A Predictive Greenhouse Digital Twin for Controlled Environment

Agriculture

Abdellah Islam Kafi

a

, Antonio P. Sanfilippo

b

, Raka Jovanovic

c

and Sa’d Abdel-Halim Shannak

d

Qatar Environment and Energy Research Institute, Hamad Bin Khalifa University, Doah, Qatar

fi fi

Keywords:

Digital Twin, Controlled Environment Agriculture, Time Series Forecasting, Machine Learning, Crop Yield

Modeling, Edge Implementation.

Abstract:

Controlled environment agriculture offers significant advantages for the efficient use of resources in food

production, especially in hot desert climate regions due to the scarcity of arable land and water. However,

farming practices such as hydroponics and aquaponics have high energy requirements for temperature con-

trol and present higher operational complexity when compared to traditional forms of farming. This study

describes a Predictive Greenhouse Digital Twin (PGDT) that addresses these challenges through a dynamic

crop yield assessment. The PGDT uses greenhouse measurements gathered through an IoT sensor network

and a regression approach to multivariate time series forecasting to develop a model capable of predicting final

crop yield as a function of the gathered measurements at any point in the crop cycle. The performance of the

PGDT is evaluated with reference to forecasting algorithms based on deep and ensemble learning methods.

Overall, deep learning methods show superior performance, with Long short-term memory (LSTM) providing

a marginal advantage compared to Deep Neural networks (DNN). Furthermore, the models were deployed on

an edge device (a Raspberry Pi-based gateway), where DNN demonstrated faster inference while delivering

performance better than LSTM.

1 INTRODUCTION

As climate change keeps driving desertification

through land degradation (Sivakumar, 2007) (Huang

et al., 2020), food crop production becomes increas-

ingly challenging, especially in hot desert climate re-

gions due to the scarcity of water and arable land.

For example, only 2.6% of Qatar’s land was allo-

cated to food production in 2019 (Planning and Au-

thority, 2021) and only a small portion of the al-

ready scarce ground water is suitable for crop irriga-

tion due to the presence of total dissolved solids con-

centration levels which are not suitable for food crops

(Sanfilippo et al., 2024). Hydroponic and aquaponic

farming alleviate these impediments through soil-less

farming and significant reduction of water use but

have high energy requirements for temperature con-

trol and present higher operational complexity when

a

https://orcid.org/0000-0001-8523-3492

b

https://orcid.org/0000-0001-7097-4562

c

https://orcid.org/0000-0001-8167-1516

d

https://orcid.org/0000-0002-6842-7479

compared to traditional forms of farming (Sanfilippo

et al., 2024). Both problems can be addressed through

the development of a Predictive Greenhouse Digital

Twin (PGDT) that can help identify the most efficient,

profitable and sustainable use of resources in achiev-

ing the highest crop yields.

The PGDT presented in this study provides the

basis for the automatic identification of economically

sustainability in indoor farming through dynamic as-

sessment of crop yield at any stage during the produc-

tion cycle. The PGDT uses greenhouse measurements

from a IoT sensor network and a regression approach

to multivariate time series forecasting to provide a

model capable to predict crop productivity as a func-

tion of the collected measurements. The integration of

the PGDT with multi-objective optimization and tech-

noeconomic analysis components can then be used to

identify ideal trade-offs in the use of resources such as

electricity, water and nutrients, and evaluate the eco-

nomic sustainability of the ensuing trade-off scenar-

ios as discussed in (Sanfilippo et al., 2024). The per-

formance of the PGDT is evaluated with reference to

three forecasting algorithms, two based on deep learn-

980

Kafi, A. I., Sanfilippo, A. P., Jovanovic, R. and Shannak, S. A.-H.

A Predictive Greenhouse Digital Twin for Controlled Environment Agriculture.

DOI: 10.5220/0013479900003929

In Proceedings of the 27th International Conference on Enterprise Information Systems (ICEIS 2025) - Volume 1, pages 980-987

ISBN: 978-989-758-749-8; ISSN: 2184-4992

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

ing methods (Deep Neural networks (DNN) and Long

short-term memory (LSTM)) and the third based on

the eXtreme Gradient Boosting algorithm (XGBoost).

The paper is structured into five sections. First,

a review of the background literature on crop yield

modeling is provided to highlight the contribution of

the present study. Then the data used in this study

and their sources are discussed. Next, the methodol-

ogy used in the development of the PGDT is described

and finally the results are presented. The paper con-

cludes with a discussion of next steps with specific

reference to integration with the multi-objective opti-

mization and techno-economic analysis components.

2 BACKGROUND

Work on PGDTs as predictive models of greenhouse

productivity can be grouped into two main categories

according to whether first principle models or ma-

chine learning algorithms are used.

