Modeling and Simulation of Ethanol Steam Reforming for

Sustainable Hydrogen Production

Luca Cimmino

a

, Francesco Calise

b

, Francesco Liberato Cappiello

c

,

Massimo Dentice d’Accadia

d

and Maria Vicidomini

e

Department of Industrial Engineering, University of Naples Federico II, Piazzale V. Tecchio 80, 80125, Napoli, Italy

Keywords: Ethanol Reforming, Hydrogen Production, Sustainable Energy, Reactor Modeling, Energy Transition.

Abstract: The transition toward sustainable energy systems emphasizes hydrogen as a clean energy carrier, with ethanol

steam reforming emerging as a promising pathway for its renewable production. This study presents a one-

dimensional reactor model developed and simulated using MatLab, integrating thermodynamic, kinetic, and

heat transfer analyses to evaluate the performance of ethanol reforming. The model was validated against

existing literature and simulated under varying operational parameters. Key numerical results indicate that

the reactor achieves a hydrogen yield of 85% and an energy efficiency exceeding 75% at optimal conditions,

with inlet temperatures of 600°C and an ethanol-to-water molar ratio of 1:3. Sensitivity analysis revealed that

increasing the ethanol flow rate from 0.1 to 0.3 mol/s reduced the hydrogen yield by 12%, while adjusting the

reactor diameter from 0.05 m to 0.1 m improved the thermal efficiency by 10%. The system performance was

also significantly influenced by heat transfer coefficients, which ranged from 500 to 800 W/m²·K along the

reactor. The study also highlights the potential of integrating carbon capture technologies to mitigate CO

2

emissions generated as a byproduct. These findings provide valuable insights for optimizing ethanol

reforming reactors, paving the way for scalable and sustainable hydrogen production technologies in

renewable energy systems.

1 INTRODUCTION

The increasing urgency of addressing global climate

change has intensified the search for sustainable

energy solutions to reduce reliance on fossil fuels.

Hydrogen, as a clean energy carrier, has emerged as

a cornerstone of the global transition toward low-

carbon energy systems due to its versatility and

environmental benefits (Kovač, 2021). Among

various hydrogen production technologies, ethanol

steam reforming stands out as a renewable and

scalable method that leverages biomass-derived

ethanol, aligning with global sustainability goals (Ni,

2007).

Ethanol steam reforming involves complex

chemical and physical processes, including

endothermic reactions, heat transfer, and intricate

a

https://orcid.org/0000-0001-6382-3619

b

https://orcid.org/0000-0002-5313-7592

c

https://orcid.org/0000-0001-6292-686X

d

https://orcid.org/0000-0002-6766-5029

e

https://orcid.org/0000-0003-2827-5092

kinetic mechanisms, which present significant

modeling and optimization challenges (Palma,

2014).

Kinetic modeling plays a crucial role in

understanding the chemical reaction rates involved in

ethanol steam reforming (ESR). Various studies have

proposed kinetic models utilizing mechanisms such

as Eley-Rideal (ER) (Zhang, 2014) and Langmuir –

Hinshelwood – Hougen - Watson (LHHW)

(Olafadehan, 2015), which describe the interactions

between reactants, intermediates, and catalysts while

identifying the rate-determining steps (RDS)

governing the overall reaction. The ER mechanism

involves the reaction of a gas-phase molecule with an

adsorbed species on the catalyst surface. For ESR,

this is represented by a gas-phase species reacting

directly with an adsorbed molecule to form products.

232

Cimmino, L., Calise, F., Cappiello, F. L., Dentice d’Accadia, M. and Vicidomini, M.

Modeling and Simulation of Ethanol Steam Reforming for Sustainable Hydrogen Production.

DOI: 10.5220/0013465000003953

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 14th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2025), pages 232-238

ISBN: 978-989-758-751-1; ISSN: 2184-4968

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

Akande et al. developed a kinetic model for

hydrogen production over a Ni-Al₂O₃ catalyst based

on this mechanism. They identified the dissociation

of adsorbed ethanol as the RDS, with reaction rates

evaluated using Levenberg-Marquardt regression.

Their model demonstrated a mean absolute deviation

of 21% and provided critical kinetic parameters to

optimize reactor performance (Akande, 2006).

