Design of an IoT-Driven Software Architecture for an Automated

Robotic Fueling System in Open-Pit Mining

Carlos Antonio Vilchez Pascual

1 a

, Brian David Pajares Correa

2 b

and

Felix Melchor Santos L

´

opez

2 c

1

School of Science and Engineering, Pontifical Catholic University of Peru, Lima, Peru

2

Department of Engineering, Pontifical Catholic University of Peru, Lima, Peru

{cvilchezp, brian.pajares, fsantos}@pucp.edu.pe

Keywords:

IoT, ADD, Mining, Fueling, Robotic Arm.

Abstract:

The fueling process for haul trucks in open-pit mining operations is traditionally manual, leading to inefficien-

cies, operational delays, and increased costs. This paper presents the design of an automated robotic fueling

system aimed at optimizing fueling operations by automating key tasks such as fuel nozzle positioning, au-

thorization, and process monitoring. The proposed system leverages Internet of Things (IoT) technology and

a cloud-based architecture to enable real-time monitoring and seamless integration with existing mine infras-

tructure. The physical design of the system follows the German Guideline VDI 2206 methodology, while the

cloud platform is structured using the Attribute Driven Design (ADD) 3.0 methodology to ensure scalability

and adaptability. Additionally, interface prototypes were developed, including an Human-Machine Interface

(HMI) and a responsive web application, to provide real-time data visualization and operational control. The

results of this study demonstrate the potential of automation to improve fueling efficiency, enhance safety, and

reduce downtime in mining operations.

1 INTRODUCTION

The mining industry is vital to the global economy,

supplying essential minerals such as copper, gold, and

zinc. Peru ranks among the world’s top producers

of silver, copper, and zinc, with mining contributing

14.3% of its GDP and over 50% of total exports in

2019 (Walter et al., 2021).

Open-pit mining, which covers 1.47% of Peru’s

territory (MINEM, 2024), is the predominant extrac-

tion method. Ore hauling represents approximately

45% of total mining costs (Quiquia and William,

2015), making it one of the most significant expenses.

While strategies such as optimizing vehicle speed,

route planning, and acceleration management help re-

duce costs, the fueling process remains a critical bot-

tleneck in large-scale operations. Manual procedures,

including shutdown, credential logging, spill tray po-

sitioning, nozzle connection, and monitoring, intro-

duce inefficiencies, increase the risk of errors, and ex-

tend downtime.

a

https://orcid.org/0009-0001-2691-4252

b

https://orcid.org/0000-0002-4293-2151

c

https://orcid.org/0000-0001-8598-2151

This paper presents an automated fueling system

that streamlines key tasks, including nozzle position-

ing, authorization, and process monitoring (Poures-

maieli et al., 2022). The system minimizes human

intervention and optimizes fueling time through au-

tomation. Its design follows the German Guideline

VDI 2206 (Gausemeier and Moehringer, 2002) for the

physical system, while the cloud platform solution is

developed using the Attribute Driven Design (ADD)

3.0 methodology (Cervantes and Kazman, 2024) to

ensure seamless integration.

The paper reviews current fueling practices, de-

tails system design, explores cloud integration, and

introduces the user interface. It concludes by high-

lighting key features and their impact on mining op-

erations.

2 LITERATURE REVIEW

Automated fueling systems for dump trucks in min-

ing operations have advanced significantly, integrat-

ing robotics, computer vision, LiDAR sensors, and ar-

tificial intelligence (AI) to enhance efficiency, safety,

456

Vilchez Pascual, C. A., Pajares Correa, B. D. and Santos López, F. M.

Design of an IoT-Driven Software Architecture for an Automated Robotic Fueling System in Open-Pit Mining.

DOI: 10.5220/0013482500003944

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 10th International Conference on Internet of Things, Big Data and Security (IoTBDS 2025), pages 456-463

ISBN: 978-989-758-750-4; ISSN: 2184-4976

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

and precision.

Several commercial solutions have emerged to

meet industry demands. Robofuel (Scott Automa-

tion, 2023) employs a robotic arm with a 3D sensing

system to accurately position the fuel nozzle, mini-

mizing leaks and improving efficiency for haul trucks

and excavators. Pitstop (Rotec, 2025) features a hy-

draulic delta robot with an adaptive nozzle, reduc-

ing connection times to 75 seconds and disconnection

to 30 seconds, achieving a refueling speed of 1200

L/min. RAPID (Stratom, 2024) integrates LiDAR and

cameras for precise nozzle positioning, operating in

harsh mining environments at a rate of 600 gallons

per minute (GPM).