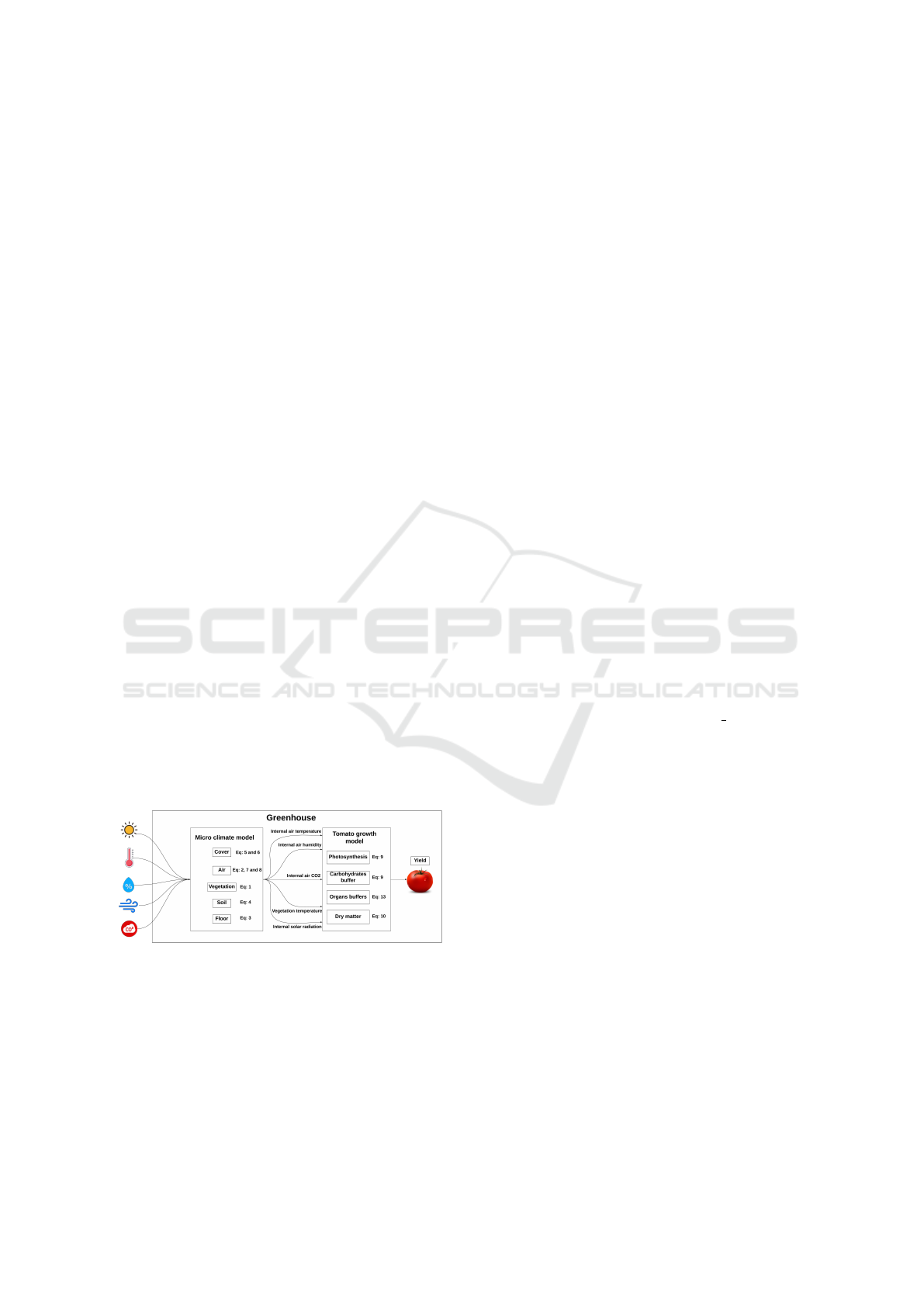

An example of PGDT based on first principle

models is presented in (Sanfilippo et al., 2024) us-

ing the greenhouse micro-climate and tomato yield

models developed in (Vanthoor et al., 2011b) and

(Vanthoor et al., 2011a). The greenhouse micro-

climate includes equations that compute the impact

of factors relative to climate control in the green-

house such as the insulation properties of the plastic

sheeting covering the greenhouse, ventilation, the ab-

sorption of near-infrared radiation, plant transpiration

rate, and fluxes generated by the plants’ canopy activ-

ity. The tomato growth model employs a shared car-

bohydrate buffer that handles the distribution to plant

organs and is primarily influenced the micro-climate

model, as shown in Figure 1.

Figure 1: Example of PGDT based on a first principles

model (Sanfilippo et al., 2024).