The LHHW mechanism, in contrast, involves

the adsorption of both reactants on the catalyst

surface, followed by surface reactions to form

products. This mechanism is mathematically

described by equations accounting for adsorption,

surface reactions, and desorption steps. Akpan et al.

extended the LHHW model for ESR using a Ni-based

catalyst, demonstrating the absence of methane and

carbon monoxide in the effluent at operational

temperatures between 673 and 863 K. Their work

highlighted the significance of dehydrogenation,

dehydration, and C-C bond cleavage reactions in the

reforming process (Akpan, 2007).

Mas et al. developed two LHHW-based models for

ESR using Ni-Al/OH catalysts, considering both

ethanol and methane reforming reactions. Their

Model A ignored CO and CO

2

adsorption, while

Model B included methane adsorption as a

competitive step. They identified the surface reaction

between ethanol and water as the RDS, with

activation energies ranging from 145 to 213 kJ/mol

(Mas, 2008).

Similarly, Sahoo et al. investigated ESR on

Co/Al₂O₃ catalysts, focusing on acetaldehyde

formation as the RDS. Their study demonstrated

nearly 100% ethanol conversion and hydrogen yields

of 5 mol/mol ethanol at 973 K (Sahoo, 2007).

Graschinsky et al. proposed a LHHW model for

ESR using a Rh/MgAl₂O₄-Al₂O₃ catalysts,

emphasizing the interplay between ethanol

dissociation, water-gas shift reactions, and methane

reforming. Their experiments achieved 83%

conversion at 873 K and revealed significant insights

into the role of surface reactions in hydrogen

production (Graschinsky, 2010).

Punase et al. advanced the field by applying a

multi-objective optimization approach to ESR

reactors, balancing hydrogen yield and thermal

efficiency. Using a model based on Mas et al.'s

framework, they identified optimal operating

conditions through advanced numerical algorithms.

Their findings underscored the importance of

operational parameters, such as temperature,

pressure, and the steam-to-ethanol ratio, in

maximizing reactor performance (Punase, 2019).

Despite these advances, challenges remain in

integrating kinetic models with practical reactor

simulations. Most studies assume idealized

conditions, neglecting heat and mass transfer

phenomena that significantly affect reactor

performance. Moreover, the competitive adsorption

of intermediates and byproducts introduces additional

complexities, necessitating further experimental

validation and model refinement to improve the

accuracy of simulations.

Accurate modeling of these processes is critical

to optimizing reactor performance and achieving the

efficiency required for commercial viability. While

existing studies have made considerable strides in

modeling ethanol reforming reactors (Punase, 2019),

most focus on either thermodynamic or kinetic

aspects, often neglecting their integration with heat

transfer and practical operational conditions (Mas,

2008). Furthermore, limited sensitivity analyses are

available to evaluate the impact of varying

operational parameters on hydrogen yield and

thermal efficiency (Olafadehan, 2015).

This study addresses these gaps by developing a

one-dimensional reactor model for ethanol steam

reforming that integrates thermodynamics, kinetics,

and heat transfer considerations. Implemented in

MatLab, the model advances existing research by

evaluating the reactor performance under realistic

operating conditions and conducting a

comprehensive sensitivity analysis. Key innovations

include the incorporation of heat transfer coefficients

along the reactor length and the identification of

optimal operating parameters, such as ethanol flow

rate, reactor dimensions, and inlet temperatures.

These improvements provide a more robust

framework for optimizing hydrogen production while

minimizing energy consumption and environmental

impact.

The outcomes of this work contribute

significantly to the ongoing development of

sustainable hydrogen production technologies. By

addressing the complexities of ethanol reforming and

bridging gaps in the literature, this study offers

actionable insights for scaling up ethanol-based

hydrogen systems as a viable alternative in the global

energy transition.

2 METHODOLOGY

The methodology adopted in this study follows a

structured and systematic approach. Initially, the

theoretical foundations of ethanol reforming

chemistry and the thermodynamics governing heat

Modeling and Simulation of Ethanol Steam Reforming for Sustainable Hydrogen Production

233

exchange phenomena were thoroughly reviewed,

with a focus on identifying the most robust and

widely recognized models in the scientific literature.

