Iterative Diagnosis-Driven Augmented Generation (IDDAG) for

Programmatic 3D CAD

Thomas Paviot

1

a

, Virginie Fortineau

1 b

and Samir Lamouri

2,3 c

1

meeDIA, 15 rue Glais Bizoin, 35000 Rennes, France

2

Arts & M´etiers, 151 bd de l’Hˆopital, 75013 Paris, France

3

LAMIH CNRS, Universit´e Polytechnique Hauts-de-France, Campus Mont Houy, 59313 Valenciennes Cedex 9, France

Keywords:

CAD, 3D, LLM, Context Augmentation, BRep.

Abstract:

This paper presents a novel approach for automated generation of 3D CAD models using Large Language

Models (LLMs) within Model-Based Systems Engineering workflows. We introduce Iterative Diagnosis-

Driven Augmented Generation (IDDAG), a methodology combining programmatic geometry creation with

systematic diagnostic feedback. The approach leverages a dedicated API for exact Boundary Representation

(B-Rep) geometry generation, augmented by a closed-loop architecture that provides iterative refinement based

on syntactic, runtime, and geometric analysis. Unlike existing methods requiring extensive training datasets

or producing approximate geometries, our solution generates t opologically valid, parameterized models while

maintaining traceability to engineering requirements. Results demonstrate progressive geometric refinement

across iterations, with the diagnostic feedback mechanism effectively identifying and correcting topological

inconsistencies.

1 INTRODUCTION

In the context of Indu stry 4.0’s digitalization of in-

dustrial value chains, the integration between Model-

Based System Engineering (MBSE) a nd Computer-

Aided De sig n (CAD) becomes essential to facilitate

the digitization of physical product development pro-

cesses (Meussen, 2021).

3D CAD mode ls are particularly critical as they

represent the exact geometric definition that will be

used throughout the product lifecycle, at each stage

of the digital c hain (visualization, simula tion, au to-

mated manufacturing, etc.). Integrating 3D rep resen-

tation w ithin an MBSE approach ther e fore imposes

stringent requirements: models must comply with

structural and semantic consistency constraints with

other system views (functio nal, logical, physical ar-

chitectures); their c onstruction must follow a tr ace-

able process, where each design choice can be jus-

tified against initial req uirements; their maintenance

over tim e requires precise and unambiguous parame-

terization enabling adaptation to evolving needs. Cre-

a

https://orcid.org/0000-0002-3380-8845

b

https://orcid.org/0000-0001-7043-4849

c

https://orcid.org/0000-0003-3868-9280

ating these 3D models requ ires significant technical

expertise, substantial tim e investment, and the use of

complex professional CAD software - making these

costly processes.

Concurrently, the development of Large Language

Models (LLMs) reveals rema rkable opp ortunities in

the Industry 4.0 domain (Bourdin et al., 2024).

This paper thu s aims to address two research ques-

tions: is it possible, using LLMs, to automa te all or

part of the process of creating 3 D models from a set of

requirements? If so, how can w e ensure the explain-

ability of the provided solution to enable validation of

choices and theref ore design traceability? Industrial

3D CAD processes utilize Boundary Representation

(B-Rep), as it offers mathematically exact geometry

representation. While recent AI advances have en-

abled notable progress in p rocessing appro ximate ge-

ometries (particularly through meshes) with applica-

tions in entertainment, visualization, and 3D printing,

research concern ing exact representation remains less

numerous and advanced.

As a consequence, the paper is structured as fol-

lows: Section 2 presents the state of the art regarding

LLM utilization for B-Rep generation and its current

limitations. Section 3 introduces our two scientific

contributions: a programmatic metho dology coupled

474

Paviot, T., Fortineau, V. and Lamouri, S.

Iterative Diagnosis-Driven Augmented Generation (IDDAG) for Programmatic 3D CAD.

