Transforming Systems Engineering in Nuclear Projects with

Generative AI: A Path to Efficiency and Compliance

Jérémy Bourdon

a

, Julien Rodriguez, Quentin Lesigne, Pauline Suchet, Berenger Fister,

Loic Montagne, Olivier Malhomme, Lies Benmiloud-Bechet and Robert Plana

b

Assystem Energy and Operation Services (AEOS), Tour Egée, Courbevoie 92400, France

Keywords: Systems-Engineering, LLM, SysML, Requirements Extraction, Requirements Allocation,

Engineering Automation.

Abstract: This article explores the integration of generative artificial intelligence (AI) into nuclear systems engineering

to improve efficiency and compliance. The Generative Systems Engineering (GenSE) project is transforming

traditional systems engineering processes by leveraging AI across the entire plant lifecycle. Key challenges

addressed include the extraction and reformulation of requirements, their allocation within the Product

Breakdown Structure (PBS), and integration with existing engineering tools. To meet these challenges, a

specialized Large Language Model (LLM) tailored for Nuclear Engineering, named "CurieLM", has been

developed through fine-tuning. A workflow has been developed, using CurieLM, to automate requirements

extraction, ensure quality assurance according to INCOSE guidelines, and facilitate allocation while

maintaining compliance with ISO 15288 and ISO 24641 and integrating with SysML tools. The case study

on a MOX fuel fabrication plant shows significant time reductions: 88% in requirements extraction, 87% in

reformulation, and 66% in allocation to PBS. These improvements are accompanied by a gain in quality,

based on feedback from requirements engineers. However, human verification remains essential to interpret

and validate the results. In conclusion, the article highlights the potential of AI to transform systems

engineering, while highlighting the need for collaboration between humans and AI to guarantee the quality of

decisions.

1 INTRODUCTION

Over the past two years, Energy Transition policies

have undergone significant shifts, with nuclear

energy emerging as a cornerstone for achieving CO2

reduction targets. This shift has led to the initiation of

numerous nuclear programs, bringing new challenges

related to the timely and cost-effective delivery of

these projects. Similar issues were encountered in the

aerospace and aeronautics sectors years ago and were

effectively addressed through the adoption of

Systems Engineering.

However, in the nuclear sector, engineering

practices remain predominantly document-centric,

posing a significant barrier to improving project

delivery timelines and overall performance. This

underscores the urgent need for research aimed at

automating, simplifying, and accelerating the

a

https://orcid.org/0000-0001-6475-044X

b

https://orcid.org/0000-0003-2378-8331

adoption of system modeling approaches in nuclear

infrastructure projects. The Generative Systems

Engineering (GenSE) project aims to redefine

systems engineering processes for installations

throughout their lifecycle, by integrating artificial

intelligence (AI) and more specifically foundation

models. In addition, it would support operations,

safety considerations and compliance with

requirements.

However, integrating AI into nuclear systems

engineering raises several challenges. Both technical

and practical problematics need to be resolved to

ensure effective implementation.

One concern is the accuracy and completeness of

the probabilistic results generated by AI, particularly

regarding needs and requirements analysis, functional

and physical modeling, and system validation. It is

essential to use carefully constructed data sets,

Bourdon, J., Rodriguez, J., Lesigne, Q., Suchet, P., Fister, B., Montagne, L., Malhomme, O., Benmiloud-Bechet, L. and Plana, R.

Transforming Systems Engineering in Nuclear Projects with Generative AI: A Path to Efficiency and Compliance.

DOI: 10.5220/0013443400003896

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 13th International Conference on Model-Based Software and Systems Engineering (MODELSWARD 2025), pages 395-406

ISBN: 978-989-758-729-0; ISSN: 2184-4348

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

395

include deterministic post-treatments and always

keep human in the loop to minimize the risk of errors

or omissions. In a field as critical as nuclear energy,

even small inaccuracies can have significant

repercussions on Nuclear Safety throughout the

lifecycle.

Another obstacle lies in the integration of AI tools

within existing engineering tools. These tools need to

fit into established workflows and platforms, to

encourage their adoption. They also need to

demonstrate their ability to enhance process

efficiency without introducing unnecessary

complexity. The main objective is to enhance

engineers' capabilities while preserving the continuity

of existing practices.

User confidence is an essential element. For these

tools to be adopted, engineers must perceive them as

useful and adapted to their needs. This means

involving them during the tool development phases,

so that their feedback integrates the proposed

solutions. The tools must also bring concrete benefits

to operational tasks, reinforcing their status as useful

tools rather than mere innovation fads.

By addressing these challenges, the GenSE

project aims to modernize nuclear systems

engineering practices. It relies on AI to improve

decision-making, optimize processes and increase the

efficiency and reliability of engineering tasks. At the

same time, it offers solutions tailored to the specific

needs of the nuclear sector.

2 BACKGROUND

2.1 Context

The GenSE initiative is taking place against a

backdrop of increasing demands to improve the safety

and regulatory compliance of critical infrastructures,

particularly in the nuclear industry. The increasing

complexity of the design and management of these

facilities stems from stringent legal frameworks and

the imperative of safe and efficient operation. These

technical and regulatory challenges are further

exacerbated by economic constraints to optimize

costs, streamline processes and maintain rigorous

quality and safety standards.

Economic considerations in the nuclear sector are

various. One of the main challenges is the constant

need to reduce costs, not only during the construction

of new facilities, but also during the operation and

eventual decommissioning of existing ones. At the

same time, it is essential to accelerate the pace of

design processes, as the regulatory constraints and

complexity of nuclear projects often lead to long and

costly development cycles. In addition, maintaining

the reliability and safety of nuclear systems remains a

mandatory requirement. The Nuclear Safety

requirements of such facilities requires robust

engineering practices and traceability to ensure safe

and reliable operations.

The GenSE aims to tackle these challenges by

developing AI-driven tools to improve systems

engineering methodologies. By integrating artificial

intelligence into engineering workflows, the project

seeks to optimize processes, reduce costs, improve

quality and the global efficiency of project execution.

This approach also contributes the design phases to

be completed on schedule as safety and compliance

standards are met. Thanks to these innovations, the

GenSE initiative intends to provide the nuclear

industry with a framework that enables it to overcome

its technical and economic hurdles, while preserving

the integrity and reliability of its critical

infrastructure.

2.2 State of the Art

This section presents a review of the literature on Text

to model approaches to SysML generation, focusing

on the nuclear domain. It addresses key issues

concerning recent advances, methodologies and

challenges in this field.

The use of Optical Character Recognition (OCR)

and Natural Language Processing (NLP) for

automatic requirements extraction from numeric and

printed text documents is an active area of research.

(Ben Nasr, 2016; Luttmer et al., 2023; Patel et al.,

2024; van Remmen et al., 2023). Language models,

pre-trained on large datasets, can be refined for

specific technical domains such as nuclear

engineering. Rule-based, machine learning and deep

learning approaches are used to identify and classify

requirements (Akundi et al., 2024; Luttmer et al.,

2023; Zhao et al., 2022). The integration of domain-

specific knowledge, such as ontologies and nuclear

glossaries, can improve the accuracy of requirements

extraction (Ben Nasr, 2016; Cocci et al., 2024) For

example, CurieLM, a refined language model for the

nuclear domain, illustrates the integration of specific

knowledge to improve understanding of nuclear texts

(Bouhoun et al., 2024).