Most PGDTs based on machine learning make use

of neural network algorithms. One of the earliest

studies (Ehret et al., 2011) provides a neural network

model of greenhouse tomato yield, growth and water

use from automated crop monitoring data. The study

described in (Qaddoum et al., 2013) used fuzzy neural

networks to model tomato yield. The authors in (Alh-

naity et al., 2019) make use of a long short-term mem-

ory neural network algorithm to model plant growth

in greenhouses and show that the model developed

outperforms support vector regression and random

forest algorithms. The authors in (Gong et al., 2021)

present a greenhouse crop yield prediction model that

combines temporal convolutional and recurrent neu-

ral networks and rivals traditional machine learning

approaches such as linear regression, random for-

est, support vector regression, decision tree, gradient

boosting, and multi-layers artificial neural network.

These studies all represent significant advanced in

modeling crop growth in a greenhouse environment.

Our study contributes to this endeavor through the

comparison of deep learning algorithms with the eX-

treme Gradient Boosting algorithm (XGBoost).

3 DATA

The data used in this study include meteorolog-

ical measurements outside the greenhouse moni-

tored through the National Solar Radiation Database

(NSRD) (https://nsrdb.nrel.gov) and measurements

from a hydroponic tomato greenhouse at the Agrico

Agricultural Development (https://agrico.qa). Green-

house measurements were gathered through a net-

work of IoT sensors installed in the hydroponic

tomato greenhouse throughout a full tomato growth

cycle, early November 2023 through the end of May

2024. These include electrical soil conductivity (EC),

luminosity (LUX), soil temperature (S TEMP), rela-

tive humidity (RH), air temperature (TEMP), pH, and

harvest quantities, as shown in Tables I and II. Har-

vest quantities were manually recorded and provide

the key indication of crop yield. For additional details

on the greenhouse characteristics and the IoT sensor

network see (Sanfilippo et al., 2024).

4 METHODOLOGY

The primary objective of this study is to assess and

compare the performance of three distinct forecasting

algorithms, DNN, LSTM, and XGBoost, in predicting

crop yield. A methodical approach was employed for

data collection, preprocessing, model development,

training procedures, and performance evaluation. The

most adequate models were chosen for implementa-

tion on an edge device to enable immediate yield fore-

casting in the greenhouse environment. The approach

included transforming the trained models into com-

pact formats appropriate for edge deployment and uti-

lizing quantization methods to minimize the models’

A Predictive Greenhouse Digital Twin for Controlled Environment Agriculture

981

memory usage and inference delay. The implementa-

tion setup was integrated with the existing IoT sensor

network, allowing seamless data flow.

4.1 DNN, LSTM and XGBoost

The architecture of DNNs (Sze et al., 2017) comprises

input, hidden and output layers. The input layer re-

ceives data. The hidden layers consist of intercon-

nected nodes where data inputs are associated with

weights. Each node computes the weighted sum of

its inputs and passes the results through an activation

function. Activated nodes are summed and passed

through to the output layer as predictions. During

training, forward and backward propagation steps op-

erate on training data records. In forward propaga-

tion, data are fed into the input layer, passed through

each hidden layer, and the network’s prediction is

generated from the final output layer. In backward

propagation, the network’s prediction is compared to

the observed value, the ensuing error is propagated

backward through the network layer by layer, and

the weights of the connections between nodes are ad-

justed using algorithms such as gradient descent to

minimize the error.

Differently from DNNs, an LSTM (Hochreiter,

1997) is structured as a network of cells. Each cell

contains a memory component, a forget gate, an input

gate and an output gate. After the LSTM cell receives

input data, the forget gate determines which informa-

tion from the previous step is to be discarded and the

input gate determines which new information should

be stored in memory. A new candidate value is com-

puted using the previous hidden state of the network,

the current input, and the input gate. The memory cell

is updated by combining the old memory cell content

with the new candidate value, weighted by the forget

gate and input gate values, respectively. The output

gate decides how much of the updated memory cell

content should be used to compute the output of the

cell. The final output of the LSTM cell is computed

by multiplying the output gate value with the updated

memory cell content.

In XGBoost (Chen and Guestrin, 2016) weak

learners are iteratively combined to minimize the en-

semble error. The model is initialized with a weak

learner, e.g., a decision stump model (Iba and Lang-

ley, 1992), which is evaluated on the reference dataset

to compute residuals using a loss function such as

the Mean Squared Error (MSE). Then, a new weak

learner is built that minimizes the loss function by

fitting the new weak learner to the dataset with the

objective of predicting both the first and second or-

der gradients of the loss function from the previous

Table 1: Harvest quantities time series sample.

Date Harvest Quantities (Kg.)

01/03/24 21

01/06/24 80

01/06/24 27

01/06/24 6

01/08/24 200

01/08/24 22

01/08/24 1

... ...

Table 2: Parameters measured in near real-time and aggre-

gated daily.

Date EC LUX S TEMP RH TEMP pH

06/11/23 0.7 8971.3 27.4 61.6 26.1 4.3

07/11/23 0.9 11891.4 26.7 61.1 26.4 4.9

... ... ... ... ... ... ...

weak learner. Finally, the ensemble model is updated

by adding a scaled version of the weak learner’s pre-

diction. This process is repeated until the optimal re-

sults are achieved and the final model is derived as the

weighted mean of all weak learners.

