The Future of BPM in the Era of Industry 4.0: Exploring New

Opportunities for Innovation

Hadjer Khider

1,2

, Abdelkrim Meziane

2

and Slimane Hammoudi

3

1

Information Systems and Multimedia Systems Department, CERIST, Algiers, Algeria

2

Computer Science Department, Abderrahman Mira University, Bejaia, Algeria

3

MODESTE Team, Computer Science Department – ESEO, Angers, France

Keywords: Business Process Management (BPM), Industry 4.0, Digital Transformation, Digitalization, SLR.

Abstract: In today's digital age, the fourth industrial revolution has given rise to Industry 4.0. This new paradigm has

brought new challenges for organizations, through a digital transformation. This digital transformation has

profoundly impacted the way businesses operate, leading to a fundamental shift in the Business Process

Management (BPM), affecting business models, processes, products, relationships and competencies. This

transformation is based on the use of cyber-physical systems and information and communication

technologies, in particular artificial intelligence and the Internet of Things. This paper aims to identify and

define the main challenges, limitations, and opportunities of BPM in the era of Industry 4.0. Furthermore, it

aims to identify potential future research directions. in addition to analyzing the impact of Industry 4.0

concepts and related technologies on the management of organizations and their business processes.

1 INTRODUCTION

The advent of contemporary technological advances

has led to the emergence of Industry 4.0, which can

be regarded as a consequence of the Fourth Industrial

Revolution (Xu, Xu, et Li 2018). This new paradigm

has brought changes in the functioning of the

organization through a digital transformation

affecting business models, processes, products and

skills (Flechsig et al. 2022). In the current business

environment, characterized by intense competition, a

fail-fast culture is imperative for organizations to

succeed (Szelągowski et Berniak-Woźny 2022).

Organizations are integrating digital technologies

into their core business processes to enhance

efficiency, improve customer experience, and drive

innovation (Vaska et al. 2021). In the era of Industry

4.0, organizations are confronted with complex

implementation issues surrounding the digital

transformation. These issues include the adoption of

new Cyber-Physical Systems (CPS) and smart factory

technologies as the Internet of Things (IoT), Artificial

Intelligence (AI), and data analytics, as well as the

adaptation or replacement of core Enterprise

Architectures (EA), Communication Technologies

(ICT) infrastructures and processes (Xu, Xu, et Li

2018).

Unfortunately, many organizations lack the

necessary capabilities to effectively address these

issues (Di Ciccio, Marrella, et Russo 2015;

Szelągowski et Berniak-Woźny 2022).

Consequently, these organizations are carrying out

such transformation to adapt to the emerging

paradigm. This shift has led to the need for efficient

and effective BPM.

The transition from traditional industrial

ecosystems to Industry 4.0 will require not only the

development of new Information and ICT but also the

creation of new business models; The advent of

digitalization has profoundly impacted the way

businesses operate, leading to a fundamental shift in

the management of business processes (Colombo,

Schleuter, et Kircher 2015; Arnold, Kiel, et Voigt

2016). In this context, business process management

(BPM) plays a crucial role in supporting

organizations to achieve greater flexibility and

responsiveness (Grisold et al. 2021). It presents a

valuable and an advantageous tool through cost

reduction, process excellence, and continuous

process improvement, enabling organizations to

design, analyze, execute, monitor and optimize

important processes (Gartner 2018).

Khider, H., Meziane, A. and Hammoudi, S.

The Future of BPM in the Era of Industry 4.0: Exploring New Opportunities for Innovation.

DOI: 10.5220/0013477300003929

In Proceedings of the 27th International Conference on Enterprise Information Systems (ICEIS 2025) - Volume 2, pages 915-924

ISBN: 978-989-758-749-8; ISSN: 2184-4992

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

915

According to Gartner in (Gartner 2018), BPM is

critical for the success of business transformation

initiatives. BPM can deliver this level of agility to

business operations in combination with other

disciplines, such as EA (Gartner 2016).

Furthermore, BPM plays a crucial role in helping

organizations identify and optimize their key business

processes. It enables organizations to quickly adapt to

changing business environments, including humans,

applications, and technology (Liu, Chen, et Chou

2011). Ultimately, this leads to improved operational

efficiency and increased competitiveness (Gartner

2018; Viriyasitavat et al. 2019; Baiyere, Salmela, et

Tapanainen 2020; Butt 2020; Szelągowski et

Berniak-Woźny 2022).

In alignment with the aforementioned concepts,

this paper discusses the BPM limitations,

opportunities, and challenges in the era of Industry

4.0 and provides insights into how organizations can

leverage BPM to improve their operational

efficiency, customer experience, innovation, and

competitiveness. Additionally, the paper aims to

identify potential future research directions and

analyze the impact of Industry 4.0 concepts and

related technologies on the management of

organizations and their business processes.

The remainder of this paper is organized as

follows: Section 2 provides a theoretical overview of

the fundamental concepts related to this study, basing

on an analysis of existing literature. Section 3

presents the challenges associated with Industry 4.0.

Section 4 offers a comprehensive overview of BPM.

Section 5 presents a systematic literature review

(SLR) on BPM in the era of Industry 4.0. Section 6

explores the opportunities that Industry 4.0 presents

for BPM. Finally, Section 7 concludes with an

analysis of the findings, and outlines potential future

research directions.

2 THEORETICAL

BACKGROUND

The fourth industrial revolution, commonly referred

to as Industry 4.0, represents a significant shift in the

way industries operate, driven by the convergence of

digitalization, digital transformation, and emerging

technologies (Gajšek and Vujica Herzog 2020). This

section aims to introduce these foundational concepts,

providing a comprehensive understanding of their

interrelationships and implications for modern

industry.

2.1 Digitalization

Digitization is the process of encoding analog

information into digital formats enabling computers

to store processes, and transmit such information

effectively. In contrast, digitalization describes how

to use digital technology to change existing business

processes” (Lee et al. 2021). According to Berlak et

al. in (Berlak, Hafner, et Kuppelwieser 2021),

digitalization involves optimizing existing business

processes through enhanced integration and

coordinated collaboration, in order to facilitate the

creation of new business opportunities.

2.2 Digital Transformation

Digital Transformation is the further stage after

digitalization, describing the successful upgrade and

change that leads to a new business model (Lee et al.