Subsequently, these models were individually

developed and implemented in MatLab environment

to verify the accurate behavior and performance of

the one-dimensional (1D) field. Following this, the

models were integrated to simulate the performance

of an ethanol reforming reactor under varying

operating conditions, providing insights for its

potential integration into a more comprehensive

dynamic model.

Finally, sensitivity analyses were conducted to

assess the system dependence on various variables

and operating parameters, highlighting key factors

that influence reactor performance.

3 MODEL

This section describes the model used to simulate

ethanol reforming within the reformer component.

The model integrates concepts of thermodynamics,

chemical kinetics, and reactor engineering. Various

approaches and methodologies were employed to

develop an accurate and efficient model for hydrogen

production via ethanol reforming.

3.1 Heat Transfer Model

The reactor was modeled as a concentric tube heat

exchanger in equi-current configuration.

The global heat transfer coefficient (U) is a key

parameter in determining the efficiency of the heat

exchanger. It is calculated considering both

convective and conductive thermal resistances:

11 1

wall

int wall ext

t

Uh k h

=+ +

(1)

where h

int

and h

ext

are the convective heat transfer

coefficients for the inner and annular fluids,

respectively, t

wall

is the wall thickness of the inner

tube, and k

wall

is the thermal conductivity of the tube

material.

Calculating U is crucial to assess the efficiency of

heat exchange between two slices in the reactor

model. To calculate U, it is necessary to determine the

properties of the two fluids: a hot fluid (a mixture of

nitrogen and oxygen resulting from post-combustion

in a Solid Oxide Fuel Cell, (SOFC) and a fuel mixture

(a combination of nitrogen, ethanol, and water vapor).

The calculated properties include dynamic viscosity

(interpolated from NIST tables, in case of pure

components, while for ethanol, values are obtained

from REFPROP), thermal conductivity, gas density,

fluid velocity, dimensionless convective flow

numbers (Re, Pr, Nu).

3.1.1 Thermal Energy Balance

The energy balance for a concentric tube heat

exchanger equates the heat released by the hot fluid

to the heat absorbed by the cold fluid:

()()

,, , ,, ,h p h h in h out c p c c out c in

QmC T T mC T T=−= −

(2)

Where Q is the heat transferred, ṁ

h

and ṁ

c

are the

mass flow rates of the hot and cold fluids,

respectively, c

p,h

and c

p,c

are the specific heat

capacities of the hot and cold fluids, respectively, T

h,in

and T

h,out

are the inlet and outlet temperatures of the

hot fluid, respectively, and T

c,in

and T

c,out

are the inlet

and outlet temperatures of the cold fluid.

The heat transfer balance is coupled with the Log

Mean Temperature Difference (LMTD), representing

the driving force for heat transfer in the heat

exchanger (Bergman, 2011).

The efficiency of a concentric tube heat exchanger

is given by:

max

Q

Q

η

=

(3)

Where Q is the actual heat transferred and Q

max

is

the maximum theoretically transferable heat

(Bergman, 2011).

3.2 Ethanol Reforming Model

The ethanol steam reforming process was modeled as

a one-dimensional plug flow reactor (PFR), assuming

that axial variations dominate over radial variations.

This approach is suitable for systems where gradients

in temperature, concentration, and velocity in the

radial direction are negligible.

The reactor was discretized into differential

control volumes, allowing for numerical integration

of the governing equations.

The assumptions and simplifications of the model

are as follows:

1. The system operates under steady-state

conditions.

2. Ideal gas behavior is assumed for all species.

3. Radial gradients in temperature and

concentration are negligible.

SMEN 2025 - Special Session on Smart City and Smart Energy Networks

234

4. Heat losses to the surroundings are ignored,

and only heat transfer between the catalyst

bed and the gas phase is considered.

5. The reaction rates are governed by kinetic

models based on the LHHW mechanism.