4.2 Data Wrangling

Before training and evaluating the DNN, LSTM and

XGBoost forecasting algorithms on the reference

dataset, the relation in time and frequency granular-

ity between the dependent variable, i.e., harvest quan-

tities, and the independent variables, i.e., EC, LUX,

S TEMP, RH, TEMP, and pH, in the dataset need to

be normalized. Harvest quantities are typically dis-

tributed unevenly through the production cycle, with

no output in the initial period of growth (i.e, early

November through early January in Qatar), multiple

or single collections of varying quantities in a sin-

gle day, and intervening days with no collection, as

shown in Table (1), while other parameters are mea-

sured in near real-time and aggregated daily as shown

in Table (2). So, while there are data points for every

day of the crop growth cycle (209 days) for the inde-

pendent variables, there are only 101 data points for

the dependent variable (i.e., harvest quantities) that

represent a total of 37 days taking into account days

of repeated harvesting.

We employed a sliding window technique to cap-

ture the temporal dependencies inherent in green-

house sensor data during feature engineering. This

method involves creating subsets of consecutive data

points, where each subset (or window) contains a

fixed number of time steps—in this case, eight days.

For every window, the corresponding input features

are aggregated to form a feature vector representing

the greenhouse’s state over the preceding eight-day

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

982

period. Specifically, each window includes measure-

ments of EC, LUX, HUM, TEMP, YIELD, and the

number of days since the start of the plantation cycle.

The target variable for each window is the yield value

following the window period. By sliding this window

across the entire dataset, we generated many training

samples that enabled the models to learn patterns and

trends associated with crop growth and yield fluctua-

tions.

We employed a forward-filling method to assign

missing yield values to address the non-daily record-

ing of harvest quantities. Specifically, after a har-

vest event was recorded on a particular day, the cor-

responding yield value was carried forward and as-

signed to all subsequent days until the next harvest

day. This technique assures that the yield data stays

constant during periods without recorded harvests re-

flecting the real-world available information. By do-

ing so, the model can leverage the most recent yield

information when predicting future yields while min-

imizing the introduction of bias that could result from

arbitrary interpolation.

4.3 Training and Testing

We explore the architecture design and training pro-

cedures employed for each predictive model inte-

grated into the PGDT. We explore three distinct mod-

eling approaches: DNN, LSTM, and XGBoost. Each

model’s architecture, hyperparameter configurations,

and training methodologies are detailed to provide

a comprehensive understanding of their implementa-

tion characteristics. The training was conducted on

a Linux machine with an AMD Ryzen 7900 12-core

processor, an NVIDIA RTX 4070 GPU with 12 GB

of VRAM, and 32GB of DDR4 RAM. During train-

ing, the DNN and LSTM models were trained on the

GPU. The XGBoost model, implemented using the

XGBoost library, was trained on the CPU.

4.3.1 Deep Neural Network

The DNN model begins with an input layer that ac-

cepts data sequences with eight-time steps window

size. Subsequently, these multidimensional inputs are

flattened into a single vector to facilitate processing

by the dense layers. The DNN comprises two fully

connected hidden layers containing 256 neurons with

ReLU activation functions.

Training the DNN involved using the Adam op-

timizer with a learning rate 0.001, aiming to mini-

mize the Mean Squared Error (MSE) loss function.

The model was trained over 100 epochs with a batch

size of 32. TimeSeriesSplit with eight splits was em-

ployed for cross-validation, maintaining the chrono-

logical integrity of the time series data. Feature scal-

ing was performed using the MinMaxScaler, which

normalized the input features to a range between 0

and 1.

4.3.2 Long Short-Term Memory Network

The LSTM architecture begins with an input layer that

processes sequences of eight-time steps, each com-

prising six features similar to the DNN model. This

input is fed into a stack of LSTM layers, each con-

taining 256 memory units.

Each LSTM layer is equipped with dropout regu-

larization, although the current configuration sets the

dropout rate to 0.2 to control overfitting. The output

is a dense layer with a linear activation function, gen-

erating the predicted yield value.

Training the LSTM model utilized the Adam op-

timizer with a learning rate 0.001 and aimed to min-

imize the MSE loss function. The model was trained

for 100 epochs with a batch size of 32, TimeSeriesS-

plit with eight splits for cross-validation, and feature

scaling was similarly performed using the MinMaxS-

caler to normalize input features.

4.3.3 eXtreme Gradient Boosting

The XGBoost architecture was configured with a

learning rate of 0.1, 200 estimators, and a maximum

tree depth of six. Additionally, a subsample ratio of

0.8 was employed by randomly sampling 80% of the

training data for each tree. These hyperparameters

were selected to balance model complexity and gen-

eralization performance.