2021). It can be defined as the process of integrating

digital technologies and business processes within a

digital economy. This transformation focuses on

the

restructuring business operations to fully facilitating

the use of a company's core competencies through

digital technology to achieve a competitive advantage

(Liu, Chen, et Chou 2011). In the context of BPM,

digital transformation refers to the transformation of

business operations, services and models. This

comprehensive transformation covers all processes

within the enterprise, ultimately to building a digital

model of the enterprise, incorporating digitized

process attributes (Tupa et Steiner 2019).

2.3 Industry 4.0

The term “Industry 4.0” was first introduced in 2011

at the Hannover Fair in Germany (Adolph et al.

2016). This concept, often referred to as the Fourth

Industrial Revolution, has emerged in the

manufacturing industry (Xu, Xu, et Li 2018).

Implementing Industry 4.0 involves a

number of

different technologies and techniques, including CPS,

IoT, cloud computing, blockchain, industrial

information integration and other related

technologies (Xu, Xu, et Li 2018). Industry 4.0 is

often described as

the Era of Intelligence, which

integrates information technology and operational

technology to achieve intelligence in a mass

customization paradigm, introducing technologies

such as the Internet of IoT, big data, AI, CPS, and

robotics into the factory environment (Guo et al.

2024).

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

916

3 INDUSTRY 4.0 CHALLENGES

The rapid evolution of Industry 4.0 technologies has

transformed the landscape of modern industry,

creating exceptional opportunities

for innovation and

efficiency. However, organizations often face a

variety of challenges that can hinder the successful

implementation and integration of these advanced

technologies (Gažová, Papulová, et Smolka 2022).

Key challenges include usability (Zhang et al., 2020),

computational efficiency (Yang, Q. et al. 2019),

scalability (Bai et al., 2020), interoperability, and

storage capacity (Su et al. 2023). The implementation

of advanced technologies also introduces potential

risks that organizations must carefully manage,

including cyber security threats, data privacy

concerns, and the possibility of significant

disruptions during the transition phase (Almubarak et

al., 2020). The Industry 4.0 approach relies on the

deployment of intelligent, interconnected Cyber-

Physical Systems (CPS), which presents significant

security challenges. Many of these systems were not

originally designed with cyber security

considerations, making cyber security a critical

concern for organizations adopting the Industry 4.0

paradigm (Corallo, Lazoi, et Lezzi 2020). Another

significant challenge of Industry 4.0 is its insufficient

focus on human-centricity and system resilience

.(Guo

et al. 2024). Additionally, the integration of AI, IoT,

and Blockchain within BPM introduces several

challenges, including developing business process

collaboration, managing large data volumes,

implementing smart contracts, ensuring

interoperability with Blockchain technology,

achieving standardization, and addressing security

and privacy concerns

. (Viriyasitavat et al. 2018).

Currently, the management of Business processes in

industry 4.0 faces significant challenges, including

centralization, lack of verifiability, trust issues, and

insufficient automation (Stefanescu, D. et al., 2024).

This context highlights the importance of smart

contracts, which can address these shortcomings by

providing a more decentralized and automated

approach to BPM.

4 BUSINESS PROCESS

MANAGEMENT

Business Process Management (BPM) is the

combination of knowledge from business

administration and information technology, applied

to operational business processes (Weske 2019). In

practice, BPM is the application of methods,

techniques, and software to design, enact, control, and

analyze operational processes that involve humans,

organizations, applications, documents, and other

sources of information (van der Aalst, ter Hofstede, et

Weske 2003; Di Ciccio, Marrella, et Russo 2015).

The emergence of Industry 4.0 has brought new

challenges for organizations requiring them to

address the complexities of implementing the latest

Industry 4.0 technologies (Colombo, Schleuter, et

Kircher 2015; Arnold, Kiel, et Voigt 2016). In the

current digital era, it is imperative that established

BPM tools are adapted in order to align with the

evolving needs of enterprises (Viriyasitavat et al.,

2019). This involves not only the integration of novel

technologies but also the creation of new business

models and the adaptation or even replacement of

existing core EA, ICT infrastructures and business

processes (Xu, Xu, et Li 2018).

5 BPM IN THE AGE OF

INDUSTRY 4.0: A SYSTEMATIC

LITERATURE REVIEW

Many studies emphasize the critical role of BPM in

driving digital transformation and enhancing

operational efficiency in industry 4.0. While BPM

presents opportunities for industry 4.0, it also faces

significant limitations and challenges in this new era.

This section outlines a study focused on identifying

these challenges and exploring potential solutions. A

systematic literature review (SLR) of academic

research on Industry 4.0 and BPM was conducted to

analyze existing limitations and challenges, as well as

to identify potential opportunities for overcoming

them.

5.1 Methodology

This research employs a systematic literature review

approach, aligned with PRISIMA guidelines (Moher

et al. 2010), and comprises seven phases:

Phase 1: involved searching for articles in the

Science direct, IEEE, and ACM. using keywords,

("business process management" OR "BPM") AND

("challenges" OR "limitations" OR "opportunities")

AND (“Industry 4.0”) to focus on BPM related

challenges, limitations and opportunities.

Phase 2: excluded publications prior to 2015,

ensuring the inclusion of literature, by targeting

articles published between 2015 and 2025.

Phase 3: selected articles by subject area, including

manufacturing, Business, Management and

Accounting, Engineering, Computer Sciences,

Decision Sciences.

The Future of BPM in the Era of Industry 4.0: Exploring New Opportunities for Innovation

917

Phase 4: excluded no English publications.

Phase 5: exclusion of papers according to article type,

research and review papers only.

Phase 6: retained journals ranked in the top two

quartiles (Q1 and Q2) of the SCImago database

Phase 7: involves evaluation of the titles and

abstracts based on the paper's coverage of the

opportunities, challenges or limitations of BPM

and/or proposals for future BPM improvements.