In ethanol reforming, the LHHW mechanism is

frequently used to model catalytic reactions. The key

reactions involved include:

• Ethanol decomposition:

C

2

H

5

OH → CH

3

CHO + H

2

(4)

• Steam reforming:

C

2

H

5

OH + H

2

O → 2CO + 4H

2

(5)

• Water-gas shift reaction:

CO + H

2

O → CO

2

+ H

2

(6)

The kinetic equations for these reactions account for

the adsorption of reactants, surface reactions, and

desorption of products. For example, the reaction rate

(r) for ethanol steam reforming can be expressed as:

()

25 2

25 25 2 2

2

1...

reac C H OH H O

CHOH CHOH E HO HO

k

r

KPKKP

θθ

=

+++

(7)

where k

reac

is the reaction rate constant, θ represents

the fraction of adsorption sites occupied by each

species, and K denotes the adsorption constants for

the reactants. This formulation captures the

competitive adsorption of reactants and the role of

catalyst surface phenomena in determining reaction

rates.

3.2.1 Chemical Kinetic Model

The kinetic model employed in this study is the

Model B described by Mas et al. (Mas, 2008). This

model adopts the LHHW approach to describe the

catalytic surface reactions involved in ethanol steam

reforming. The key reactions considered in this model

include:

• Adsorption of ethanol on the catalyst

surface:

C

2

H

5

OH+(a)↔C

2

H

5

OH∗

(8)

• Adsorption of water on the catalyst surface:

H

2

O+(a)↔H

2

O∗

(9)

• Surface reaction causing ethanol

dissociation:

C

2

H

5

OH∗→CO+CH

4

∗+H

2

(10)

• Surface reaction between water and ethanol:

C

2

H

5

OH∗+H

2

O∗→CO

2

+CH

4

∗+2H

2

+(a)

(11)

• Desorption of methane:

CH

4

∗↔CH

4

+(a)

(12)

• Surface reaction of methane and molecular

rearrangement of water:

CH

4

∗+H

2

O∗→CO+3H

2

+2(a)

CH

4

∗+2H

2

O∗→CO

2

+4H

2

+3(a)

(13)

The four rate-determining steps (RDS) in this

model are ethanol decomposition, ethanol steam

reforming, methane steam reforming-I, and methane

steam reforming-II.

The reaction rates (r

1

, r

2

, r

3

, and r

4

) are functions

of temperature and the concentrations of the

reactants. These rates are used to solve the differential

mass balance equations between slices of the reactor.

The rate equations for each reaction, along with the

standard heats of formation (ΔH

0

), are presented in

Table 1.

Table 1: Rate equations (Model B) and Standard Heats of

Formation.

Reaction Rate Equation

ΔH

0

(kJ/mol)

Ethanol

Decomposition

22

1

1

1

EE

E

EHOHOMM

kK P

r

PK P K P K

=

++ +

49.7

Ethanol Steam

Reforming

()

22

22

2

2

2

1

EHOEHO

EE HOHO MM

kK K PP

r

PK P K P K

=

++ +

205.0

Methane Steam

Reforming-I

()

22 2

22

4

33

3

2

1

MHOMHO COH

EE HOHO MM

kK K P P KP P

r

PK P K P K

−

=

++ +

206.1

Methane Steam

Reforming-II

()

22

22

2

4

4

3

1

MHOMHO

EE HOHO MM

kK K PP

r

PK P K P K

=

++ +

165.0

Where the subscript E refers to ethanol, k

i

is the

reaction rate constant and K

i

is the equilibrium

constant, for the i-th chemical species. Kinetic

parameters, such as rate constants and adsorption

coefficients, were taken from several studies. For the

implementation of this model, the parameters

proposed by K. D. Punase et al. (Punase, 2019) were

adopted, shown in Table 2.

Modeling and Simulation of Ethanol Steam Reforming for Sustainable Hydrogen Production