Training the XGBoost model involved fitting the

algorithm to the scaled training data using the Min-

MaxScaler to normalize the input features. The model

was trained over 200 boosting rounds with a learning

rate of 0.1, and it was optimized based on the gradient

of the loss function.

4.3.4 Evaluation Procedures

Each model’s performance was evaluated using key

metrics, including ,

Root Mean Squared Error (RMSE),

RMSE =

s

1

n

n

∑

i=1

(y

i

− ˆy

i

)

2

,

coefficient of determination (R

2

),

R

2

= 1 −

∑

n

i=1

(y

i

− ˆy

i

)

2

∑

n

i=1

(y

i

− ¯y)

2

,

and Mean Absolute Error (MAE),

MAE =

1

n

n

∑

i=1

|

y

i

− ˆy

i

|

.

A Predictive Greenhouse Digital Twin for Controlled Environment Agriculture

983

These metrics comprehensively assess each model’s

accuracy and generalization capability.

Furthermore, Mean Squared Error (MSE) is used

for the loss function and given by:

MSE =

1

n

n

∑

i=1

(y

i

− ˆy

i

)

2

,

Where:

• y

i

is the actual value,

• ˆy

i

is the predicted value,

• ¯y is the mean of the actual values,

• n is the number of observations.

5 RESULTS AND DISCUSSION

The experimental evaluation of the PGDT high-

lights different performance aspects among the DNN,

LSTM, and XGBoost models when forecasting green-

house tomato yields using the time series dataset de-

scribed in Section 3. This section presents an in-depth

discussion of the comparative performance of these

methods.

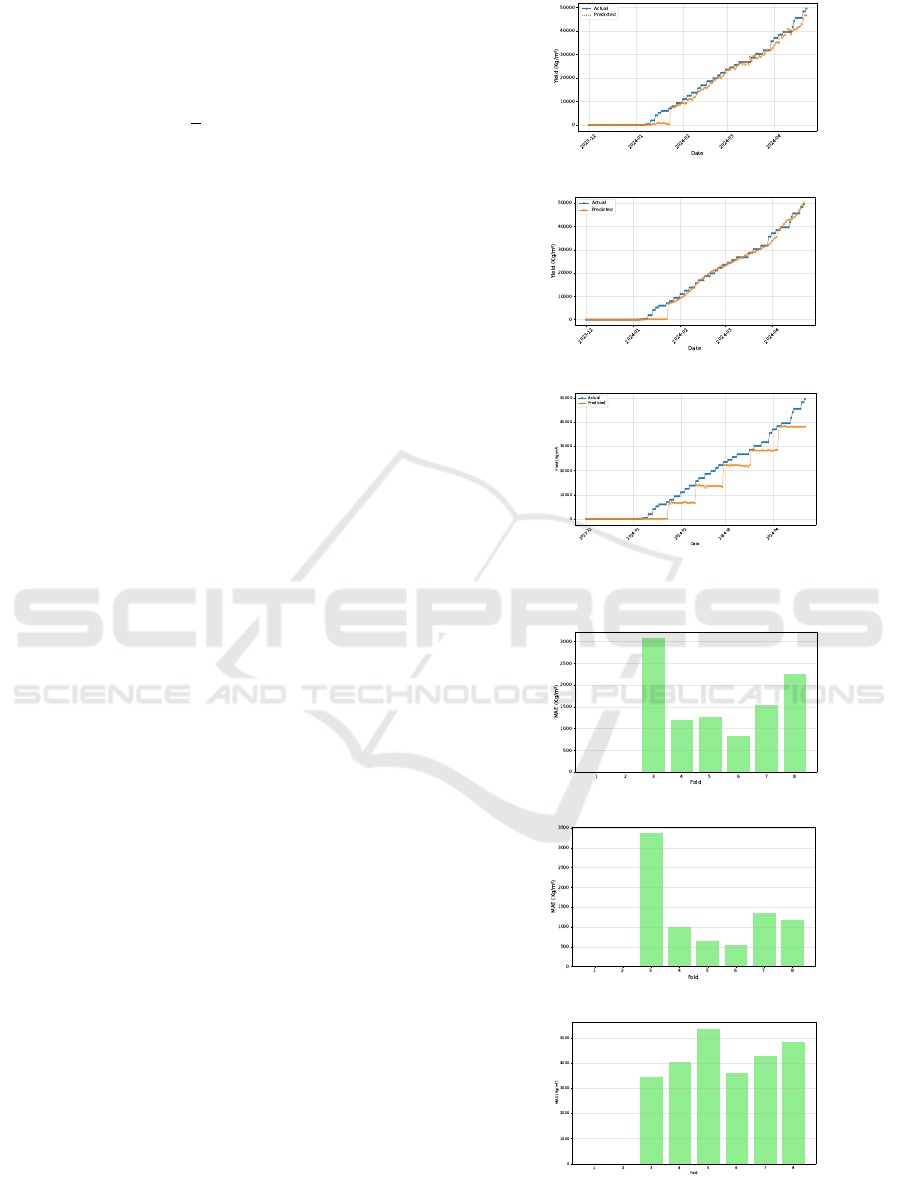

Figure 2 illustrates the actual versus predicted

yields for each model across the whole crop cycle,

catching both the beginning of fruit production and

the peak yield phase. Although all models exhibit a

general upward trend, their fidelity to ground truth

varies substantially, especially near the peak yield

phase.