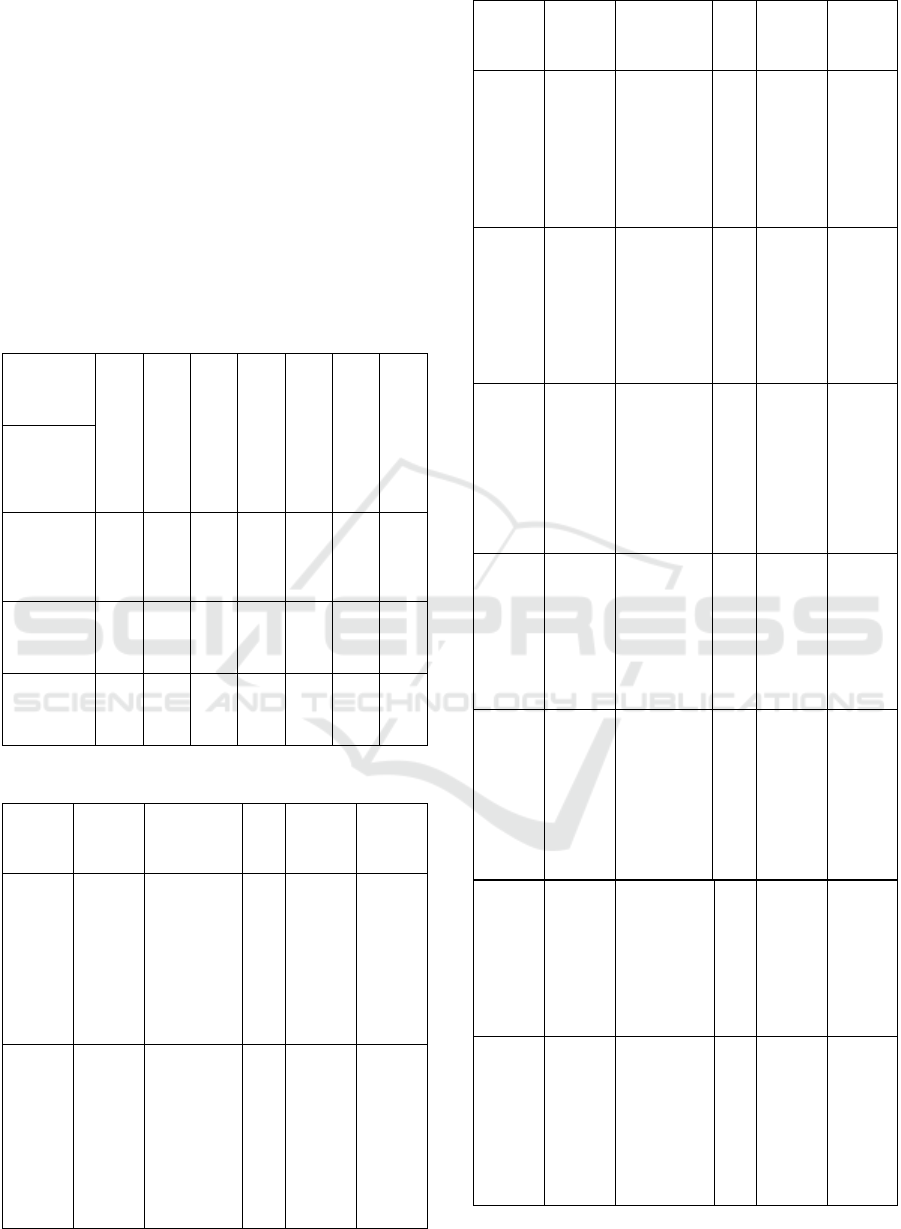

This analysis resulted in 22 selected papers

summarized in Table 1 and selected papers are

detailed in Table 2.

Table 1: Number of works published in the Science direct,

IEEE and ACM in the period 2015-2025.

Phases

Phase 01

phase 02

Phase 03

Phase 04

Phase 05

Phase 06

Phase 07

Database

Science

Direct/

Elsevier

4268

2571

2130

2127

1853

1168

13

IEEE

2848

1212

1121

1118

129

76

6

ACM

3571

1389

988

988

122

88

3

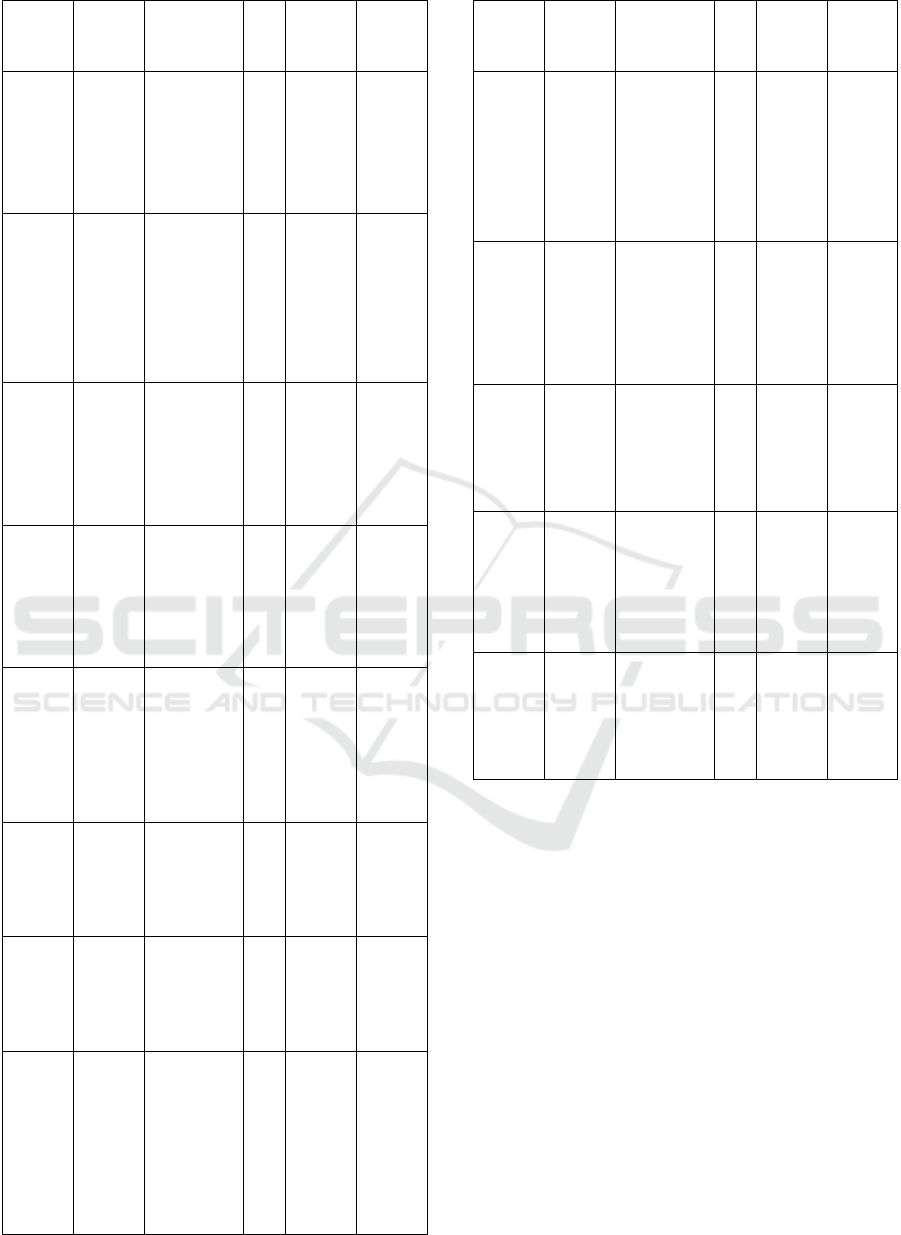

Table 2: Selected paper according to the paper's coverage.