Despite progress, the automatic generation of

SysML models from text still faces a number of

limitations (Ahmad et al., 2022; van Remmen et al.,

2023). The ambiguity of natural language, the

complexity of nuclear systems and the lack of

structured training data are major obstacles (Chami et

MBSE-AI Integration 2025 - 2nd Workshop on Model-based System Engineering and Artificial Intelligence

396

al., 2019; Luttmer et al., 2023; Necula et al., 2024).

Interface management, requirements allocation and

change impact analysis are particularly difficult to

automate (Ahmad et al., 2022; Cocci et al., 2024;

McDermott et al., 2020).

Artificial intelligence (AI) and machine learning

(ML) offer opportunities to improve the accuracy and

completeness of automatically generated models

(Cocci et al., 2024; McDermott et al., 2020; Zhang &

Yang, 2024). Techniques such as reinforcement

learning, transfer learning and deep neural networks

can be used to optimize model structure, semantics

and consistency (Akundi et al., 2024; Winkler &

Vogelsang, 2017). The integration of automatic

model validation and human feedback can further

refine the generation process. This extract about the

Large Language Model (LLM) "The LLM

meticulously examines these architectures and

evaluates their alignment with the defined

requirements. By correlating the intricate details

within the physical and functional architectures, the

LLM verifies if they meet or deviate from the

established requirements." (Cocci et al., 2024)

describes how a language model can be used to check

the conformity of system architectures with

requirements.

The integration of domain-specific knowledge is

essential for the generation of accurate and relevant

SysML models for nuclear engineering. (Ben Nasr,

2016; Bouhoun et al., 2024; Zhang & Yang, 2024).

Nuclear ontologies, technical lexicons and

component databases can provide valuable context

for modeling algorithms (Alaoui et al., 2023).

Knowledge extraction techniques from existing

documents and models can also be used.

Compliance verification is crucial to ensure that

nuclear systems comply with safety standards and

regulations. The integration of compliance rules,

constraints and standards into the text-model system

enables real-time verification during the modeling

process (Cocci et al., 2024). Formal logic and model

checking techniques can be used to automate the

verification process (Ben Nasr, 2016; Luttmer et al.,

2023).

Managing interfaces and allocating requirements

in complex systems is a major challenge for

automation (Ahmad et al., 2022; McDermott et al.,

2020). The complexity of interactions between

components, the evolution of requirements and the

lack of clear traceability make it difficult to capture

these relationships automatically (van Remmen et al.,

2023). Approaches based on knowledge graphs,

semantic analysis and machine learning are being

explored to tackle these challenges (Petnga, 2019).

Change impact analysis is essential for assessing

the consequences of design or requirement

modifications on the overall system (Mengist et al.,

2021). Integrating this analysis into text-model

systems makes it possible to track dependencies

between model elements and predict the potential

impact of changes (Weston et al., 2009). Constraint

propagation, dependency analysis and simulation

techniques can be used to automate this process

(Plehn, 2018).

Automatic SysML (OMG, 2006) and diagrams

from documentation is an important objective for

improving communication and understanding of

systems (Patel et al., 2024)Model transformation,

natural language generation and graphical

visualization techniques are used to produce clear,

concise and informative documents (Akundi et al.,

2024)

Evaluating the quality and accuracy of

automatically generated models is essential to

guarantee their reliability and usefulness (Chapurlat,

2013). Measures such as precision, recall,

requirements coverage and semantic consistency can

be used to quantify model quality. Techniques such

as expert validation, comparison with reference

models and simulation testing can complement these

measures (Nastov et al., 2015).

The integration of text-model systems for SysML

generation in the nuclear domain promises to improve

the efficiency, accuracy and traceability of the system

design process. Although significant progress has

been made, challenges remain in terms of natural

language ambiguity, managing system complexity

and integrating domain-specific knowledge. Future

research should focus on developing more robust

NLP techniques, more intelligent AI models and

more rigorous evaluation methods to overcome these

limitations and realize the full potential of text-model

systems for SysML generation in the nuclear domain.

3 METHODOLOGY

The GenSE concept is structured around eleven

themes. These themes cover current activities in

systems engineering and focus on preliminary design.

These themes are derived below :

Automated Requirements Extraction:

Automating the extraction of requirements

from documented requirements

specifications.

Requirements Quality: Reformulate

requirements to comply with best practices

such as INCOSE.

Transforming Systems Engineering in Nuclear Projects with Generative AI: A Path to Efficiency and Compliance

397

Functional Architectures: Automate the

creation of alternative functional

architectures in response to requirements.

Work Breakdown Structure: Automate the

creation of a work breakdown structure for a

design project.

Product Breakdown Structure and

Architectures: Automate the creation of

logical architecture alternatives consistent

with a functional architecture, and physical

architecture alternatives consistent with a

logical architecture.

Requirement Allocation: Automate the

allocation of requirements to different

engineering artifacts.

Project Interfaces: Automate the

identification and documentation of

interfaces in WBS elements, consistent with

the organic architecture.

Continuous Verification of Compliance:

Automate the verification of compliance with

the requirements of the system as designed,

aiming for continuous verification.

Layout: Generate installation layout

alternatives with the various zoning zones

common in the nuclear sector (e.g.

radiological, fire, safety, etc.).

Deliverable Production: Automate the

creation of deliverables based on stakeholder

expectations and all documentation

developed (templates and documents).

Change Impact: Automate the analysis and

prediction of the impact on the design of a

change (e.g. requirements, functionalities,

configurations, etc ).

In the remainder of this article, we will detail a

workflow that integrates three of these themes:

automated extraction, requirements quality and

allocation. This workflow is intended to support the

stakeholder and systems requirements definition

process as described in ISO 15288 (ISO & IEC,

2023a) and ISO 24641 (ISO & IEC, 2023b).