Other systems incorporate AI to optimize refuel-

ing parameters. The Fuelmatics 5000 (Auto-Energy,

2022) utilizes an XYZ positioning system with three

nozzles and vapor recovery, while the Robotic Refu-

eling System (Autofuel, 2024) includes a robotic arm

for cap opening, license plate recognition, and auto-

mated payment, making it compatible with existing

fueling stations.

Patented innovations further demonstrate progress

in this field. A multi axis robotic arm covered in

carbon fiber with a telescoping system, allowing fast

diesel fueling at up to 38 GPM while vapor cap-

ture (Hollerback, 2013). Another patent introduces a

robotic arm integrating 3D vision technology for pre-

cise fuel cap localization, improving nozzle-cap co-

ordination (Censtar Science & Technology Corp ltd,

2024). A separate patent presents a two-phase sys-

tem using industrial cameras to optimize nozzle posi-

tioning, ensuring efficient fueling across various vehi-

cle models (Hazakhstan Robotics Zhongshan Co Ltd,

2022).

Research has also contributed to system advance-

ments. Studies on industrial robots and Kinect V2

(Lam and Phung, 2021) demonstrate improved user

interface and error prevention. Vision perception

technologies, such as binocular cameras and deep

learning algorithms, have been explored to enhance

positioning accuracy and automate fueling (Guo et al.,

2021).

These innovations not only improve the precision

and safety of fueling haul trucks but also create op-

portunities for broader industrial applications, driving

further advancements in automation (Bi et al., 2021).

3 SYSTEM PROPOSAL

The proposed autonomous robotic fueling system,

shown in Figure 1, is designed to optimize refueling

for mining dump trucks in open-pit environments. It

connects and disconnects the fuel nozzle in approx-

imately 56 seconds, improving efficiency and reduc-

ing downtime. Compared to Pitstop, which requires

75 seconds for connection and 30 seconds for discon-

nection (Rotec, 2025), the proposed system reduces

total fueling time by nearly 33%, further enhancing

operational performance.

A key component is the robotic arm, which pro-

vides extended reach, high precision, and repeatabil-

ity. To ensure reliability in harsh mining conditions,

it is enclosed in a protective cabin that shields it from

dust, debris, and extreme temperatures. Structural

components are made of stainless steel 304, offering

high resistance to corrosion and mechanical wear, en-

hancing durability and operational lifespan.

This section details the robotic arm configuration

and its controller, followed by the mechanical and

electronic design of the automatic connection tool for

precise fuel nozzle attachment. The electrical panel

design is then examined, covering energy supply, con-

trol, data processing, and communication. Finally, the

monitoring interface and signaling systems that en-

sure operational safety are introduced.

Figure 1: Perspective-isometric view of the Automated Fu-

eling System.

3.1 Robotic Arm Configuration

The selection of the robotic arm was based on an

analysis of dimensional reach and load capacity re-

quirements. A reach of 2902 mm was determined af-

ter evaluating various dump truck models, ensuring a

minimum safety distance. The estimated load capac-

ity, based on the preliminary design of the connection

tool, was approximately 60 kg.

Given these requirements, the KUKA KR-120

3100 F was chosen for its ability to meet both reach

and load demands. Its foundry configuration en-

sures reliable operation in harsh environments, fea-

turing IP65 protection for the structure and IP67 at

Design of an IoT-Driven Software Architecture for an Automated Robotic Fueling System in Open-Pit Mining

457

the end effector, providing resistance to dust and wa-

ter ingress. With a repeatability of ±0.05 mm, it deliv-

ers consistent performance over prolonged operations

and across large fleets.

The arm is managed by the KR-C5 control sys-

tem, housed in a Basic Cab configuration, enabling

full operational control.