Science direct

(Czvetkó et al. 2022)

Data-driven business process

management-based

development of Industry 4.0

solutions

CIRP Journal of Manufacturing

Science and Technology

Q1

24

Science direct

Schulte et al. 2015)

Elastic Business Process

Management: State of the art

and open challenges for BPM in

the cloud

Future Generation Computer

Systems

Q1

96

Database

Authors

Title

Journal

Title

Journal

quality

assessment

score

Citation

Science direct

(Guo et al. 2024)

Industrial metaverse towards

Industry 5.0: Connotation,

architecture, enablers, and

challenges

Journal of Manufacturing

Systems

Q1

6

Science direct

(Su et al. 2023)

Technical challenges of Blockchain

technology for sustainable

manufacturing paradigm in

Industry 4.0 era using a fuzzy

decision support system

Technological Forecasting &

Social Change

Q1

58

Database

Authors

Title

Journal

Title

Journal

quality

assessment

score

Citation

Science direct

(Saraeian, Shirazi, et

Motameni 2018)

Towards an extended BPMS

prototype: Open challenges

of BPM to flexible and robust

orchestrate of uncertain

processes

Computer Standards &

Interfaces

Q1

19

Science direct

(Souifi et al. 2022)

Uncertainty of key

performance indicators for

Industry 4.0: A methodology

based on the theory of belief

functions

Computers in Industry

Q1

14

Science direct

(Kamble, S. S., Gunasekaran,

A., Ghadge, A., & Raut, R.

2020)

performance measurement

system for industry 4.0 enabled

smart manufacturing system in

SMMEs-A review and empirical

investigation

. International journal of

production economics

Q1

705

Science direct

(Bai, C. et al. ,2020)

Industry 4.0 technologies

assessment: A sustainability

perspective

International Journal of

Production Economics

Q1

847

Science direct

(Van Looy 2021)

a quantitative and qualitative

study of the link between

business process management

and digital innovation

Information & Management

Q1

77

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

918

Database

Authors

Title

Journal

Title

Journal

quality

assessment

score

Citation

Science direct

(Pourmirza et al. 2017)

A systematic literature

review on the architecture

of business process

management systems

Information Systems

journal

Q1

44

Science direct

(Elghaish et al. 2021)

Blockchain and the ‘ Internet of

Things' for the construction

industry: research trends and

opportunities

Automation in Construction

Q1

127

IEEE

(Viriyasitavat et al. 2019)

Blockchain and Internet of

Things for Modern

Business Process in

Digital Economy

IEEE Transactions on

Computational Social

Q1

118

Science direct

(Arnold, Kiel, et Voigt

2016)

How Industry 4.0 changes

business models in

different manufacturing

industries

International Journal of

Innovation Management

Q2

252

Science direct

(Baiyere, Salmela, et

Tapanainen 2020)

Digital Transformation and

the New Logics of Business

Process Management

European Journal of

Information Systems

Q1

551

IEEE

(S. Moreira, et al,

2024)

Business Process

Automation in

SMEs: A Systematic

Literature Review

IEEE Access

Q1

3

Elsevier

(Nozari,

H.,&Ghahremani-

Nahr, l. .2024)

AI and machine

learning for real-

world problems.

In Advances In

Computers

Not assigned yet

67

IEEE

(Garcia-Garcia, etal .,2020)

Using Blockchain to Improve

Collaborative Business Process

Management: Systematic

Literature Review

IEEE Access

Q1

82

Database

Authors

Title

Journal

Title

Journal

quality

assessment

score

Citation

IEEE

(Bartlett, L., et al.,2023).

A review on business process

management system design: the

role of virtualization and work

design.

IEEE Access

Q1

5

IEEE

(Ahmed S. and Shahzad

K., 2022).

Augmenting Business

Process Model Elements

with End-User Feedback

IEEE Access

Q1

5

IEEE

(Cardoso P. B., et al.,

2024)

A Granular Risk

Analysis Approach for

IoT-Aware Business

Processes

IEEE Access

Q1

1

ACM

(Stefanescu, D. et

al.,2024)

Smart Contract Powered

Framework for the Next

Generation Industry 4.0

Business Model

Distributed Ledger

Technologies: Research

Note assigned yet

1

ACM

(Yang, Q. et al. 2019)

Federated machine

learning: Concept and

applications.

ACM Transactions on

Intelligent Systems and

Q1

7079

5.2 Findings

This section analyzes the findings on the

opportunities, challenges and limitations of current

BPM, along with recommended future directions.

The analysis is based on the analysis of 22 selected

documents listed in Table 2.

5.2.1 BPM Opportunities for Industry 4.0

In the Industry 4.0 era, improving business processes

provides new opportunities for organizational

transformation, including the redesign of business

models and value chains (Gancarczyk et Ujwary-Gil

2020), it establishes new alliances with IT,

reinforcing strategic goals, and improving optimizing

the efficiency and flexibility of the enterprise’s daily

operations (Xu, Xu, et Li 2018; Gancarczyk et

Ujwary-Gil 2020; Saraeian, Shirazi, et Motameni

The Future of BPM in the Era of Industry 4.0: Exploring New Opportunities for Innovation

919

2018; Castro et Teixeira 2021; Kernytska 2024). In

the context of Industry 4.0 and smart manufacturing

systems, BPM plays a crucial role in ensuring that

processes are efficient, agile, and capable of adapting

to new technologies and market demands (Kamble, S.

S., Gunasekaran, A., Ghadge, A., & Raut, R. 2020).