4 ASSIST STAKEHOLDERS AND

SYSTEM REQUIREMENTS

DEFINITION PROCESSES

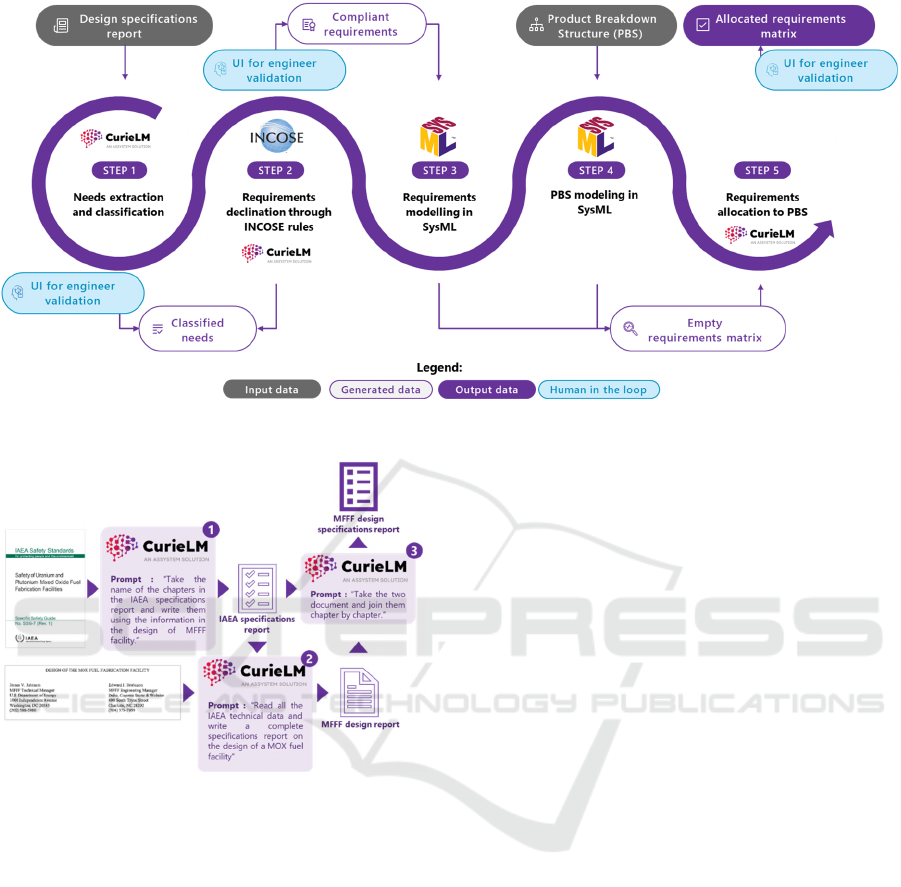

The workflow architecture is illustrated in Figure 1,

which shows the input data in gray (i.e. a PBS-type

specification and decomposition of the system of

interest), the data produced by generative AI in

purple, and the human interaction in blue. The tools

used in this architecture include CurieLM-Mistral-

7B-Instruct-v0.2, tools implementing the SysML

language and INCOSE rules. In addition, a human-

machine interaction (HMI) interface has been

developed. The CurieLM-Mistral-7B-Instruct-v0.2

model, hereafter referred to as the CurieLM model, is

a fine-tuned model based on the Mistral 7B Instruct

v0.2 model, using instructions and data specific to the

nuclear sector (Bouhoun et al., 2024).

For this workflow, we will apply the experiments

to a case study of a Mixed Oxide Fuel (MOX)

fabrication plant. This plant is designed to produce

nuclear fuel from mixed fissile materials.

The input data to be collected must be sufficient

for the system of interest, the system whose life cycle

is under consideration, and must also be public. We

based our research on open-access documents

describing an existing Mox Fuel Fabrication Facility

(MFFF). The choice of this system allows us to obtain

technical data close to current design projects for a

MOX fabrication facility in France. To describe this

system, a list of documents was made available to the

workflow:

Design of the MOX fuel fabrication facility

(Johnson & Brabazon, 1993)

Application for authorization to construct

the MOX fuel fabrication facility (DCS,

2006)

To consolidate the technical information

retrieved, we relied on the following IAEA

documents:

AIEA, Status and advance in MOX

technology (INTERNATIONAL ATOMIC

ENERGY AGENCY, 2003)

AEIA, SSG7 Safety of Uranium and

Plutonium Mixed Oxide Fuel Fabrication

Facilities (INTERNATIONAL ATOMIC

ENERGY AGENCY, 2023a)

AIEA, SSG6 Safety of Uranium fuel

fabrication facilities (INTERNATIONAL

ATOMIC ENERGY AGENCY, 2023b)

4.1.1 Step 1: Needs Extraction and

Classification

The first Sub-step is to create a design specification

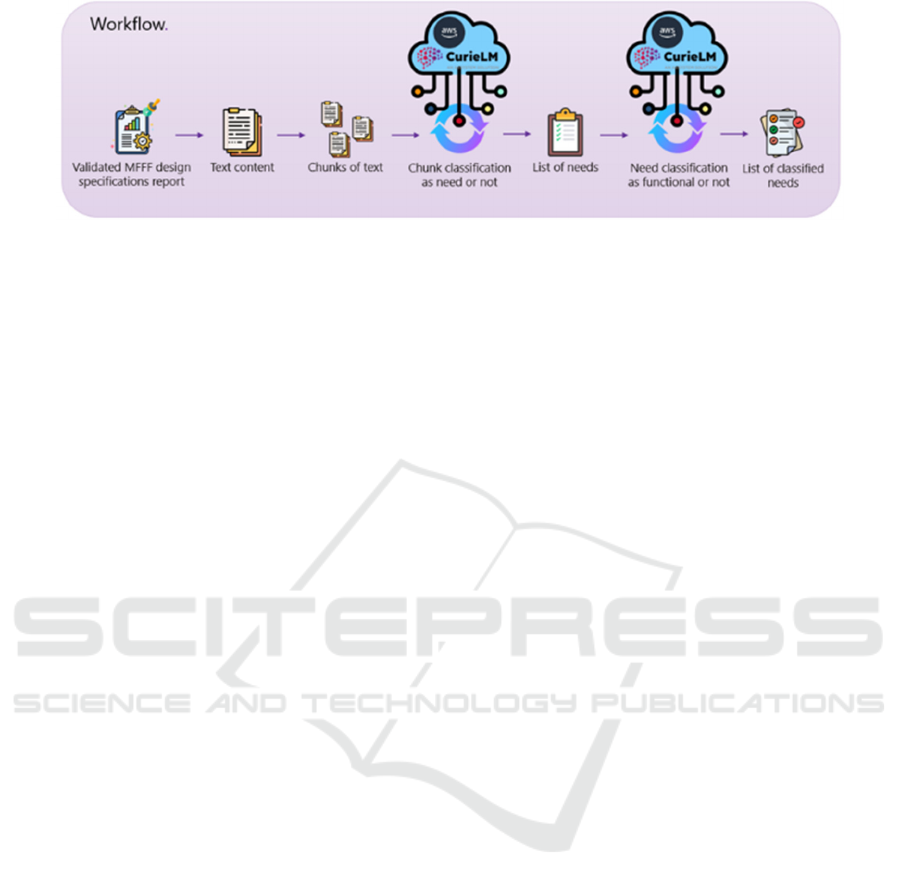

document. Figure 2 illustrates the automation process

used to produce design specifications for a MOX fuel

fabrication plant.

This step is based on the use of an artificial

intelligence model, in this case Mistral Large, to

process technical documents and generate

deliverables. In three successive activities, the system

analyzes technical data from IAEA safety standards,

MBSE-AI Integration 2025 - 2nd Workshop on Model-based System Engineering and Artificial Intelligence

398

Figure 1: Workflow to assist stakeholder and system requirement process definition.

Figure 2: Automated process for creating specification

reports for the MOX fuel fabrication plant.

writes a design report adapted to the case under study,

then consolidates all the information into a finalized

specifications report.

(1) The first is an analysis of Chapter 5 of the

IAEA safety standards (Safety of Uranium and

Plutonium Mixed Oxide Fuel Fabrication Facilities).