DOI: 10.5220/0013443500003896

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 13th International Conference on Model-Based Software and Systems Engineering (MODELSWARD 2025), pages 474-480

ISBN: 978-989-758-729-0; ISSN: 2184-4348

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

with an iterative context enrichment mechanism f or

solution quality improvement. Section 4 details the

experimental validation protocol and results. Fina lly,

Section 5 discusses the contributions relative to ex-

isting approaches and identifies future research direc-

tions.

2 RELATED WORK

2.1 B-Rep Model

The BRep model describes the mathematically exact

geometry of a component through non-volumetric e l-

ements that com pose its surface. These elements c on-

sist of faces, edges, and vertices arranged in an adja-

cency graph. A face corresponds to a surface patch, an

edge to an intersection curve segment between at least

two surfaces, and a vertex to an intersection point be-

tween two distinct curves (Mor tenson, 1997).

2.2 Large Language Models

A Large Language Model (LLM) is an artificial in-

telligence system based on a transformer architecture,

trained on massive volumes of textual data (ranging

from hundreds of billions to several trillion tokens)

for self-supervised learn ing purposes. The se models

are cap able of Natural Language Processing (NLP)

and can perform various complex linguistic and cog -

nitive tasks suc h as translation, reasoning, program-

ming, and pr oblem-solving, either in few-shot mode

(with few examples) or zero-sh ot mode (without ex-

amples). Their lea rning capacity e merges from at-

tention mechanisms allowing them to capture long-

term dep e ndencies in textual seq uences and acquire

sophisticated contextual representatio ns of language

(Naveed et al., 2024).

Regarding coding tasks, (Liang et al., 2024) re-

veal that LLMs demonstrate their greatest efficiency

when tasks are structured with clear context, for ex-

ample targeted mo difications of existing code, data

visualization tasks, o r documented API implementa-

tion. Efficiency is maximized when source code is

available as context, objectives are well- defined, and

the user possesses sufficient technical expertise to for-

mulate precise queries.

2.3 LLMs for B-Rep Geometry

Generation

In the field of automatic BRep geometry generation,

scientific literatu re works can be classified in to two

categories: a) those that directly produce BRep g e-

ometry; b) tho se that produce an intermediate artifact

that drives geometry creation.

B-Rep Geometry Generation. This approach is

chosen, fo r example, by ( Xu et al., 2024) (Zhang

et al., 2023) (Zhang et al., 2024). The algorithm gen-

erates a graph representing BRep topology and ge-

ometry. These approac hes use neural networks, but

not directly LLMs. A preliminary learning phase is

necessary, involving datasets of several hundred or

thousand examples. Then validation tests are per-

formed on data not included in the initial dataset.

These works face issues of precision , explainability,

and lack of formal guarantees on the production of

topologically valid CAD models (risks of generat-

ing non-manifold geometries, or surfaces with self-

intersections).

Indirect Generation. (Wu et al. , 202 3) introduce

CAD-MLLM, a system using multimodal LLMs

(text, image) to gen erate CAD models from various

inputs (text, ima ges, point clouds). In this case, ge-

ometry is not directly generated by the LLM: the out-

put is a geometry description in the form of a ”com-

mand sequence,” which drives geometry construction

(a method th a t falls within the framework of Para-

metric Macro Approaches introduced by (Mun et al.,

2003)). Each sequence element is identified by a

mnemonic associated with a token in the fine-tuning

phase of the chosen LLM. According to the authors,

CAD-MLLM presents the following limitations: the

description in the form of basic op eration sequences

uses an ad hoc model composed of a small number of

operations in linear form. It is work centere d on exact

geometry reconstruction, but not generation from re-

quirements. (Yuan et al., 2024) Zhang et al. propose a

very similar approach and report the same limitations.

2.4 Open Issues

We identify three significant barriers in the presented

works:

• all works rely on a learning phase based on a large

dataset, which is a costly operation,

• produced geometries are limited to simple cases,

• it is not p ossible to guarantee the topological va-

lidity of generated shapes.

Finally, we note that in these works, geometry is never

related to the notions of function or requirement so

important in MBSE. In the remainder of this paper,

we propose a method to address the preceding barri-

ers.