The implementation of BPM significantly impacts

Industry 4.0. Companies adopting advanced BPM

strategy report benefits, such as increased production

efficiency, improved performance monitoring, cost

savings, and a higher rate of automation in production

(Gažová, Papulová, et Smolka 2022).

Furthermore, BPM can drive process innovation

and digital transformation in organizations (Mendling

et al. 2020) by enhancing innovation, agility, and

sustainability through the integration of technologies

like AI, IoT, and Blockchain (Kernytska 2024).

Moreover, BPM enables organizations to adapt to

changing environments, enhancing their ability to

leverage emerging technologies and respond swiftly

to market fluctuations (Ortt, Stolwijk, et Punter

2020). BPM plays a crucial role in enabling

organizations to comply with industry standards,

mitigate risks, and enhance intellectual capital in the

digital era (Broccardo et al. 2024). By automating and

streamlining business processes, BPM significantly

improves operational efficiency and effectiveness

(Nosalska et al. 2019). Furthermore, it enhances

customer experience by enabling organizations to

deliver more personalized and responsive services

(Chauhan et Singh 2019).

In conclusion, BPM is a key tool to support the

digital transformation of organizations, enabling

them to become more competitive, innovative and

agile (Kernytska 2024).

5.2.2 BPM Challenges and Limitations in

the Era of Industry 4.0

While BPM has long been recognized as a key driver

of organizational efficiency, the digital age presents

new challenges (Imgrund and Janiesch 2019). These

challenges include the complexity of integrating

multiple systems and technologies, concerns about

data security and privacy, and the need to upskill the

workers. Resistance to up-skilling the workforce and

organizational changes can hinder BPM

implementation in Industry 4.0 (Szelągowski and

Berniak-Woźny 2022). Additionally, organizations

must enhance flexibility and adaptability to respond

to rapidly changing market conditions and

technological advancements (Chauhan and Singh

2019). Integrating BPM with emerging technologies

like AI, blockchain, and IoT make process

management more complex and subject to

uncertainty, posing significant challenges for

decision-making (Souifi et al. 2022). Current BPMSs

often manage only certain processes leading to

diverging expectations and outcomes (Saraeian,

Shirazi, and Motameni 2018; Pourmirza et al. 2017).

Moreover, the complexities of CPS, which integrate

computational and physical capabilities, require

effective uncertainty management to ensure

reliability (Souifi et al. 2022). The growth of data and

technology has led to significant changes in business

operations. Finally, the challenge of digital

innovation, particularly in creating value from data,

requires a transformation in BPM (Van Looy, 2021).

Security and openness, along with cost and flexibility,

represent a significant challenge in BPM, particularly

in BPM system components that include IoT devices.

BPM systems must seamlessly interact with these

technologies and to be able to leverage their

capabilities and improve business processes

(Elghaish et al. 2021).

BPM discipline has been subjected to significant

challenges in recent years, particularly in the context

of dynamic and complex business environments of

industry 4.0 (Grisold et al. 2021). Companies must

offer higher quality, customized products at

competitive prices and greater flexibility to improve

connectivity in their business processes (Fatorachian

and Kazemi, 2018). To achieve this, organizations

need properly coordinate their local and external

business units, thereby improving BPM flexibility

and optimazing the value chain of inter-

organizational business processes (Bazan and

Estevez 2022). The effectiveness of BPM systems in

Industry 4.0 can be compromised by data quality

issues. Ensuring high-quality data is essential for

accurate decision-making and optimal performance

within these systems (Yokogawa, 2020). The

verification of transactions, for instance, has emerged

as a significant challenge within the domain of

business processes (Viriyasitavat et al. 2019). In their

study, Kerpedzhiev et al. in (Kerpedzhiev et al. 2021)

introduced a new interpretation of the success factors

related to BPM from a digital Innovation perspective.

This perspective emphasizes the dynamic interplay

between technological advancements and

organizational processes, highlighting how digital

tools and methodologies can enhance BPM

effectiveness. However, additional research is

required to develop process innovation theories,

models, and applications that are context-specific and

applicable to various business environments (Van

Looy, 2021).

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

920

5.2.3 BPM Future Directions

The challenges identified in BPM also present

significant opportunities for experts in business

informatics to develop innovative solutions and

frameworks. (Kerpedzhiev et al. 2021) outline key

challenges that BPM must address over the next

decade, emphasizing the importance of strategic

alignment between BPM and business objectives to

achieve meaningful results. A critical direction for

BPM is the integration of AI and machine learning,

which can facilitate more intelligent and autonomous

business processes (Chauhan & Singh, 2019).

Additionally, blockchain technology can enhance

transparency, security, and trust in business processes

(Ortt, Stolwijk, & Punter, 2020), while IoT will enable

real-time monitoring and optimization, improving

visibility and information sharing across supply chains

(Paksoy, Koçhan, & Ali, 2021). These technologies

can provide greater flexibility in production and

product design, reducing development time and

enabling the production of high-quality, customized

products (Chauhan & Singh, 2019; Fatorachian &

Kazemi, 2018). Exploring the intersection of IoT data

and BPM can lead to adaptive processes that respond

in real-time to changing conditions. Furthermore,

frameworks that integrate IoT technologies into

existing BPM systems are essential for maximizing

the benefits of digital transformation while ensuring

robust risk management (Cardoso et al., 2024). The

scalability and adaptability of BPM systems are

crucial for meeting the evolving demands of Industry

4.0 (Rosemann & vom Brocke, 2015). Current BPM

systems manage only certain processes, creating

opportunities for further research. Addressing

challenges related to security, cost, and flexibility

through blockchain technology (BCT) can facilitate

peer-to-peer transactions, reducing reliance on central

authorities (Garcia-Garcia et al., 2020). In this context,

BCT has to be integrated with BPM system

components that usually include IoT devices

(Elghaish F., et al, 2021). BPM should also focus on

balancing innovation and efficiency (Sliż, 2024) by

exploring digital options for process improvements,

complementing its traditional internal focus

(Eikebrokk, Olsen, & Garmann-Johnsen, 2024).