235

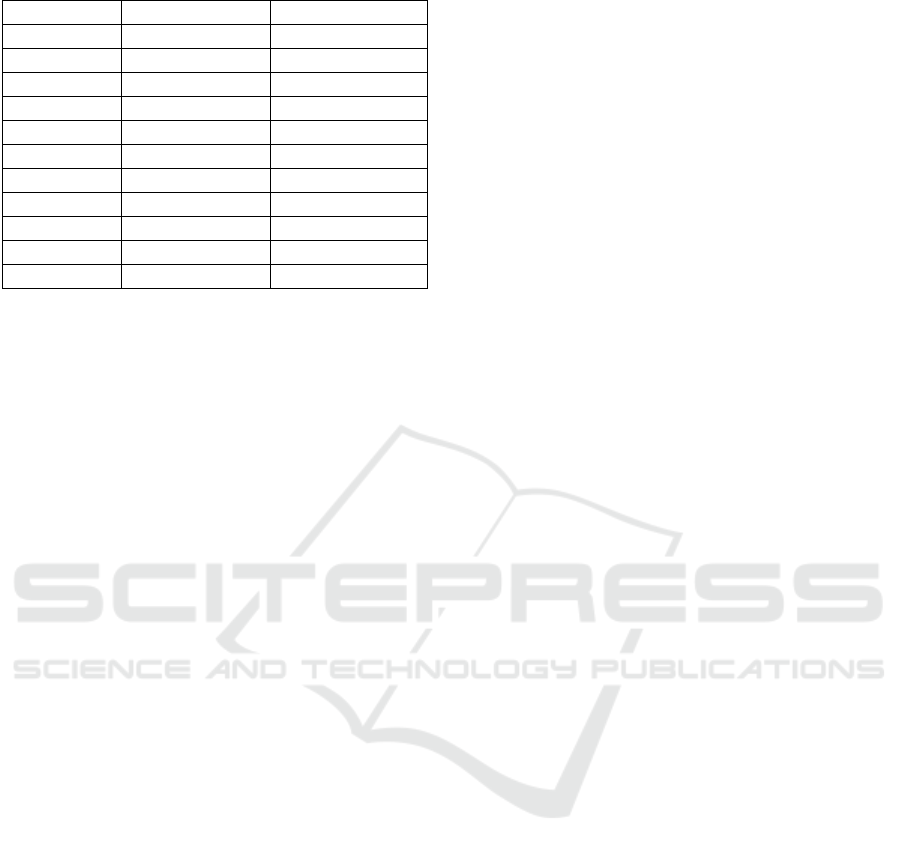

Table 2: Kinetic parameters adopted in this model.

Parameter Value Unit

k

1,0

3.27x10

11

mol/(min∙C

p

∙

g

ca

t

)

k

2,0

1.39x10

10

mol/(min∙C

p

∙

g

ca

t

)

k

3,0

2.21x10

3

mol/(min∙C

p

∙

g

ca

t

)

k

4,0

1.26x10

9

mol/(min∙C

p

∙

g

ca

t

)

E

a,1

271,902 J/mol

E

a,2

226,768 J/mol

E

a,3

123,279 J/mol

E

a,4

213,936 J/mol

ΔH

E

-197,964 J/mol

ΔH

H

2O

-91,708 J/mol

ΔH

M

-124,789 J/mol

3.2.2 Mass and Energy Balances

The mass balance in a plug flow reactor assumes one-

dimensional, pseudo-homogeneous, steady-state, and

isothermal conditions to model species changes via

differential equations accounting for reaction rates. For

non-ideal isothermal behavior, the reactor is divided

into slices where local isothermality is assumed.

Energy balances for each slice account for heat transfer

and reaction enthalpies, and an iterative solution

(implemented in MATLAB) across many slices

provides a detailed temperature and composition

profile for the ethanol reforming process.

3.3 Simulation Setup

The simulations were conducted by using reactor

parameters typical of lab-scale processes. Boundary

conditions were defined based on inlet flow rates and

temperatures, and the constants of the model are the

ones given from Punase et al. (Punase, 2019).

The reactor catalyst is a Ni/Al material with an

apparent density of 5.0 g/cm

3

and the reactor operates

at ambient pressure (1 atm). The reactor was

simulated under various operating conditions, with

key parameters summarized in (Punase, 2019).

The inlet temperature and pressure are 875 K for

the cold fluid and 1350 K for the hot fluid, and 1 atm

for both, respectively.

Ethanol, used as the carbon and hydrogen source,

is supplied at 15.00 kmol/h. A steam-to-ethanol (S/E)

ratio of 3.5 ensures an excess of steam, minimizing

solid carbon (coking) formation and enhancing

reaction efficiency (Mas, 2008).