The CurieLM is asked to read and interpret the

technical data contained in this chapter. The result of

this first step is a design specification report for a

MOX plant.

(2) The second is the production of a design

document based on the previously created element, as

well as a technical document describing the design of

a plant of the same type.

The CurieLM is once again being asked to create

this document.

(3) The final activity is to combine the two

previous documents, merging them chapter by

chapter. Finally, the output document is a design

requirements specification.

The second sub-step uses the document

generated in the previous step to generate a list of

requirements classified as functional or non-

functional.

Figure 3 describes the automated workflow used

to extract and classify requirements from a validated

MOX Fuel Fabrication Facility (MFFF) design

specification report. This step relies on the CurieLM

artificial intelligence model to analyze the content of

the report, organize the information and produce a

ranked list of requirements.

The process begins by converting the validated

report into usable textual content. This text is then

broken down into distinct segments or “chunks” for

easier processing. From these segments, CurieLM

performs an initial classification, distinguishing

relevant portions containing needs from those that do

not. Once the needs have been identified, they are

grouped together in an initial structured list.

Transforming Systems Engineering in Nuclear Projects with Generative AI: A Path to Efficiency and Compliance

399

Figure 3: Automated workflow for extracting and classifying requirements.

In a second step, the extracted requirements are

further classified to differentiate them into two

categories: functional requirements, which define the

system's expected capabilities, and non-functional

requirements, which specify performance, safety or

reliability constraints. The result is a complete,

organized list of classified requirements, ready to be

used as the basis for subsequent design and analysis

stages.

4.1.2 Step 2: Requirements Declination

Through INCOSE Rule

We worked with the CurieLM and used Langchain

for output formatting and prompt engineering, as it

gave good reasoning performance and was able to

follow the desired output formats in previous tests on

a similar use case.

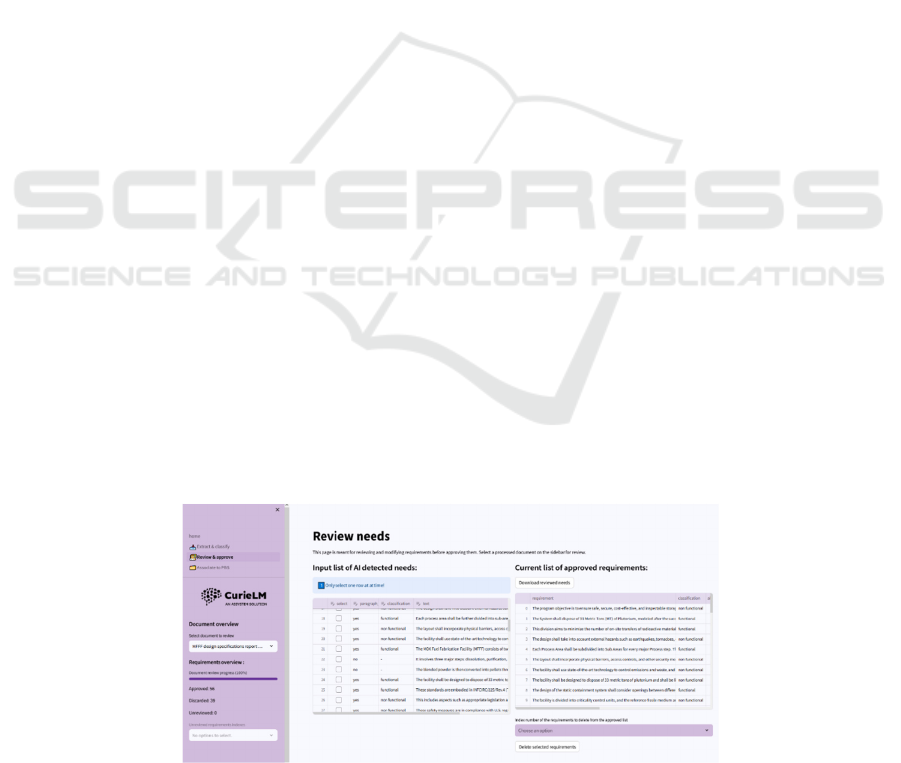

This step requires interaction with the

requirements engineer, so a dedicated interface has

been created. An overview of this interface is

provided in the Appendix.

The principle for reformulating the extracted

requirements is as follows:

Browse the file, line by line, and confirm or

deny the proposal made by the tool.

Look at the breakdown of each requirement.

Check that the requirements have been

written in accordance with INCOSE good

writing practices.

The reformulation stage is carried out using the

user interface developed as part of this project. The

requirements from the previous step are provided as

input data for this step. Two types of documents

have been integrated into the interface:

The list of requirements extracted by

CurieLM, broken down by sentence.

The list of requirements extracted by

CurieLM, broken down by paragraph.

First, the requirements engineer checks the

accuracy of the requirements. To do this, he accepts

or rejects the requirement proposal in the HMI

interface. This intermediate sub-step enables

complete verification and validation of all

stakeholder requirements extracted by the CurieLM

from the specifications. More specifically, it is

possible to:

Validate or reject the CurieLM's choice of

requirement identification.

Summarize the title of the selected

requirement.

Select editing rules to be automatically

checked by CurieLM.

Check the rules and propose a new wording

for the requirement.

Accept the CurieLM proposal or accept the

requirement with its original title.

Once the lines considered not to be requirements

have been discarded, the reformulation stage

continues, this time focusing on the quality of the

formulation of each requirement.

To carry out this step, the HMI interface

integrates INCOSE writing rules. For a selected

requirement, the user chooses the rules to be applied

and launches the verification. This verification is

performed automatically by the CurieLM. The

CurieLM indicates whether the requirement

conforms to each chosen rule and suggests a

conforming reformulation at the end of the check.

During this sub-step, it is possible to assess which

rules the CurieLM interprets correctly and which it

does not. Once the rules have been applied to the

requirement, the requirement engineer chooses

between validating the reformulation proposed by the

CurieLM or retaining the original formulation. Once

this choice has been made, the requirement is

approved and added to the final list of requirements

to be returned.

Initially, twenty INCOSE rules were

implemented to assess formulation quality. The first

requirements were checked against the twenty

CurieLM rules. However, it soon became apparent

that some rules were not correctly considered by the

CurieLM. In fact, some rules add too much

MBSE-AI Integration 2025 - 2nd Workshop on Model-based System Engineering and Artificial Intelligence

400

interpretation to the CurieLM, resulting in a

reformulation that is too far from reality that is

considered as hallucinations. For the rest of the

experiment, these rules were discarded. In

perspective, it would be interesting to prompt the

CurieLM in such a way as to limit these counter-

productive interpretations.

Here are some of the INCOSE rules that have

been removed following this phase of

experimentation:

R2: Use the active voice in the main

sentence structure of the need or

requirement statement, with the responsible

entity clearly identified as the subject of the

sentence.

R6: Use appropriate units when stating

quantities; units of measurement for all

numbers must be explicitly stated.

R10: Avoid open-ended clauses such as

“including but not limited to”, “etc” and

“and so on”.