6 BPM: CAPITALIZING ON

INDUSTRY 4.0

OPPORTUNITIES

The emergence of Industry 4.0 has transformed BPM

by enabling process automation, enhancing decision-

making capabilities, and increasing agility in

responding to market demands. A key opportunity

lies in improved process automation through the

integration of technologies such as IoT, AI, and

machine learning, which drive efficiency, cost

reduction, and quality enhancements (Nozari et al.,

2024; Bartlett et al., 2023). Digitalization of business

processes opens new avenues for innovative business

models and organizational structures (Broccardo et

al., 2024). The integration of information and

communication technology (ICT) with BPM not only

streamlines operations but also allows organizations

to swiftly adapt to changing market conditions

(Moreira et al., 2024). Furthermore, the convergence

of BPM with emerging technologies enhances

organizational efficiency and drives transformation

across various industries by facilitating information

transparency, data analysis, and rapid decision-

making (Elghaish et al., 2021). Industry 4.0 also

emphasizes customer-centric processes, aligning

business operations with customer needs to deliver

personalized and efficient experiences (Ahmed &

Shahzad, 2022). The advancement of IoT technology

enables organizations to implement IoT-aware

business processes, enhancing their ability to sense

and respond proactively to environmental changes

(Cardoso et al., 2024). Overall, Industry 4.0 offers

substantial cost savings in manufacturing through

improved process control, real-time monitoring, and

enhanced decision-making (Ghobakhloo, 2020;

Fatorachian & Kazemi, 2018).

7 SYNTHESIS AND

CONCLUSIONS

This systematic literature review has made several

significant contributions to the research domain at the

intersection of BPM and Industry 4.0:

A Comprehensive Overview: The SLR

provides a thorough examination of the current

state of research on BPM in the context of

Industry 4.0, highlighting key opportunities,

limitations, and future research directions. This

comprehensive overview serves as a

foundational resource for researchers and

practitioners seeking to understand the evolving

landscape of BPM in the digital age.

Identification of Key Challenges and

Opportunities: By synthesizing existing

literature, this review identifies critical

challenges that organizations face when

integrating BPM with Industry 4.0 technologies,

The Future of BPM in the Era of Industry 4.0: Exploring New Opportunities for Innovation

921

such as data security, process standardization,

and the need for agility. Additionally, it

highlights the opportunities presented by

advanced technologies like AI, IoT, and

blockchain, which can enhance process

automation and decision-making.

Framework for Future Research: The

findings of this review outline a framework for

future research that emphasizes the need for

studies focused on the integration of BPM with

emerging technologies. This framework

encourages researchers to explore innovative

practices that balance traditional BPM principles

with the demands of Industry 4.0, thereby

advancing theoretical and practical knowledge in

the field.

Insights into Risk Management: The

review underscores the role of BPM in

establishing robust risk management processes in

the face of increased cybersecurity threats and

data privacy concerns. This insight contributes to

the literature by emphasizing the importance of

integrating risk management into BPM

frameworks, particularly in the context of digital

transformation.

Focus on Customer-Centric Processes:

The synthesis highlights the shift towards

customer-centric processes facilitated by

Industry 4.0 technologies. This contribution

encourages further exploration of how BPM can

be adapted to enhance customer experiences and

align business processes with customer needs in

a rapidly changing environment.

Call for Interdisciplinary Research: By

addressing the convergence of BPM with various

advanced technologies, this review advocates for

interdisciplinary research that combines insights

from fields such as information systems,

operations management, and data analytics. This

call for collaboration can lead to more holistic

approaches to understanding and leveraging

BPM in the context of Industry 4.0.

In conclusion, the integration of BPM with

Industry 4.0 provides a foundation for organizations

to enhance their processes, drive innovation, and

improve overall performance. By leveraging the

strengths of both BPM and Industry 4.0 technologies,

organizations can position themselves for success in

the digital economy, ensuring they remain

competitive and responsive to the demands of the

future.

REFERENCES

Aalst, Wil M. P. van der, Arthur H. M. ter Hofstede, and

Mathias Weske. 2003. “Business Process Management:

A Survey.” In Lecture Notes in Computer Science

(Including Subseries Lecture Notes in Artificial

Intelligence and Lecture Notes in Bioinformatics),

2678:1–12. Springer, Berlin, Heidelberg.

Adolph, Lars, Thomas Anlahr, Heinz Bedenbender,

Alexander Bentkus, Lennart Brumby, and Christian

Diedrich. 2016. “German Standardization Roadmap:

Industry 4.0.” Version 2. Berlin: DIN EV.

Ahmed S. and Shahzad K., "Augmenting Business Process

Model Elements with End-User Feedback," in IEEE

Access, vol. 10, pp. 115635-115651, 2022,

Alghamdi, Hassan. 2024. “Assessing the Impact of

Enterprise Architecture on Digital Transformation

Success: A Global Perspective.” Sustainability 16 (20):

8865.

Arnold, Christian, Daniel Kiel, and Kai-Ingo Voigt. 2016.

“How Industry 4.0 Changes Business Models in

Different Manufacturing Industries.” International

Journal of Innovation Management 20 (08): 1640015.

Baduge, S. K., Thilakarathna, S., Perera, J. S., Arashpour,

M., Sharafi, P., Teodosio, B., ... &Mendis, P. (2022).

Artificial intelligence and smart vision for building and

construction 4.0: Machine and deep learning methods

and applications. Automation in Construction, 141,

104440.

Bai, C., Dallasega, P., Orzes, G., & Sarkis, J. (2020).

Industry 4.0 technologies assessment: A sustainability

perspective. International journal of production

economics, 229, 107776.

Baiyere, Abayomi, HannuSalmela, and TommiTapanainen.

2020. “Digital Transformation and the New Logics of

Business Process Management” European Journal of

Information Systems 29 (3): 238–59.

Bartlett, L., Kabir, M. A., & Han, J. (2023). A review on

business process management system design: the role

of virtualization and work design. IEEE Access.

Bazan, Patricia, and Elsa Estevez. 2022. “Industry 4.0 and

Business Process Management: State of the Art and

New Challenges.” Business Process Management

Journal 28 (1): 62–80

Berlak, Joachim, Stefan Hafner, and Volker G.

Kuppelwieser. 2021. “Digitalization’s Impacts on

Productivity: A Model-Based Approach and Evaluation

in Germany’s Building Construction Industry.”

Production Planning & Control 32 (4): 335–45.

Bouwman, Harry, Shahrokh Nikou, Francisco J. Molina-

Castillo, and Mark de Reuver. 2018. “The Impact of

Digitalization on Business Models.” Digital Policy,

Regulation and Governance 20 (2): 105–24.