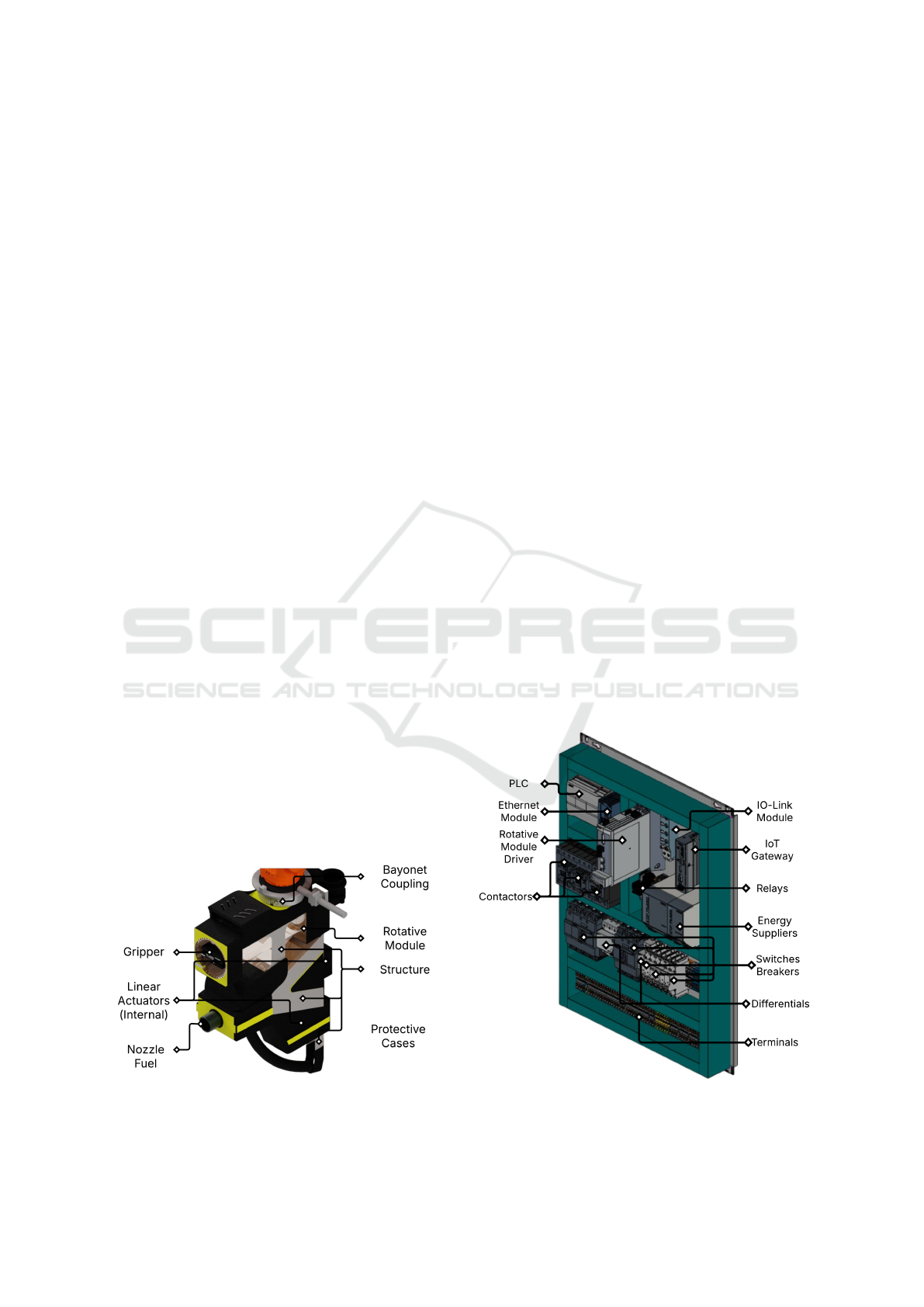

3.2 Automatic Connection Tool

An automatic connection tool, shown in Figure 2, was

designed to ensure a precise and reliable connection

between the fuel nozzle and the fuel tank.

At the core of the system’s automated position-

ing is a 3D vision system with high spatial resolu-

tion, operating alongside an industrial PC responsi-

ble for processing tank cap position calculations via a

pose estimation algorithm. Image data is transferred

at high speed using 10GigE Ethernet technology, en-

abling computations in under 2 seconds. The pro-

cessed spatial data is then sent to the robotic controller

for precise tool positioning.

The connection process follows three distinct

phases to ensure accuracy and efficiency. In the first

phase, a gripper secures the fuel tank’s screw cap

while a rotary module applies the required torque for

removal. In the second phase, the fuel nozzle is posi-

tioned using a linear actuator, which moves it 50 mm

horizontally along precision-guided ball rails. The fi-

nal phase initiates fuel flow by lifting the nozzle lever

with another linear actuator, supported by an inter-

nally designed mechanism. Disconnection follows

the same sequence in reverse.