R23: Avoid parentheses and brackets

containing subordinate text.

R24: Explicitly list sets instead of using a

group name to name the set.

R27: Avoid relying on headings to explain

or understand the requirement.

R30: Explicitly express the propositional

nature of a condition for a single action,

rather than giving lists of actions for a

specific condition.

R34: Use “each” instead of “all”, “any” or

“both” when quantifying universally.

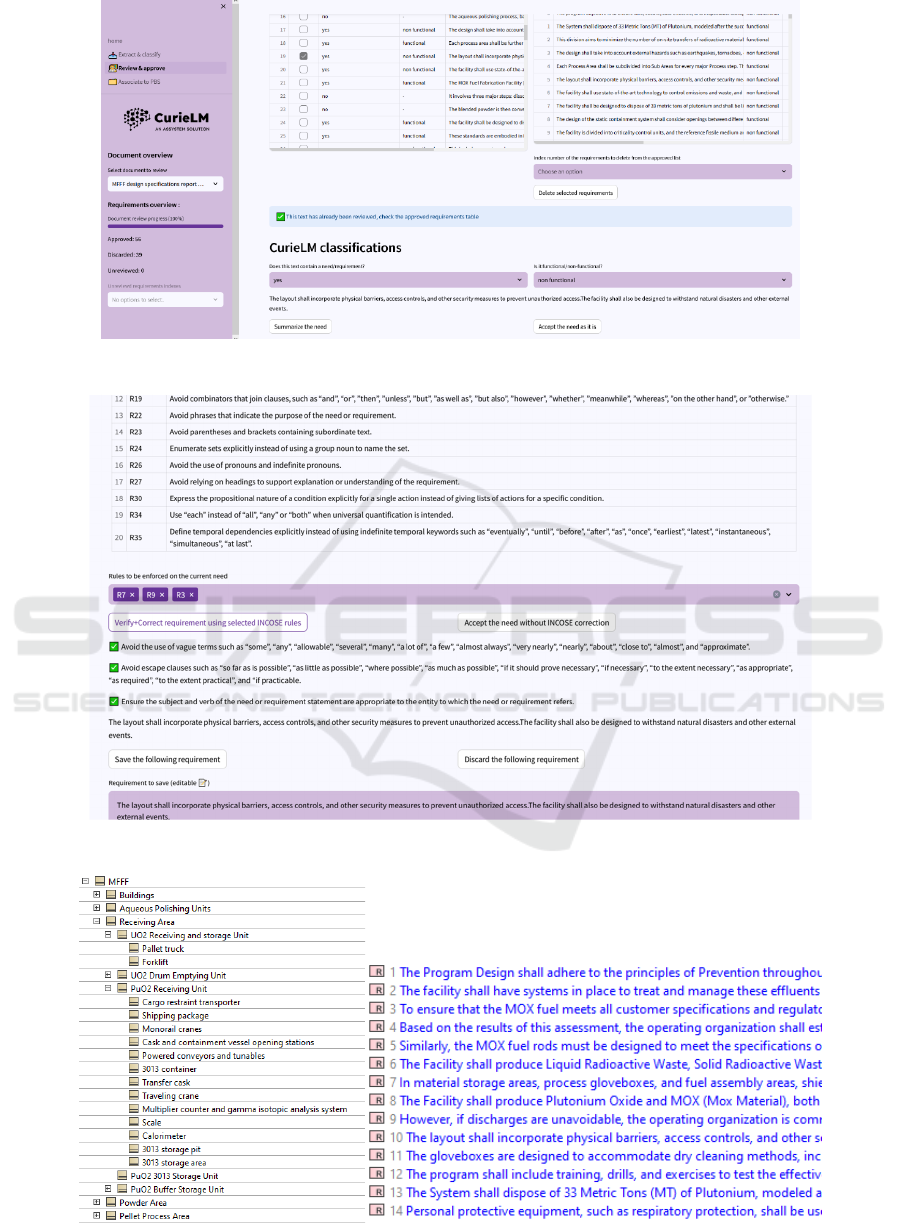

4.1.3 Step 3 & 4: SysML Modelling

Steps 3 and 4 consist in implementing the data in a

tool used in MBSE and implementing the SysML

language. They will not be detailed in the rest of this

article. Stakeholder needs have been integrated as

requirements objects and PBS elements as blocks.

This implementation can be extended to other

languages, such as that used in Capella (Roques,

2017) or other system modelling tools. An overview

of data as integrated into a modelling tool is provided

in the Appendix.

4.1.4 Step 5: Requirements Allocation to

PBS

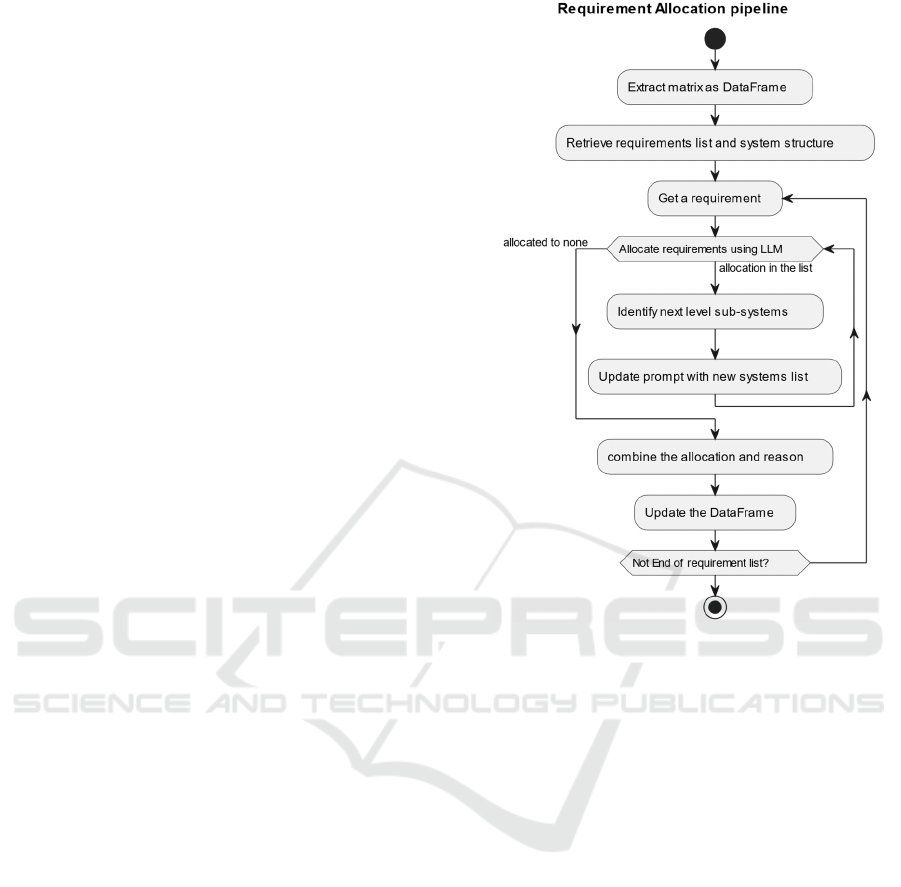

As for steps 1 and 2, we worked with the CurieLM.