Iterative Diagnosis-Driven Augmented Generation (IDDAG) for Programmatic 3D CAD

475

3 PROGRAMMATIC APPROACH

FOR BRep GENERATION

We therefore orient our work toward an approach that:

• ge nerates para meterized geometry programmati-

cally (see section 3.1), enabling for instance the

creation of component catalo gs with complex ge-

ometries, or inclusion in simulation optimization

loops (e.g., FEM),

• ge nerates exact, topologically consistent geome-

try,

• does not requir e LLM fine-tuning or learning, nor

datasets. We prefer context augmentation .

3.1 Programmatic Approach

Principle. Following from the previous section, we

propose a path that falls within the ”in direct gen-

eration” category of geometry, different fr om those

proposed in section 2: a ”progr ammatic” approach.

Rather than asking th e LLM to generate a command

sequence in an ad hoc model, we propose asking it to

generate a computer program to which form creation

is delegated. Two approaches can be con sidered:

• de sign a Domain Specific Language for 3D form

programming;

• use a common programming languag e

(JavaScrip t, Java, C, etc.) and a domain-specific

3D development library.

The design and implementation of a DSL present

two challenges: with its specific grammar, it re-

quires L LM fine-tuning, and thus the creation of a

sufficiently large dataset to ensure pro per learning.

Additionally, a com piler or interpreter fo r this DSL

must be developed. To overcome these difficu lties,

we choose the Python programming language in this

work.

Example and Limitations. To illustrate this ap-

proach , here is a basic ChatGPT prompt to generate

a 3D nut using Python and the free and open-source

3D CAD library pythonocc (Paviot, 2022) :

Write a python script, based on the pythonocc

library, to generate the parameterized 3D

geometry of a standard H-M10 nut.

The generated program is included in Appendix 1.

We observe that:

• the program is difficult for humans to read, except

for library specialists;

• the program, when executed, generates an error:

the BRepBuilderAPI MakePrism class does not

exist in the library, it is an LLM hallucination.

This pro grammatic approach shows its limitations

on a simple example: ChatGPT has only limited

knowledge of the utilized library and proposes a non-

existent class.

Dedicated API. To gain explainability, we seek to

obtain a m ore concise and clearer program. We pro-

pose relying on a dedicated API based on:

• a taxo nomy of elementary operations for creation,

transformation, and measurement of basic shapes

• a naming convention fo r classes and functions

methods tha t is closest to natural language. This

proxim ity to natural language improves program

readability for hum ans;

Furthermore, we propose passing textual API doc-

umentation to the LLM. This co ntextual elemen t

should enable the LLM to generate a progra m con-

forming to the provided specification, addressing the

problem raised in the previous section. The documen-

tation must be concise, to limit prompt le ngth, and

exhaustive to cove r all proposed functionalities.

3.2 Context, Metadata, Requirements,

and Knowledge

Context The structure of the prom pt passed to the

LLM is therefore:

<instructions>[...]</instructions>

<api_documentation>[...]</api_documentation>

For example:

<instructions>

Generate a Python script to create the 3D

geometry of an H-M10 nut, using the library

whose documentation is given below

</instructions>

<api_documentation>

3D Modeling Library

=================

This API allows easy creation and manipulation

of 3D geometric objects.

[...]

</api_documentation>

Requirements and Knowledge. Requirements are

part of the prompt passed to the LLM, enclosed in

<requirements></requirements>

tags. Specifica-

tions are of three types:

• functional requ irements (maximu m dimensions,

maximum mass)

MBSE-AI Integration 2025 - 2nd Workshop on Model-based System Engineering and Artificial Intelligence

476

• technical requir e ments (technology used, mater i-

als, etc.)

• various a dditional requirements (expected level of

detail, aesthetics, etc.)