Generally, Figure 2 demonstrates that DNN and

LSTM capture yield patterns. LSTM predictions

align more robustly with the ground truth observa-

tions. XGBoost, despite its overall ability to follow

the trend, always underestimates yield values. These

initial observations are further quantified in the sub-

sections below.

5.1 Metrics Analysis

Key metrics are employed to evaluate predictive ac-

curacy: MAE, RMSE, and (R

2

).

LSTM achieves the lowest MAE (1,007.39 kg/m

2

)

and RMSE (1,769.86 kg/m

2

), outperforming both

DNN and XGBoost. These lower error values indi-

cate that, on average, LSTM predictions remain closer

to actual harvest quantities and that more significant

prediction errors are less frequent.

Figure 3 shows the evolution of MAE across dif-

ferent folds, demonstrating the model stability with

various data subsets. LSTM consistently achieves

MAE values below 1,500 kg/m

2

across all folds, re-

flecting strong generalization. In contrast, the DNN

(a) DNN.

(b) LSTM.

(c) XGBoost.

Figure 2: Actual vs. predicted yields.

(a) DNN.

(b) LSTM.

(c) XGBoost.

Figure 3: MAE progression across folds.

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

984

exhibits moderate fluctuations, with some folds rising

to nearly 1,800 kg/m

2

, implying sensitivity to partic-

ular training subsets. XGBoost, on the other hand,

displays significant fluctuations, with errors exceed-

ing 4,000 kg/m

2

in the later folds.

(a) DNN.

(b) LSTM.

(c) XGBoost.

Figure 4: RMSE trends across folds.

The RMSE results, plotted in Figure 4, follow the

MAE trends. DNN registers moderate RMSE fluc-

tuations, while LSTM retains relatively low RMSE

values across folds, showing its stable performance.

XGBoost’s errors are more than 5,000 kg/m

2

, high-

lighting the model’s low performance.

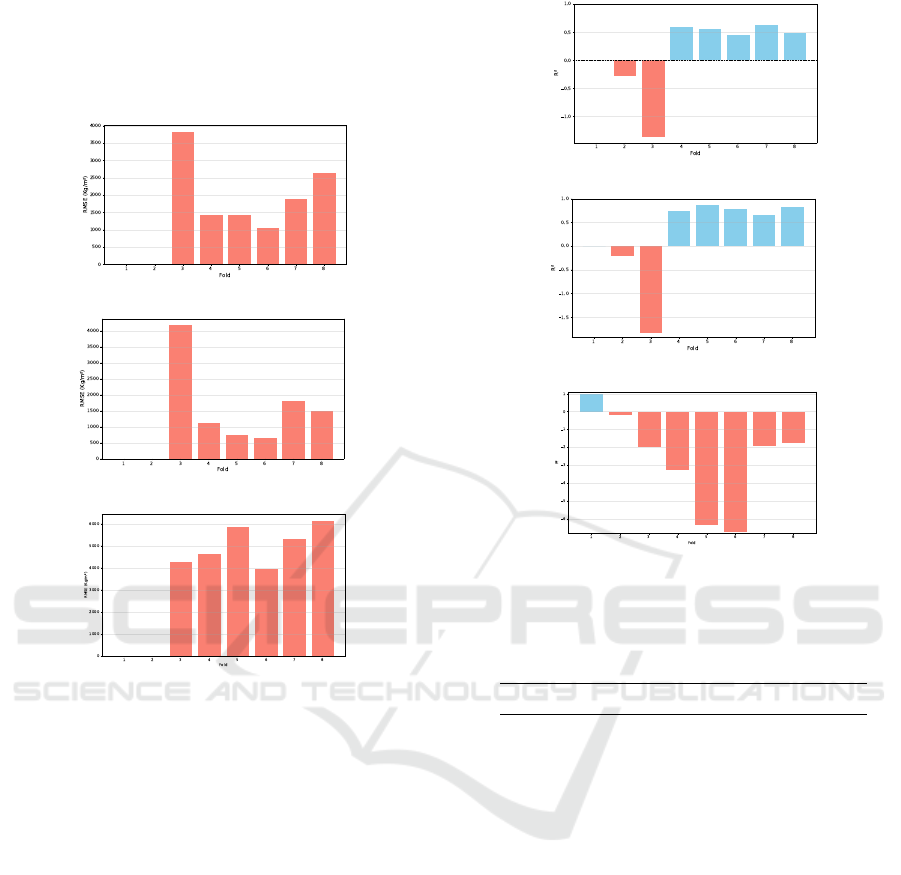

Evaluating the (R

2

) metric, LSTM attains the

highest score (0.986), slightly surpasses DNN

(0.984), and noticeably outperforms XGBoost

(0.916). Although the difference between LSTM and

DNN appears small, an inspection of the time series

predictions indicates a benefit during rapid transitions

and peak yield phases.