One call is made per requirement and per group of

subsystems. For each group of subsystems, the

CurieLM indicates which systems are affected by the

requirement and returns an explanation.

Figure 4: Description of the action to automatically allocate

requirements to the PBS.

The tests were carried out at different

temperatures (i.e. the LLM parameter that sets the

“creativity” in the response from zero to one). Zero

temperature (almost zero in our case, since Langchain

does not allow zero temperature) seems to show

better results and more consistent responses from one

call to the next, which seems to generate more reliable

outputs that will be easier and quicker for the

requirement engineer to check before saving and

sending them to the modelling tool.

The requirements allocation is presented in matrix

form, where the requirements are the rows, and the

PBS elements are the columns. Each positive element

in the matrix indicates an allocation between the

requirement and the corresponding PBS element. The

sub-steps followed to achieve these allocations are

illustrated in Figure 4.

From the elements in the model created in the

system modeling tool, three elements are retrieved:

the list of requirements, the PBS elements and their

hierarchical structure (e.g. system X is made up of

subsystems X.1, X.2 and X.3). Then, for each

requirement, CurieLM allocates the requirement to

the corresponding level 1 PBS elements. If these

Transforming Systems Engineering in Nuclear Projects with Generative AI: A Path to Efficiency and Compliance

401

systems contain subsystems, the prompt is updated

with the list of level 2 subsystems and CurieLM

performs allocations to the second level of the PBS.

This process is repeated down to level N, the lowest

level in the PBS hierarchy. This process replicates

what a systems engineer would do on the same task,

i.e. proceed by iteration and recursion.

This step has also been integrated into the user

interface described above. It enables the requirement

engineer to select a list of requirements revised from

the previous steps and a PBS, and to launch the

allocation suggestion. He can then view the result in

the form of a matrix in which CurieLM justifies his

allocation suggestion.

When the engineer has finished reviewing CurieLM

results, he can use the export button to export a file

containing the list of allocations (in Excel format) and

inject it into the system modelling tool of his choice.

In summary, the use of an LLM was able to assist and

guide a requirements engineer through the process of

defining stakeholder requirements. Starting from

technical documentation describing a system of similar

interest and the elements to be considered as described

by a safety organization (a major stakeholder in a

nuclear facility project), he was guided through the

process to the creation of a requirements/system

allocation matrix. The results and associated gains are

presented in the following section.

5 RESULTS

5.1 Comparison Approach

A fully human and an intelligently assisted run were

performed in parallel with the development of the

CurieLM pipeline. We asked a system engineer to

take the same input data (i.e. specifications and PBS)

and replicate the steps by hand, without the help of

the assistant. The goal is to compare the results and

quantify the time savings brought by AI. The exercise

given to the system engineer consists of the following

steps:

Step 1 - Manual Requirements Extraction: During

this initial phase, a 16-page document detailing the

MOX Fuel Fabrication Facility Design Specification

Report was provided for manual analysis. The task

consisted of a thorough review of the document to

identify and extract all discernible requirements. The

extracted requirements were then classified according

to their functional or non-functional nature. All

duplicate requirements were identified and eliminated

from the extracted requirements set.

Step 2 - Requirements Rewriting The second

phase focused on rewriting the extracted

requirements (excluding identified duplicates) to

ensure adherence to the pre-selected INCOSE

guidelines. These guidelines include a comprehensive

set of rules designed to improve clarity, conciseness,

completeness, and accurate quantification of the

requirements. The rewritten requirements were then

classified as either fully compliant with the selected

INCOSE rules or considered to be already well-

written in their original form.

The selected INCOSE rules were as follows:

R1: Use the definite article "the" instead of the

indefinite article "a".

R7: Avoid using vague terms such as "some",

"all", "allowable", "several", "many", "some",

"almost always", "very near", "nearly", "about",

"close to", "almost", and "approximate".

R9: Avoid escape clauses such as "as far as

possible", "as little as possible", "if possible", "if

necessary", "to the extent necessary", "as

appropriate", "as required", "as far as possible",

and "if possible".

R12: Use a separate clause for each condition or

qualification.

R26: Avoid using double-meaning pronouns and

verbs: Avoid using indefinite pronouns and

pronouns.

R37: Explicitly define temporal dependencies:

Explicitly define temporal dependencies instead

of using temporal keywords such as "eventually",

"until", "before", "after", "as", "once", "at the

earliest", "at the latest", "instantaneous",

"simultaneous", "finally".

Step 3,4 and 5 - Allocation of requirements in a

modeling tool: the rewritten requirements were then

loaded into the modeling tool. Each individual

requirement was assigned to the most relevant

elements of the PBS in the tool interface.

5.2 Operation Duration

This step showed a significant reduction in the time

required, from 8.5 hours to 1 hour. Then, the extracted

requirements were declined according to the INCOSE

(International Council of Systems Engineering) rules,

reducing the processing time from 16 hours to 2 hours

thanks to automation. The requirements were then

modeled in an engineering platform, integrating the

identified needs and the declined requirements with a

significant time saving. The allocation of requirements

to the Product Breakdown Structure (PBS) was also

optimized, a time saving from 7.5 hours to 2.5 hours.

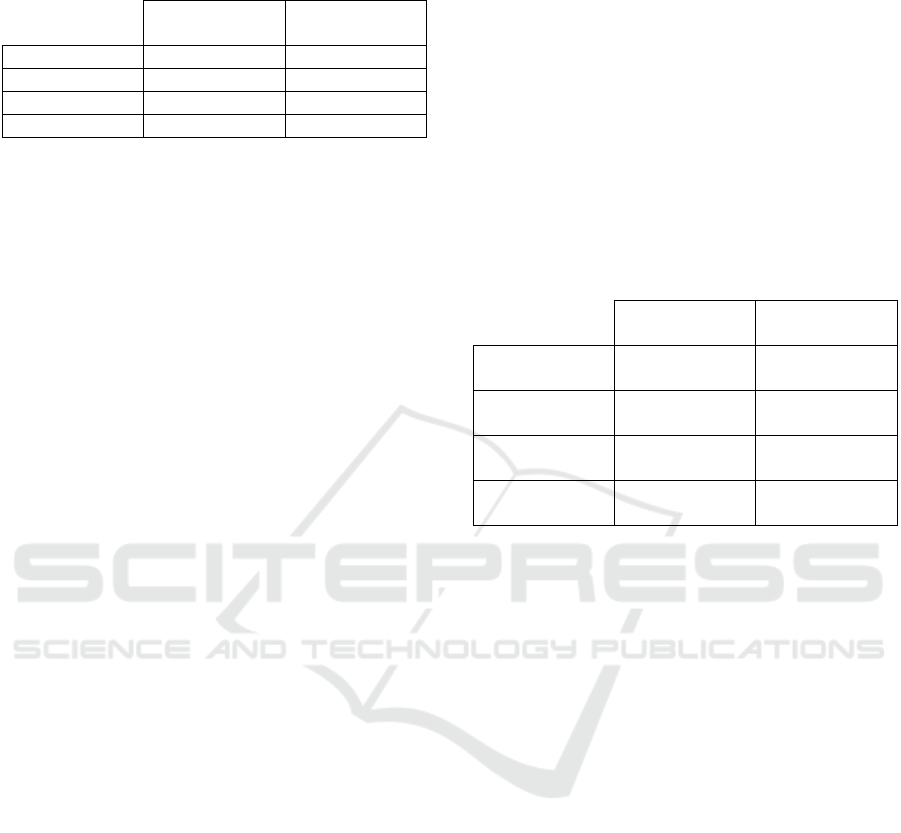

These results are summarized in Table 1.