Requirements are passed as text, which can rep-

resent structured (JSON, XML), semi-structured, or

unstructured information (natu ral language) depend-

ing on the context. Similarly, domain-specific knowl-

edge is passed between

<knowledge></knowledge>

tags. For example, this could be an excerpt from the

standard specifying H-M1 0 nut dimensions. Thus, the

final structure of the prompt passed to the LLM looks

like (replace the

#component

token with any compo-

nent name, for example

H-M10 nut

):

<instructions>

Write a Python program to generate

the parameterized 3D geometry of a #component:

- using the API whose documentation is given

below

- using #component metadata

- using the given knowledge elements

- respecting all listed requirements

</instructions>

<metadata>[...]</metadata>

<api_documentation>[...]</api_documentation>

<knowledge>[...]</knowledge>

<requirements>[...]</requirements>

The Python program generated this way offers better

human readability and creates th e following graphical

3D geometry (see 1):

Figure 1: Fixed 3D nut generation.

4 DIAGNOSIS-DRIVEN

AUGMENTED GENERATION

Despite the precautions taken previously (dedicate d

API, concise docume ntation in context), output qual-

ity cannot be guaranteed: the generated program may

still present syntactic errors, the geometry creatio n

may prove mathematically un feasible, or the geom-

etry may be topologically incorrect. To ad dress these

deficiencies and enhance reliability, we pro pose aug-

menting the LLM with reflective capabilities by pro-

viding a set of information constructed a posteriori,

based on the LLM output. This involves e nriching the

LLM prompt context with a diagnostic r eport com-

prising information on:

• syntactic compliance of the generated progr a m,

utilizing static code analysis tools

• program execution success a nd geometry cre-

ation, derived fr om Python console output

• analysis of the produce d geometry (topological

coherence, inertial elements, bounding volume,

etc.), performed by a dedicated software compo-

nent

The generated diagnosis thus comprises th ree dis-

tinct sectio ns:

<diagnosis>

<static_analysis>[...]</static_analysis>

<runtime_analysis>[...]</runtime_analysis>

<geometric_analysis>[...]</geometric_analysis>

</diagnosis>

Once th is diagnostic report is generated, it is

added to the context and returned to th e LLM for po-

tential modification requests. This process iterates un-

til a satisfactory response is obtained, with the user

determining whether to initiate a new generation cy-

cle. Thus, during successive iterations, the prompt

passed to the LLM the second time (after the first it-

eration) follows this schematic XML model:

<input>

<instructions>[...]</instructions>

<metadata>[...]</metadata>

<api_documentation>[...]</api_documentation>

<knowledge>[...]</knowledge>

<requirements>[...]</requirements>

</input>

<output>[... first LLM response ...]</output>

<diagnosis>

<static_analysis>[...]</static_analysis>

<runtime_analysis>[...]</runtime_analysis>

<geometric_analysis>[...]</geometric_analysis>

</diagnosis>

<input>

<instructions>Given the diagnostic report,

update the 3D generation code.

</instructions>

</input>

After the second iteration, the following is added

to the previous prompt:

<output>[... second LLM response ...]</output>

<diagnosis>

<static_analysis>[...]</static_analysis>

<runtime_analysis>[...]</runtime_analysis>

<geometric_analysis>[...]</geometric_analysis>

</diagnosis>

<input>

<instructions>Given the second diagnostic

report, update the 3D generation code.