Figure 5 underscores that while DNN and LSTM

maintain relatively high R

2

values across folds, XG-

Boost occasionally drops into negative values, indi-

cating that the model can, in particular data splits, per-

form worse than a simple mean-based predictor.

(a) DNN.

(b) LSTM.

(c) XGBoost.

Figure 5: R

2

consistency. Negative values for XGBoost

indicate failed generalization.

Table 3: Comparative Model Performance Metrics.

Metric DNN LSTM XGBoost

MAE (kg/m

2

) 1,270.08 1,007.39 3,213.78

RMSE (kg/m

2

) 1,946.96 1,769.86 4,404.05

R

2

0.984 0.986 0.916

5.2 Edge Deployment

The final trained DNN and LSTM models were de-

ployed on an edge device, specifically a gateway

based on Raspberry Pi 4, to allow real-time yield pre-

diction at the greenhouse level. This edge deployment

guarantees localized processing of sensor data, reduc-

ing latency and dependence on cloud infrastructure

while maintaining data privacy. The TensorFlow Lite

framework was employed to convert the trained mod-

els into lightweight formats suitable for execution on

the microcontroller boards.

Both models were quantized to the Float16 preci-

sion format during conversion to reduce their size and

inference latency while maintaining nearly compara-

ble accuracy to their full-sized counterparts. Quan-

tization to Float16 reduces the memory footprint of

the models, making them favorable for edge devices.

After quantization, the size of the DNN model was

A Predictive Greenhouse Digital Twin for Controlled Environment Agriculture

985

(a) The edge gateway device used to deploy the devel-

oped models.

(b) IoT sensor nodes installed inside the greenhouse for

data collection.

Figure 6: Edge deployment setup comprising the gateway

device and greenhouse sensor nodes.

reduced from 977 KB to just 160 KB and the LSTM

model from 3.3 MB to 549 KB.

Once deployed, the Float16 quantized models pro-

cessed real-time sensor data collected from the green-

house and provided yield predictions with average in-

ference times of approximately 0.000067 seconds for

the DNN and 0.005009 seconds for the LSTM on the

Raspberry Pi.

Table 4 summarizes the performance comparison

between the quantized and full-sized models. De-

spite the significant reduction in size and latency, the

quantized models performed nearly identical predic-

tive metrics, including MAE, RMSE, and R

2

, demon-

strating their suitability for edge deployment.

Table 4: Performance Comparison: Full vs. Quantized

Models.

Metric DNN (Full / Quantized) LSTM (Full / Quantized)

Model Size (KB) 977 / 160 3,300 / 549

RMSE(kg/m

2

) 1,650.35 / 1,650.22 2,096.42 / 2,096.01

MAE(kg/m

2

) 1,163.14 / 1,162.82 1,398.72 / 1,397.39

R

2

0.984 / 0.988 0.986 / 0.981

5.3 Performance Comparison for Edge

Implementation

Table 5 compares the performance of the DNN and

LSTM models on the edge device.

Table 5: Edge Deployment Performance Comparison.

Metric DNN LSTM

RMSE(kg/m

2

) 1,650.22 2,096.01

MAE(kg/m

2

) 1,162.82 1,397.39

R

2

0.9882 0.9810

Inference Time (s) 0.000067 0.005009

The results in Table 5 illustrate the trade-offs be-

tween the DNN and LSTM models when deployed on

the Raspberry Pi 4. The DNN model exhibited faster

inference times and slightly better performance across

most metrics, including MAE, RMSE, and R

2

.

Despite the Raspberry Pi’s computational con-

straints, both models achieved real-time inference ca-

pabilities, making them suitable for edge deployment

in controlled-environment agriculture.

6 CONCLUSIONS AND FURTHER

WORK

In this study, we developed and evaluated a PGDT

for hydroponic tomato production using three differ-

ent forecasting techniques: DNN, LSTM, and XG-

Boost. Our outcomes show that LSTM consistently

outperforms DNN and XGBoost across multiple er-

ror metrics.

DNN also demonstrates good performance while

exhibiting slightly higher error rates. XGBoost trains

rapidly, and its inconsistencies in yield prediction re-

duce its reliability for real-world applications.

To further evaluate the PGDTs, we deployed the

models on an edge device (a Raspberry Pi-based

gateway), allowing real-time decision-making at the

greenhouse site without relying on cloud solutions.

While LSTM demonstrated superior accuracy, DNN

ICEIS 2025 - 27th International Conference on Enterprise Information Systems

986

emerged as a compelling alternative for edge deploy-

ment due to its significantly faster inference times and

close performance to LSTM, making DNN a better

candidate for edge implementation.