MBSE-AI Integration 2025 - 2nd Workshop on Model-based System Engineering and Artificial Intelligence

402

Table 1: Duration comparison between manual and

intelligent assisted operation.

Conventional CurieLM

Assisted

Step 1 8,5 h 1 h

Step 2 16 h 2 h

Step 3-4-5 7,5 h 2,5 h

Total 31,5 h 5,5 h

5.3 Quality

The extraction file obtained with the extraction tool

gives us 159 identified requirements. Most of the

major requirements of the specifications were

identified by it. After analysis and verification, it

appears that the number of requirements is lower

(around 73). This is potentially due to the way the

specifications were broken down by the tool to extract

the requirements. Some of the requirements selected

by the tool are indeed too vague or imprecise, so it is

wise to remove them from the list.

For example, here is an extracted requirement that

should have been removed from the final list: "223 -

The program must also include provisions for record

keeping and reporting to support continuous

improvement". The program is too vague here, it lacks

a context that the specifications do not provide a

priori. In addition, the relevant provisions are not

explained, which does not allow us to understand how

this requirement must be tested and verified.

Another requirement that was confirmed after

analysis was "103 - The MFFF shall use proven

European technology and shall be adapted to comply

with U.S. requirements". This is still a very high level

requirement, but it is consistent with most good

drafting practices and is not easy to control and

manage.

Unlike automated extraction, extraction with

CurieLM gives much less output requirements. The

splitting at the time of extraction was apparently not

the same as for the extraction tool, hence a list of

requirements different from the first list provided.

The identified requirements often have longer

titles, with several sentences and even several topics.

This last point makes the understanding of the

requirement more difficult. For example: "For cases

where misidentification of containers could pose a

hazard, provisions for easy identification of the content

shall be used, such as unique colors, shapes, and

valves. Additionally, technical provisions for

inspection and maintenance of containers classified as

items important to safety shall be available. The MFFF

shall receive PuO2 from the Pit Disposition and

Conversion Facility (PDCF) in containers that meet

DOE standards. The PuO2 shall meet specification

requirements of DCS and shall be shipped by methods

that ensure the security of the material, under DOE

authority until inside the MFFF secured area. Both the

PDCF and the MFFF shall provide for sufficient

storage of PuO2 to ensure a continuous flow to the

MFFF to satisfy the demand curve for the material.".

This requirement is abstracted from CurieLM, but it

contains different topics and too much information to

be considered a single requirement.

Metrics for the comparison are synthetized in the

Table 2.

Table 2: Comparison between automated operation and

CurieLM assisted extraction results.

Conventional

CurieLM

Assisted

Extracted

requirements

159 94

Approved

requirements

73 56

Reworked

Requirements

31 26

Discarded

Requirements

86 38

5.4 Results Discussions

Time saving is the element that stands out the most

from the comparison between the two approaches (i.e.

engineer with or without CurieLM). When carried out,

activities with CurieLM make it possible to carry out

the same volume of work as that of the systems

engineer in 2 or 3 times less time. Nevertheless, the

work of the systems engineer remains very efficient,

particularly in terms of decision-making and

arbitration on the identification, allocation, or even

formulation of needs. This efficiency is obviously

closely related to the experience and expertise of the

engineer. On the other hand, the precision and quality

of the AI results are generally lower than those of the

engineer. The automatic work of the AI is not linear

and homogeneous, some tasks were more relevant to

be carried out with the CurieLM while other tasks

brought nothing (even from the point of view of time

saving because the engineer had to rework the results

of the LLM in all cases).

The first observation is that it is necessary to find

a fair collaboration between the engineer and the AI

to save time in this type of task without losing quality.

The use of CurieLM allows engineers to save

considerable time in the early design phases. In this

context, the organization is often not yet fixed, and

the multiplicity of roles and responsibilities can

Transforming Systems Engineering in Nuclear Projects with Generative AI: A Path to Efficiency and Compliance

403

accumulate. Having a tool that reduces the time

required to structure these roles, such as the

construction of a technical specification, a PBS or

verification activities.

The systems engineer provides results that are

applicable to any project. Conversely, even if the AI

results are consistent, they must necessarily be

verified, or even reworked, to be usable in a project.

The activity of the systems engineer therefore

remains essential and his volume of activity must not

be reduced compared to the LLM. These activities

must include considering and collaborating with the

LLM in the role of systems engineer.

6 PERSPECTIVES AND

CONCLUSIONS

The first perspective concerns the improvement of

workflows assisted by artificial intelligence, in order to

achieve more precise and efficient extraction and

classification of requirements. To achieve this, it will

be necessary to develop new algorithms and integrate

advanced machine learning techniques. In addition, the

development of the user interface intended for

engineering teams will play a key role. By integrating

their feedback, the tool will be able to gradually evolve

to adapt to the concrete needs of users. This approach

will promote smooth adoption and optimized daily use.

The expansion of the automation workflow to

other system engineering themes identified in the

project represents an area of development. This will

make it possible to integrate other key activities such

as the automatic generation of architectures, the

analysis of interfaces or the allocation of

requirements to the subsystems concerned. By

systematizing these approaches, the different stages

of the project life cycle can be optimized.

The integration of text-model systems for SysML

generation in the nuclear domain offers significant

improvement prospects in terms of efficiency,

accuracy and traceability of the system design

process. Although significant progress has been

made, challenges remain, particularly regarding the

ambiguity of natural language, the complexity of

system management and the integration of nuclear

domain-specific knowledge.

REFERENCES

Ahmad, K., Abdelrazek, M., Arora, C., Bano, M., &

Grundy, J. (2022). Requirements Engineering for

Artificial Intelligence Systems: A Systematic Mapping

Study. http://arxiv.org/abs/2212.10693

Akundi, A., Ontiveros, J., & Luna, S. (2024). Text-to-

Model Transformation: Natural Language-Based

Model Generation Framework. Systems, 12(9), 369.

https://doi.org/10.3390/systems12090369

Alaoui, M. El, Chapurlat, V., Rabah, S., Richet, V., &

Plana, R. (2023). An approach for ontology-based

research and recommendation on systems engineering

projects. Procedia Computer Science, 225, 1350–1359.

https://doi.org/10.1016/j.procs.2023.10.123

Ben Nasr, S. (2016). Mining and Modeling Variability from

Natural Language Documents: Two Case Studies.

https://inria.hal.science/tel-01388392v1

Bouhoun, Z., Allali, A., Cocci, R., Assaad, M. A., Plancon,

A., Godest, F., Kondratenko, K., Rodriguez, J., Vitillo,

F., Malhomme, O., Bechet, L. B., & Plana, R. (2024).

