industry 4.0

scenario. . . . Engineering: In Honor of . . . .

Sakib, N. and Wuest, T. (2018). Challenges and opportuni-

ties of condition-based predictive maintenance: a re-

view. Procedia cirp.

Tsui, K., Chen, N., Zhou, Q., Hai, Y., and Wang, W. (2015).

Prognostics and health management: A review on data

driven approaches. Mathematical Problems in . . . .

Zonta, T., Costa, C. D., da Rosa Righi, R., and ... (2020).

Predictive maintenance in the industry 4.0: A system-

atic literature review. Computers &Industrial . . . .

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

928