Broccardo, Laura, Paola Vola, Safiya Mukhtar Alshibani,

and Riccardo Tiscini. 2024. “Business Processes

Management as a Tool to Enhance Intellectual Capital

in the Digitalization Era: The New Challenges to Face.”

Journal of Intellectual Capital 25 (1): 60–91.

Butt, Javaid. 2020. “A Conceptual Framework to Support

Digital Transformation in Manufacturing Using an

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

922

Integrated Business Process Management Approach.”

Designs 4 (3): 17.

Cardoso P. B., Respício A. and Domingos D., "A Granular

Risk Analysis Approach for IoT-Aware Business

Processes," in IEEE Access, vol. 12, pp. 142058-

142070, 2024.

Castro, S, and L Teixeira. 2021. “Industry 4.0 and Business

Process Management: An Exploratory Study on the

Bilateral Effects.” In Proceedings of the International

Conference on Industrial Engineering and Operations

Management, 4840–47.

Chauhan, Chetna, and Amol Singh. 2019. “A Review of

Industry 4.0 in Supply Chain Management Studies.”

Journal of Manufacturing Technology Management 31

(5): 863–86.

Chrusciak, Camilla Buttura, Anderson Luis Szejka, and

Osiris Canciglieri Junior. 2023. “An Exploratory

Literature Study into Digital Transformation to Support

Business Management Processes.” In International

Conference on Production Research, 513–21. Springer.

Di Ciccio, C., Marrella, A., & Russo, A. 2015.

“Knowledge-Intensive Processes: Characteristics,

Requirements and Analysis of Contemporary

Approaches”. Journal on Data Semantics, 4 (1): 29–57.

Colombo, Armando W., Dirk Schleuter, and Matthias

Kircher. 2015. “An Approach to Qualify Human

Resources Supporting the Migration of SMEs into an

Industrie4.0-Compliant Company Infrastructure.” In

IECON 2015 - 41st Annual Conference of the IEEE

Industrial Electronics Society, 003761–66. IEEE.

Corallo, Angelo, Mariangela Lazoi, and Marianna Lezzi.

2020. “Cybersecurity in the Context of Industry 4.0: A

Structured Classification of Critical Assets and

Business Impacts.” Computers in Industry 114

(January): 103165.

Czvetkó, Tímea, Alex Kummer, TamásRuppert, and

JánosAbonyi. 2022. “Data-Driven Business Process

Management-Based Development of Industry 4.0

Solutions.” CIRP Journal of Manufacturing Science

and Technology 36 (January): 117–32.

Dumitriu, Dan. 2018. “Research on the Trend and Potential

Impact of Adopting BPM Techniques over General

Performance of the Organization.” Procedia

Manufacturing 22: 575–82.

Eikebrokk, Tom R., Dag H. Olsen, and Niels F. Garmann-

Johnsen. 2024. “Conceptualizing Business Process

Management Capabilities in Digitalization Contexts.”

Procedia Computer Science 239 (2023): 330–37.

Elghaish, F., Hosseini, M. R., Matarneh, S., Talebi, S., Wu,

S., Martek, I., ... &Ghodrati, N. (2021). Blockchain and

the ‘Internet of Things' for the construction industry:

research trends and opportunities. Automation in

construction, 132, 103942.

Fatorachian, Hajar, and HadiKazemi. 2018. “A Critical

Investigation of Industry 4.0 in Manufacturing:

Theoretical Operationalisation Framework.”

Production Planning & Control 29 (8): 633–44.

Flechsig, Christian, Jacob Lohmer, Robert Voß, and Rainer

Lasch. 2022. “Business Process Maturity Model for

Digital Transformation: An Action Design Research

Study on The Integration of Information Technology.”

International Journal of Innovation Management 26

(03).

Gajšek, Brigita, and NatašaVujica Herzog. 2020. “Smart

Glasses in Sustainable Manual Order Picking Systems.”

Sustainable Logistics and Production in Industry 4.0:

New Opportunities and Challenges, 219–41.

Gancarczyk, Marta, and Anna Ujwary-Gil. 2020.

“Improving Business Processes and Process

Organization from the Industry 4.0 Perspective.” In

New Challenges in Economic Policy, Business, and

Management, 11–29.

Garcia-Garcia, Julian Alberto, et al. "Using blockchain to

improve collaborative business process management:

Systematic literature review." IEEE Access 8 (2020):

142312-142336.

Gartner. 2016. “BPM Is Critical to Business

Transformation Success.” Gartner. 2016.

https://www.gartner.com/smarterwithgartner/bpm-is-

critical-to-business-transformation-success.

Gartner. 2018. “Gartner Says BPM Is Critical for Business

Transformation Success.” 2018.

Gažová, Andrea, Zuzana Papulová, and DávidSmolka.

2022. “Effect of Business Process Management on

Level of Automation and Technologies Connected to

Industry 4.0.” Procedia Computer Science 200 (2019):

1498–1507.

Ghobakhloo, Morteza. 2020. “Industry 4.0, Digitization,

and Opportunities for Sustainability.” Journal of

Cleaner Production 252 (4): 119869.

Grisold, Thomas, Jan vomBrocke, Steven Gross, Jan

Mendling, Maximilian Röglinger, and Katharina Stelzl.

2021. “Digital Innovation and Business Process

Management: Opportunities and Challenges as

Perceived by Practitioners.” Communications of the

Association for Information Systems 49 (1): 556–71.

Guo, Junlang, JiewuLeng, J. Leon Zhao, Xueliang Zhou,

Yu Yuan, Yuqian Lu, Dimitris Mourtzis, et al. 2024.

“Industrial Metaverse towards Industry 5.0:

Connotation, Architecture, Enablers, and Challenges.”

Journal of Manufacturing Systems 76 (January): 25–42.

Horalek, Josef, Tereza Otcenaskova, Vladimir Sobeslav,

and Petr Tucnik. 2024. “A Business Process and Data

Modelling Approach to Enhance Cyber Security in

Smart Cities.” In Mobile Networks and Applications,

21:70–84.

Imgrund, Florian, and Christian Janiesch. 2019.

“Understanding the Need for New Perspectives on

BPM in the Digital Age: An Empirical Analysis.” In

Lecture Notes in Business Information Processing, 362

LNBIP:288–300.

Kamble, S. S., Gunasekaran, A., Ghadge, A., & Raut, R.

(2020). A performance measurement system for

industry 4.0 enabled smart manufacturing system in

SMMEs-A review and empirical investigation.