</instructions>

</input>

Iterative Diagnosis-Driven Augmented Generation (IDDAG) for Programmatic 3D CAD

477

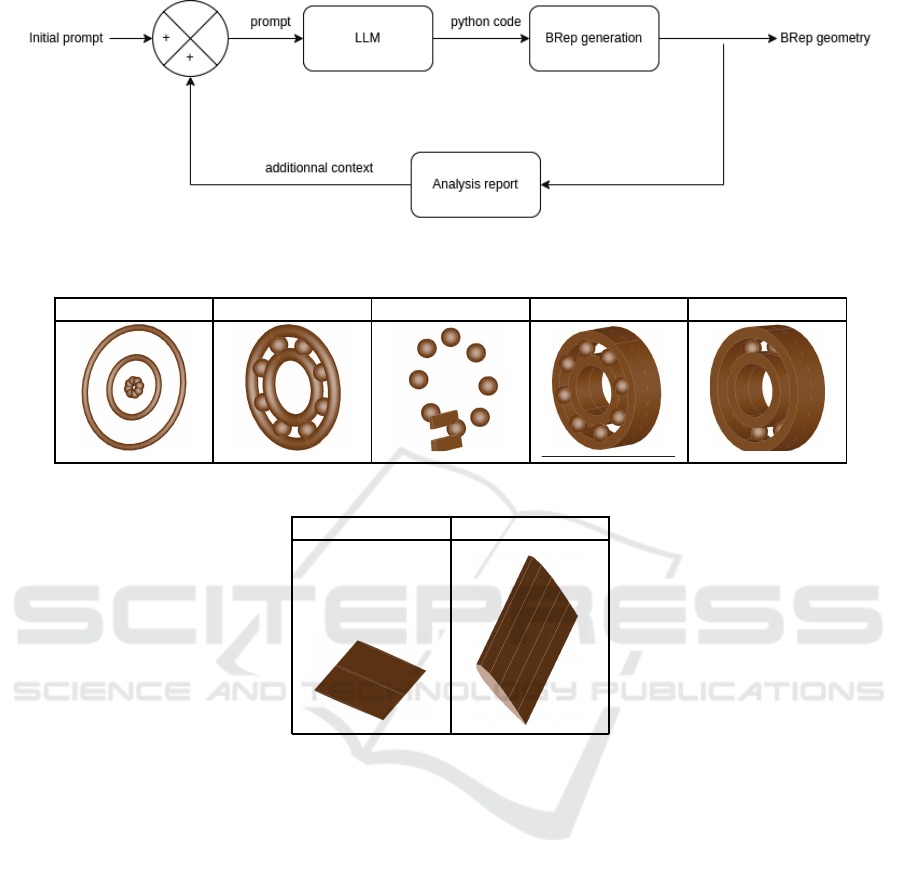

and so forth. This workflow process can be il-

lustrated by the synoptic diagram in Figure 2, which

adopts closed-loop control system semantics.

5 EXPERIMENTS

The experimen ta l validation was c onducted using

Python 3.10 and the latest pythonocc version. The

Large Language Model used was Claude Haiku, se-

lected fo r its balance of performance and response

speed. Two distinct test cases were implemented to

evaluate the IDDAG methodology: a standardized

mechanical component (ball bearing) and an aerody-

namic surface (airplane wing). For each experiment,

we analyze the geometric evolution across successive

iterations and examine convergence characteristics.

Ball Bearing. The first experim e nt focused on gen-

erating a 6203-series radial ball bearing , chosen for

its well- defined geometric constraints and standard-

ized dimensions. This is the only requirement.

Tab le 1 illustrates the geometric evolution across

five iterations. Initial generation (n=1) pr oduced a

simplified cylindrical representation lacking internal

components. Subsequent iterations progressively re-

fined the model: n=2: Addition o f basic rolling el-

ement placeholders, n=3: Implementatio n of correct

race profiles, n=4: Refinement of ball ge ometry and

spacing n=5: Final optimization of contact surfaces

and clearances.

The diagnostic fe edback loop identified and cor-

rected multiple issues, including topological inconsis-

tencies in race-to-ball interfaces (n=2→n=3) and ge-

ometric valid ity constraints for rolling element distri-

bution (n=3→n=4). 1

Airplane Wing. The second experiment involved

generating an aircraft win g section using the NACA

0012 airfoil profile, chosen for its well-documented

geometry and extensive validation data. The sp ec-

ification included a 1000m m span, 200mm chor d

length, and pr ecise adherence to the NACA 0012 co-

ordinate system. The evolution shown in Table 2

demonstra te s sign ificant challen ges in initial geom-

etry creation: n=1: Failed mathema tica l generation

of intrados and extrados curves (not visualized), n=2:

Successfully generated planar surface but incorrect

extrusion direction, n=3: Corrected extrusion vector

orientation, resulting in topologically and geometri-

cally valid 3D form.