CurieLM: Enhancing Large Language Models for

Nuclear Domain Applications. EPJ Web of

Conferences, 302, 17006. https://doi.org/10.1051/

epjconf/202430217006

Chami, M., Zoghbi, C., & Bruel, J.-M. (2019). A First Step

towards AI for MBSE: Generating a Part of SysML

Models from Text Using AI (pp. 123–136).

Chapurlat, V. (2013). UPSL-SE: A model verification

framework for Systems Engineering. Computers in

Industry, 64(5), 581–597. https://doi.org/10.

1016/j.compind.2013.03.002

Cocci, R., Huang, S., Lesigne, Q., Suchet, P., Montagne, L.,

Roumili, E., Ali, A., Assaad, M. A., Vitillo, F.,

Benmiloud-Bechet, L., & Plana, R. (2024).

Requirements Management Analytics Enabled by Model

Based System Engineering and Artificial Intelligence for

Decommissioning and Dismantling Projects.

DCS. (2006). License Application Package Overview

MOX Fuel Fabrication Facility.

INTERNATIONAL ATOMIC ENERGY AGENCY.

(2003). Status and Advances in MOX Fuel Technology,

Technical Reports Series No. 415 (Issue 415). IAEA.

https://www.iaea.org/publications/6562/status-and-

advances-in-mox-fuel-technology

INTERNATIONAL ATOMIC ENERGY AGENCY.

(2023a). Safety of Uranium and Plutonium Mixed

Oxide Fuel Fabrication Facilities, IAEA Safety

Standards Series No. SSG-7 (Rev. 1) (Issue SSG-7

(Rev. 1)). IAEA. https://www.iaea.org/publications/

15079/safety-of-uranium-and-plutonium-mixed-oxide-

fuel-fabrication-facilities

INTERNATIONAL ATOMIC ENERGY AGENCY.

(2023b). Safety of Uranium Fuel Fabrication Facilities,

IAEA Safety Standards Series No. SSG-6 (Rev. 1)

(Issue SSG-6 (Rev. 1)). IAEA. https://www.

iaea.org/publications/15078/safety-of-uranium-fuel-

fabrication-facilities

ISO, & IEC. (2023a). ISO/IEC/IEEE ISO/IEC/IEEE

15288:2023 Systems and software engineering —

Software life cycle processes. International

Organization for Standardization, 1.

ISO, & IEC. (2023b). ISO/IEC/IEEE ISO/IEC/IEEE

24641:2023 Systems and software engineering —

MBSE-AI Integration 2025 - 2nd Workshop on Model-based System Engineering and Artificial Intelligence

404

Methods and tools for model-based systems and

software engineering. International Organization for

Standardization, 1.

Johnson, J. V, & Brabazon, E. J. (1993). Design of the Mox

Fuel Fabrication Facility.

Luttmer, J., Prihodko, V., Ehring, D., & Nagarajah, A.

(2023). Requirements extraction from engineering

standards - systematic evaluation of extraction

techniques. Procedia CIRP, 119, 794–799.

https://doi.org/10.1016/j.procir.2023.03.125

McDermott, T., DeLaurentis, D., Beling, P., Blackburn, M.,

& Bone, M. (2020). AI4SE and SE4AI: A Research

Roadmap. INSIGHT, 23(1), 8–14.

https://doi.org/10.1002/inst.12278

Mengist, A., Buffoni, L., & Pop, A. (2021). An integrated

framework for traceability and impact analysis in

requirements verification of cyber–physical systems.

Electronics (Switzerland), 10(8). https://doi.org/10.

3390/electronics10080983

Nastov, B., Chapurlat, V., Dony, C., & Pfister, F. (2015). A

verification approach from MDE applied to model based

systems engineering: XeFFBD dynamic semantics.

Complex Systems Design and Management -

Proceedings of the 5th International Conference on

Complex Systems Design and Management, CSD and M

2014. https://doi.org/10.1007/978-3-319-11617-4_16

Necula, S. C., Dumitriu, F., & Greavu-Șerban, V. (2024). A

Systematic Literature Review on Using Natural

Language Processing in Software Requirements

Engineering. In Electronics (Switzerland) (Vol. 13,

Issue 11). Multidisciplinary Digital Publishing Institute

(MDPI). https://doi.org/10.3390/electronics13112055

OMG. (2006). OMG SysML Specification. OMG Systems

Modeling Language.

Patel, A., Maheshwaran, Y., & Santhya, P. (2024). Easing

Adoption of Model Based System Engineering With

Application of Generative AI. 2024 IEEE Space,

Aerospace and Defence Conference (SPACE), 871–

874. https://doi.org/10.1109/SPACE63117.2024.

10667868

Petnga, L. (2019). Graph‐based Assessment and Analysis

of System Architecture Models. INCOSE International

Symposium, 29(1). https://doi.org/10.1002/j.2334-

5837.2019.00644.x

Plehn, C. (2018). A method for analyzing the impact of

changes and their propagation in manufacturing

systems (Vol. 333). Herbert Utz Verlag.

Roques, P. (2017). Systems Architecture Modeling with the

Arcadia Method: A Practical Guide to Capella. In

Systems Architecture Modeling with the Arcadia

Method: A Practical Guide to Capella.

https://doi.org/10.1016/C2016-0-00854-9

van Remmen, J. S., Horber, D., Lungu, A., Chang, F., van

Putten, S., Goetz, S., & Wartzack, S. (2023). Natural

language processing in requirements engineering and

its challenges for requirements modelling in the

engineering design domain. Proceedings of the Design

Society, 3, 2765–2774. https://doi.org/10.1017/pds.

2023.277

Weston, N., Chitchyan, R., & Rashid, A. (2009). A

framework for constructing semantically composable

feature models from natural language requirements.

Proceedings of the 13th International Software Product

Line Conference.

Winkler, J., & Vogelsang, A. (2017). Automatic

classification of requirements based on convolutional

neural networks. Proceedings - 2016 IEEE 24th

International Requirements Engineering Conference

Workshops, REW 2016. https://doi.org/10.

1109/REW.2016.16

Zhang, J., & Yang, S. (2024). Recommendations for the

Model-Based Systems Engineering Modeling Process

Based on the SysML Model and Domain Knowledge.

Applied Sciences (Switzerland), 14(10).

https://doi.org/10.3390/app14104010

Zhao, L., Alhoshan, W., Ferrari, A., & Letsholo, K. J.

(2022). Classification of Natural Language Processing

Techniques for Requirements Engineering.

http://arxiv.org/abs/2204.04282

.

APPENDIX

Figure 5: View of the requirements approval page.

Transforming Systems Engineering in Nuclear Projects with Generative AI: A Path to Efficiency and Compliance

405

Figure 6: Classification and summary view.

Figure 7: INCOSE Auto Check View.

Figure 8: PBS and Requirements modelled in a system modelling tool.

MBSE-AI Integration 2025 - 2nd Workshop on Model-based System Engineering and Artificial Intelligence

406