International journal of production economics, 229,

107853.

Kernytska, Anna. 2024. “Beyond Optimization: The

Evolving Role of Business Process Management in

Industry Transformation.” 103 (4).

The Future of BPM in the Era of Industry 4.0: Exploring New Opportunities for Innovation

923

Kerpedzhiev, Georgi, Ulrich Matthias König, Maximilian

Röglinger, and Michael Rosemann. 2021. “An

Exploration into Future Business Process Management

Capabilities in View of Digitalization.” Business &

Information Systems Engineering 63 (2): 83–96.

Lee, Ching Hung, Chien Liang Liu, Amy J.C. Trappey,

John P.T. Mo, and Kevin C. Desouza. 2021.

“Understanding Digital Transformation in Advanced

Manufacturing and Engineering: A Bibliometric

Analysis, Topic Modeling and Research Trend

Discovery.” Advanced Engineering Informatics 50

(October): 101428.

Liu, Day‐Yang, Shou‐Wei Chen, and Tzu‐Chuan Chou.

2011. “Resource Fit in Digital Transformation”

Management Decision 49 (10): 1728–42.

Looy, Amy Van. 2021. “A Quantitative and Qualitative

Study of the Link between Business Process

Management and Digital Innovation” Information &

Management 58 (2): 103413.

Mendling, Jan, Brian T Pentland, Jan Recker, Jan

Mendling, and Brian T Pentland. 2020. “Building a

Complementary Agenda for Business Process

Management and Digital Innovation Digital

Innovation.” European Journal of Information Systems

29 (3): 208–19.

Moher, David, Alessandro Liberati, Jennifer Tetzlaff, and

Douglas G. Altman. 2010. “Preferred Reporting Items

for Systematic Reviews and Meta-Analyses: The

PRISMA Statement.” International Journal of Surgery

8 (5): 336–41.

Nosalska, Katarzyna, Zbigniew MichałPiątek, Grzegorz

Mazurek, and Robert Rządca. 2019. “Industry 4.0:

Coherent Definition Framework with Technological

and Organizational Interdependencies.” Journal of

Manufacturing Technology Management 31 (5): 837–

62.

Nozari, H., Ghahremani-Nahr, J., &Szmelter-Jarosz, A.

(2024). AI and machine learning for real-world

problems. In Advances in Computers (Vol. 134, pp. 1-

12). Elsevier.

Ortt, Roland, Claire Stolwijk, and Matthijs Punter. 2020.

“Implementing Industry 4.0: Assessing the Current

State.” Journal of Manufacturing Technology

Management 31 (5): 825–36.

Paksoy, Turan, ÇiğdemKoçhan, and Sadia Samar Ali. 2021.

Logistics 4.0: Digital Transformation of Supply Chain

Management. CRC Press.

Pourmirza, Shaya, Sander Peters, Remco Dijkman, and

Paul Grefen. 2017. “A Systematic Literature Review on

the Architecture of Business Process Management

Systems.” Information Systems 66: 43–58.

Moreira, H. S. Mamede and A. Santos, "Business Process

Automation in SMEs: A Systematic Literature

Review," in IEEE Access, vol. 12, pp. 75832-75864,

2024,

Saraeian, Shideh, Babak Shirazi, and HomayunMotameni.

2018. “Towards an Extended BPMS Prototype: Open

Challenges of BPM to Flexible and Robust Orchestrate

of Uncertain Processes.” Computer Standards &

Interfaces 57: 1–19.

Sliż, Piotr. 2024. “Ambidextrous Business Process

Management: Unleashing the Dual Power of

Innovation and Efficiency BT.” In, edited by Jochen De

Weerdt and LuisePufahl, 552–64. Cham: Springer

Nature Switzerland.

Souifi, Amel, Zohra Cherfi Boulanger, Marc Zolghadri,

Maher Barkallah, and Mohamed Haddar. 2022.

“Uncertainty of Key Performance Indicators for

Industry 4.0: A Methodology Based on the Theory of

Belief Functions.” Computers in Industry 140: 103666.

Stefanescu, D., Montalvillo, L., Urbieta, A., Galán-García,

P., &UnzillaGalan, J. J. (2024). Smart Contract

Powered Framework for the Next Generation Industry

4.0 Business Model. Distributed Ledger Technologies:

Research and Practice, 3(4), 1-24.

Su, Dan, Lijun Zhang, Hua Peng, ParvanehSaeidi, and

ErfanBabaeeTirkolaee. 2023. “Technical Challenges of

Blockchain Technology for Sustainable Manufacturing

Paradigm in Industry 4.0 Era Using a Fuzzy Decision

Support System.” Technological Forecasting and

Social Change 188 (January): 122275.

Sierakowski. 2024. “BPM Challenges, Limitations and

Future Development Directions – a Systematic

Literature Review.” Business Process Management

Journal 30 (2): 505–57.

Tupa, Jiri, and Frantisek Steiner. 2019. “Industry 4.0 and

Business Process Management.” TehničkiGlasnik 13

(4): 349–55.

Vaska, Selma, Maurizio Massaro, Ernesto Marco

Bagarotto, and Francesca Dal Mas. 2021. “The Digital

Transformation of Business Model Innovation: A

Structured Literature Review.” Frontiers in Psychology

11 (January): 539363.

Viriyasitavat, Wattana, Li Da Xu, Zhuming Bi, and Vitara

Pungpapong. 2019. “Blockchain and Internet of Things

for Modern Business Process in Digital Economy—the

State of the Art.” IEEE Transactions on Computational

Social Systems 6 (6): 1420–32.

Weske, Mathias. 2019. “Business Process Management

Architectures.” In Business Process Management, 351–

84. Berlin, Heidelberg: Springer Berlin Heidelberg.

Xu, Li Da, Eric L. Xu, and Ling Li. 2018. “Industry 4.0:

State of the Art and Future Trends.” International

Journal of Production Research 56 (8): 2941–62.

Yang, Q., Liu, Y., Chen, T., & Tong, Y. (2019). Federated

machine learning: Concept and applications. ACM

Transactions on Intelligent Systems and Technology

(TIST), 10(2), 1-19.

Zhang, C., & Chen, Y. (2020). A review of research

relevant to the emerging industry trends: Industry 4.0,

IoT, blockchain, and business analytics. Journal of

Industrial Integration and Management, 5(01), 165-

180.

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

924