Discussion. The experimen tal results demonstrate

iterative geometric refinement across successive gen-

erations, though convergence is not consistently

achieved for all test cases. The ball bearing example

exhibited systematic improvement in geometric accu-

racy and topological validity over 5 iteratio ns, pro-

gressing from a simplified cylindrical representation

to a complete mode l with prope r race profiles and

ball spacing . In contrast, the aircraft wing case high-

lighted po tential lim itations, requ iring only 3 iter a -

tions but encountering initial mathematical generation

failures before achieving a valid 3D form. These pre-

liminary findings, while promising, warrant further

validation across a broader range of mechanical com-

ponen ts to comprehensively assess the m ethodology’s

robustness and generalizability. The results also sug-

gest that targeted human intervention, through man-

ual augmentation of diagnostic feedback, may en-

hance convergence b y redirecting suboptimal initial

design choices. Additio nal experimentation is needed

to evaluate the approach’s scalability to more com-

plex geometries and to establish quantitative metrics

for convergence behavior.

6 CONCLUSION AND

PERSPECTIVES

This paper presented two scientific contributions en-

abling 3D geometry gener ation using Large Language

Models:

• A programmatic approach using a dedicated API

for geometry creation

• A closed-loop architecture for context augmen-

tation, termed Iterative Diagnosis-Driven Aug-

mented Generation (IDDAG)

This solution offers key a dvantages: without

requirin g extensive training or fine-tuning, it pro-

duces human-readable, explainable, and par ameter-

ized models that generate topologically valid geome-

tries. The 3D artifact gene ration maintains trace-

ability to requirements and refines throu gh itera-

tions. The proposed methodology has been imple-

mented and validated on elementary test cases. Short

term resear ch directio ns include formal analysis of

convergence proper ties and optimization of iteration

counts, mor e complex geometries and extension to

complex assemblies with multiple interacting compo-

nents. The diagnostic-driven augmentation approach

shows potential for transposition to oth er design do-

mains where systematic f eedback can be generated.

Mid to long-term researc h priorities include e stablish-

ing forma l co nvergence guaran te e s, evaluating sys-

MBSE-AI Integration 2025 - 2nd Workshop on Model-based System Engineering and Artificial Intelligence

478

Figure 2: Closed-loop architecture of the Iterative Diagnosis-Driven Augmented Generation (IDDAG) system.

Table 1: Ball Bearing: Geometric Evolution Across Iterations.

n = 1 n = 2 n = 3 n = 4 n = 5

Table 2: Aircraft Wing: Geometric Evolution Across Iterations.

n = 2 n = 3

tem scalability for complex assemblies, and develop-

ing r obust integration protocols with established CAD

workflows.

REFERENCES

Bourdin, M., Neumann, A., Paviot, T., Pellerin, R., and

Lamouri, S. ( 2024). Exploring the applications of

natural language processing and language models for

production, planning, and control activities of SMEs

in industry 4.0: a systematic literature review. Jour-

nal of Intelligent Manufacturing.

Liang, J. T., Yang, C., and Myers, B. A. (2024). A large-

scale survey on the usability of ai programming as-

sistants: Successes and challenges. In Proceedings of

the 46th IEEE/ACM International Conference on Soft-

ware Engineering.

Meussen, B. (2021). On the use of model based systems

engineering and CAD for the design of physical prod-

ucts. Proceedings of the Design Society, 1:2317–

2326.

Mortenson, M. E. (1997). Geometric modeling. John Wiley

& Sons, Inc.

Mun, D., Han, S., Kim, J., and Oh, Y. (2003). A

set of standard modeling commands for the history-

based parametric approach. Computer-Aided Design,

35(13):1171–1179.

Naveed, H., Khan, A. U., Qiu, S., Saqib, M., Anwar, S., Us-

man, M., Akhtar, N., Barnes, N., and Mian, A. (2024).

A comprehensive overview of large language models.

Paviot, T. (2022). pythonocc.