Next steps include further evaluation of the PGDT

developed in this study using synthetic data and

its integration with multi-objective optimization and

techno-economic analysis components. First, we

will develop a synthetic dataset using the greenhouse

dataset described in this paper as training material

with generative AI algorithms such as generative

adversarial networks and variational auto-encoders

and evaluate the reliance of the emerging forecasting

model using metrics such as discriminative and pre-

dictive scores (Yoon et al., 2019) (Desai et al., 2021).

Then, we will select the emerging best-in-class fore-

casting model as input to multi-objective optimization

to develop a framework that helps farmers identify

optimal resource trade-offs in securing robust crop

yields following the approach described in (Sanfil-

ippo et al., 2024). Finally, we will evaluate the eco-

nomic sustainability of optimimal trade-off scenar-

ios through techno-economic analysis, as discussed in

(Sanfilippo et al., 2024).

ACKNOWLEDGEMENTS

The authors would like to acknowledge Nasser Al-

Khalaf, Jovelyn Beltran, and Mohamed Batran at

AGRICO for their collaboration with data and setup

to conduct the study and test the systems. This

work was supported by the Ministry of Municipal-

ity and Environment (MME) under Grant MME02-

0911-200015 from the Qatar National Research Fund

(a member of Qatar Foundation) / QRDIC. The find-

ings herein reflect the work and are solely the respon-

sibility of the authors.

REFERENCES

Alhnaity, B., Pearson, S., Leontidis, G., and Kollias, S.

(2019). Using deep learning to predict plant growth

and yield in greenhouse environments. In Inter-

national Symposium on Advanced Technologies and

Management for Innovative Greenhouses: Green-

Sys2019 1296, pages 425–432.

Chen, T. and Guestrin, C. (2016). Xgboost: A scalable

tree boosting system. In Proceedings of the 22nd acm

sigkdd international conference on knowledge discov-

ery and data mining, pages 785–794.

Desai, A., Freeman, C., Wang, Z., and Beaver, I.

(2021). Timevae: A variational auto-encoder for

multivariate time series generation. arXiv preprint

arXiv:2111.08095.

Ehret, D. L., Hill, B. D., Helmer, T., and Edwards, D. R.

(2011). Neural network modeling of greenhouse

tomato yield, growth and water use from automated

crop monitoring data. Computers and electronics in

agriculture, 79(1):82–89.

Gong, L., Yu, M., Jiang, S., Cutsuridis, V., and Pearson,

S. (2021). Deep learning based prediction on green-

house crop yield combined tcn and rnn. Sensors,

21(13):4537.

Hochreiter, S. (1997). Long short-term memory. Neural

Computation MIT-Press.

Huang, J., Zhang, G., Zhang, Y., Guan, X., Wei, Y., and

Guo, R. (2020). Global desertification vulnerability to

climate change and human activities. Land Degrada-

tion & Development, 31(11):1380–1391.

Iba, W. and Langley, P. (1992). Induction of one-level de-

cision trees. In Machine learning proceedings 1992,

pages 233–240. Elsevier.

Planning, Q. and Authority, S. (2021). Qatar voluntary na-

tional review 2021. https://sustainabledevelopment.

un.org/memberstates/qatar.

Qaddoum, K., Hines, E., and Iliescu, D. (2013). Yield pre-

diction for tomato greenhouse using efunn. Interna-

tional Scholarly Research Notices, 2013(1):430986.

Sanfilippo, A., Kafi, A., Jovanovic, R., Ahmad, N., Wanik,

Z., et al. (2024). Sustainable energy management for

indoor farming in hot desert climates. Sustainable En-

ergy Technologies and Assessments, 71:103958.

Sivakumar, M. V. (2007). Interactions between climate and

desertification. Agricultural and forest meteorology,

142(2-4):143–155.

Sze, V., Chen, Y.-H., Yang, T.-J., and Emer, J. S. (2017). Ef-

ficient processing of deep neural networks: A tutorial

and survey. Proceedings of the IEEE, 105(12):2295–

2329.

Vanthoor, B., De Visser, P., Stanghellini, C., and Van Hen-

ten, E. J. (2011a). A methodology for model-based

greenhouse design: Part 2, description and validation

of a tomato yield model. Biosystems engineering,

110(4):378–395.

Vanthoor, B., Stanghellini, C., Van Henten, E. J., and

De Visser, P. (2011b). A methodology for model-

based greenhouse design: Part 1, a greenhouse cli-

mate model for a broad range of designs and climates.

Biosystems Engineering, 110(4):363–377.

Yoon, J., Jarrett, D., and Van der Schaar, M. (2019). Time-

series generative adversarial networks. Advances in

neural information processing systems, 32.

A Predictive Greenhouse Digital Twin for Controlled Environment Agriculture

987