Nitrogen at 30.0 kmol/h is included in the cold

fluid as an inert component, consistent with previous

studies. The cold fluid inlet temperature of 875 K falls

within the optimal range for reforming reactions

(Mas, Bergamini et al. 2008).

The hot fluid composition primarily consists of

nitrogen (210.1 kmol/h) and oxygen (20.9 kmol/h),

along with a negligible fraction of steam and carbon

dioxide from combustion. The inlet temperature of

1350 K reflects typical exhaust gas conditions from

SOFC systems, providing a nitrogen-rich stream

(from air used as an oxidant) with residual oxygen.

The model was validated against published

experimental data

from (Mas, 2008) to ensure accuracy.

4 RESULTS AND DISCUSSION

This section presents the results of the simulations

performed with the coupled chemical-heat transfer

model, discussing the key findings.

4.1 Results of the Simulation

Figure 1 shows the temperature trends of the hot and

cold fluids along the reactor, comparing scenarios of

pure heat exchange and heat exchange coupled with

chemical reactions. The comparison was conducted

using the same model, but in one case excluding

chemical reactions and the associated heat

consumption from the energy balances. This analysis

aimed to evaluate the impact of chemical reactions on

temperature profiles.

The graph shows that, as expected, the cold fluid

temperature reaches higher values when reactions are

not considered. Without the heat consumption

required for endothermic reactions, all heat

transferred from the hot fluid is utilized solely to

increase the cold fluid temperature.

Figure 2 shows the heat transfer coefficient along

the reactor. This coefficient reflects the efficiency of

heat transfer from the hot fluid to the cold fluid and

varies along the reactor, influenced by local

temperature conditions and fluid composition.

The graph displays the variation of the heat

transfer coefficient (U) along the reactor. Despite the

decreasing temperature difference between the two

fluids, the heat transfer coefficient increases. This

behavior can be explained by specific factors in the

one-dimensional discrete model:

• Improved Convection Conditions: Even as the

temperature difference decreases, the flow

conditions may enhance convection. This could

result from increased turbulence or improved

fluid velocity profiles, leading to more effective

heat transfer.

• Changes in Fluid Properties: The thermophysical

properties of the fluids, such as viscosity and

thermal conductivity, change with temperature.

SMEN 2025 - Special Session on Smart City and Smart Energy Networks

236

These variations may favour the heat transfer.

For example, reduced viscosity improves

convection, while increased thermal conductivity

enhances heat transfer capacity.

Figure 3 depicts the composition of the cold fluid

along the reactor, divided into reactants and products.

The concentration changes reflect the progression of

chemical reactions, showing a decrease in reactants

(ethanol and water) and an increase in products

(hydrogen, carbon monoxide, carbon dioxide,

methane) along the reactor length.

Figure 1: Temperatures of hot and cold fluids along the

reactor with and without reactions.

Figure 2: Heat transfer coefficient along the reactor.

As observed in the graph, ethanol conversion

results are not close to optimal values. This is

influenced by the initial parameter selection and heat

exchanger configuration, which affect:

• Cold Fluid Velocity: It must remain low to

ensure sufficient residence time for ethanol in the

reactor but cannot be too low, as this would

compromise heat transfer.

• Reactor Volume and Catalyst Quantity: These

determine the extent of reaction and conversion

rates.

• Initial Composition of the Cold Fluid: This

impacts reactant concentrations and,

consequently, reaction rates.

Figure 3: Composition of the cold fluid along the reactor.

5 CONCLUSIONS

This study confirms the potential of ethanol steam

reforming as a sustainable pathway for hydrogen

production, underlining its significance in advancing

clean energy technologies. The integrated reactor

model, encompassing thermodynamic, kinetic, and

heat transfer analyses, was validated against literature

and applied under various operational conditions,

yielding valuable insights into reactor performance

and optimization.

The simulations revealed a hydrogen yield of 85%

and an energy efficiency exceeding 75% at optimal

conditions, specifically at an inlet temperature of

600°C and an ethanol-to-water molar ratio of 1:3.