Wu, S., Khasahmadi, A., Katz, M., Jayaraman, P. K., Pu, Y.,

Willis, K., and Liu, B. (2023). CAD-LLM: Large lan-

guage model for CAD generation. In NeurIPS 2023

Workshop on Machine Learning for Creativity and

Design.

Xu, X., Lambourne, J., Jayaraman, P., Wang, Z., Willis, K.,

and Furukawa, Y. (2024). Brepgen: A b-rep genera-

tive diffusion model with structured latent geometry.

ACM Transactions on Graphics, 43(4).

Yuan, Z., Shi, J., and Huang, Y. (2024). OpenECAD: An

efficient visual language model for editable 3D-CAD

design. Computers & Graphics, 124.

Zhang, C., Pinqui´e, R., Polette, A., Carasi, G., De Char-

Iterative Diagnosis-Driven Augmented Generation (IDDAG) for Programmatic 3D CAD

479

nace, H., and Pernot, J.-P. (2023). Automatic 3D CAD

models reconstruction fr om 2D orthographic draw-

ings. Computers & Graphics, 114:179–189.

Zhang, C., Polette, A., Pinqui´e, R., Carasi, G., De Char-

nace, H., and Pernot, J.-P. (2024). eCAD-Net: Ed-

itable parametric CAD models reconstruction fr om

dumb B-Rep models using deep neural networks.

Computer-Aided Design, 178.

APPENDIX

1

from OCC . Core . BRep Build erAP I impor t

BRep Buil d erAP I_Mak e Po lygon ,

BRep Buil d erAP I_Mak eFace ,

BRep Buil d erAP I_Mak ePri sm

2

from OCC . Core . BRep PrimA PI imp ort

BRep Prim A PI_M akeCy lind er

3

from OCC . Core . BRep AlgoA PI imp ort

BRep Algo A PI_C ut

4

from OCC . Core . gp i m port gp_Pnt ,

gp_Vec , gp_Ax2 , gp _Dir

5

from OCC . Core . BRep Offse tAPI impo r t

BRep Offs e tAPI_Mak eThic kSolid

6

7

# Nut s p ecif icati ons

8

hex_ radi u s = 8.0 # Dist ance from

cent er to a flat , in mm

9

nut_ thic k ness = 8.0 # Thi cknes s of

the nut , in mm

10

thre ad_d i amet er = 10.0 # Diame ter

of the i nner thread , in mm

11

thre ad_c l eara n c e = 1.0 # Addi tiona l

clea ranc e for thre adin g

12

13

# Cre ate hex agona l base

14

hexa gon = BRe p Buil derAPI_Ma k e P o l yg o n

()

15

for i in r ange (6) :

16

angl e = i * (2 *

3.14 1592 6 5358 9793 / 6)

17

x = hex_r adius * math . cos ( ang le )

18

y = hex_r adius * math . sin ( ang le )

19

hexa gon . Add ( gp_P nt (x , y , 0) )

20

hexa gon . C lose ()

21

hex_ face = BRep B uild erAPI_ M akeF ace (

hexa gon . Wire () ). Face ()

22

23

# Ext rude to crea te the 3D he x agon al

pris m

24

extr usio n _vec = g p _Vec (0 , 0,

nut_ thic k ness )

25

hex_ pris m = BRepB uild e rAPI_ MakePri s m

( hex_face , e xtru sion_ vec ). S hape ()

26

27

# Cre ate cyl indri cal hole for

thre adin g

28

cyli nder = BRep P rimA PI_Make Cyli nder (

gp_A x2 ( g p _Pnt (0, 0 , 0) , g p_Dir (0 ,

0 , 1) ) , thre ad_di amet e r / 2 +

thre ad_c l eara nce , nu t_thi ckne s s ) .

Shap e ()

29

30

# Sub tract cylin der from hexag onal

pris m to form the nut body

31

nut = BRe p Algo API_C ut ( hex _pris m ,

cyli nder ) . Shape ()

MBSE-AI Integration 2025 - 2nd Workshop on Model-based System Engineering and Artificial Intelligence

480