Sensitivity analysis further highlighted the impact of

critical parameters. For instance, increasing the

ethanol inlet flow rate from 0.1 mol/s to 0.3 mol/s

resulted in a 12% reduction in hydrogen yield,

attributed to reduced residence times. Adjusting the

reactor diameter from 0.05 m to 0.1 m led to a 10%

improvement in thermal efficiency. The heat transfer

coefficients, varying between 500 and 800 W/m²·K

along the reactor, were shown to significantly

influence reactor efficiency.

Moreover, the study emphasized the role of the

heat exchange area-to-geometric area ratio in

optimizing the process. Enhancements in this ratio,

achieved through technological adjustments like fins,

substantially improved hydrogen production and

ethanol conversion.

In conclusion, the developed model offers a robust

framework for designing and optimizing ethanol

reforming reactors. The findings not only deepen the

understanding of reaction mechanisms and heat

transfer dynamics but also provide actionable strate-

gies for scaling up hydrogen production technologies

while supporting the global energy transition.

Modeling and Simulation of Ethanol Steam Reforming for Sustainable Hydrogen Production

237

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the partial

financial support of the project PRIN 2020:

OPTIMISM – Optimal refurbishment design and

management of small energy micro-grids, funded by

the Italian Ministry of University and Research

(MUR).

REFERENCES

Akande, P., Rao, Vijay (2006). "A review on mechanistic

kinetic models of ethanol steam reforming for hydrogen

production using a fixed bed reactor." Chemical Papers

73: 1027-1042.

Akpan, E., A. Akande, A. Aboudheir, H. Ibrahim and R.

Idem (2007). "Experimental, kinetic and 2-D reactor

modeling for simulation of the production of hydrogen

by the catalytic reforming of concentrated crude ethanol

(CRCCE) over a Ni-based commercial catalyst in a

packed-bed tubular reactor." Chemical Engineering

Science 62(12): 3112-3126.

Bergman, T. L., A. S. Lavine and F. P. Incropera (2011).

Fundamentals of Heat and Mass Transfer, 7th Edition,

John Wiley & Sons, Incorporated.

Graschinsky, C., M. Laborde, N. Amadeo, A. Le Valant, N.

Bion, F. Epron and D. Duprez (2010). "Ethanol Steam

Reforming over Rh(1%)MgAl2O4/Al2O3: A Kinetic

Study." Industrial & Engineering Chemistry Research

49(24): 12383-12389.

Kovač, A., M. Paranos and D. Marciuš (2021). "Hydrogen

in energy transition: A review." International Journal

of Hydrogen Energy 46(16): 10016-10035.

Mas, V., M. L. Bergamini, G. Baronetti, N. Amadeo and M.

Laborde (2008). "A Kinetic Study of Ethanol Steam

Reforming Using a Nickel Based Catalyst." Topics in

Catalysis 51(1): 39-48.

Ni, M., D. Y. C. Leung and M. K. H. Leung (2007). "A

review on reforming bio-ethanol for hydrogen

production." International Journal of Hydrogen Energy

32(15): 3238-3247.

Olafadehan, O. A., A. Ayoola, O. Akintunde and V.

Adeniyi (2015). "Mechanistic Kinetic Models For

Steam Reforming Of Concentrated Crude Ethanol On

Ni/Al

2

O

3

Catalyst."

Palma, V., F. Castaldo, P. Ciambelli and G. Iaquaniello

(2014). "CeO2-supported Pt/Ni catalyst for the

renewable and clean H2 production via ethanol steam

reforming." Applied Catalysis B: Environmental 145:

73-84.

Punase, K. D., N. Rao and P. Vijay (2019). "A review on

mechanistic kinetic models of ethanol steam reforming

for hydrogen production using a fixed bed reactor."

Chemical Papers 73(5): 1027-1042.

Sahoo, D. R., S. Vajpai, S. Patel and K. K. Pant (2007).

"Kinetic modeling of steam reforming of ethanol for the

production of hydrogen over Co/Al2O3 catalyst."

Chemical Engineering Journal 125(3): 139-147.

Zhang, C., S. Li, G. Wu, Z. Huang, Z. Han, T. Wang and J.

Gong (2014). "Steam reforming of ethanol over skeletal

Ni-based catalysts: A temperature programmed

desorption and kinetic study." AIChE Journal 60(2):

635-644.

SMEN 2025 - Special Session on Smart City and Smart Energy Networks

238