To protect internal components, a robust protec-

tive casing shields the tool from dust, moisture, and

mechanical impacts, ensuring durability in harsh en-

vironments. Finally, the tool is securely attached to

the robotic arm’s end effector using a bayonet cou-

pling, enabling quick and reliable installation.

Figure 2: Isometric view of the Automatic Connection Tool.

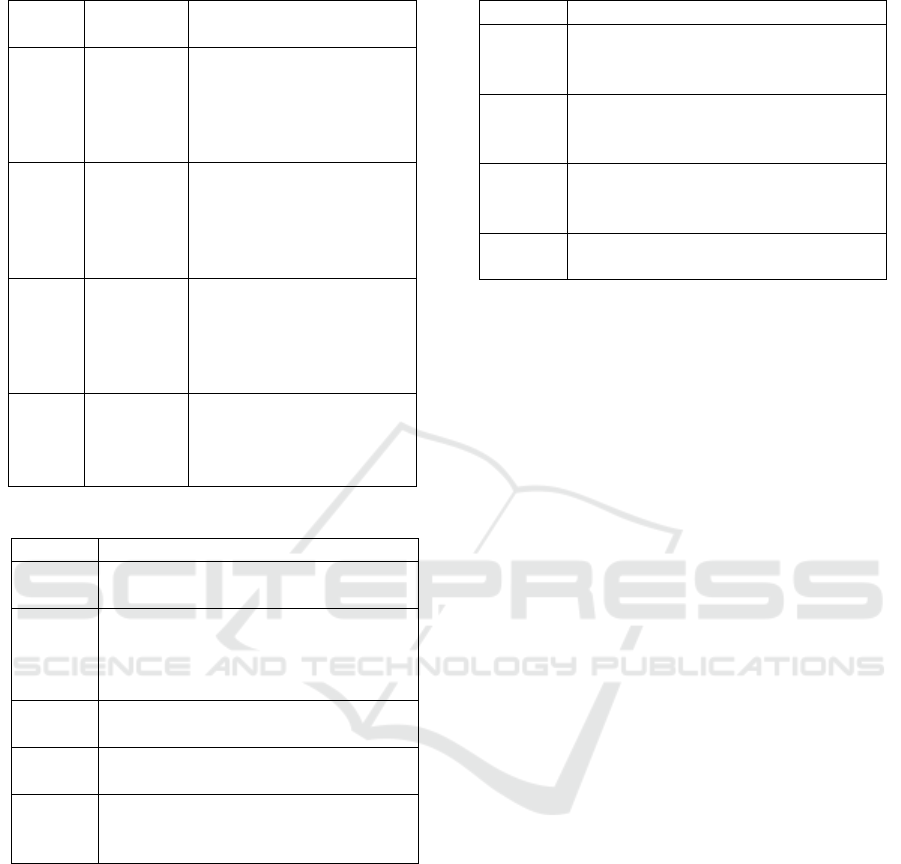

3.3 Electrical Panel

The electrical panel, illustrated in Figure 3, is housed

in a protective enclosure (600×800×400 mm) and

contains the essential components for energy protec-

tion, control, supply, data processing, and communi-

cation.

For energy protection, the panel includes differ-

ential and circuit breakers, ensuring safe power dis-

tribution across the system with 40 A, 20 A, 10 A,

and 6 A outputs. Energy control and supply are man-

aged using industrial contactors and regulated power

supplies, delivering stable power to DC devices, in-

cluding linear actuators.

A programmable logic controller (PLC) governs

system operation, managing control via I/O interfaces

and Ethernet ports. Relay outputs are connected to

intermediary relays for safe contactor control, while

dedicated inputs handle start, stop, and emergency

stop functions. The panel also houses a servo drive,

responsible for regulating the rotary module.

For connectivity and expandability, the panel in-

tegrates an Ethernet switch, allowing the PLC to ex-

pand its network connections. An IO-Link module

connects components such as the gripper and tower

lamp, while an industrial IoT gateway centralizes data

for cloud processing.

The panel is designed for an organized layout,

incorporating structured wiring distribution and ded-

icated terminal blocks for earth, neutral, and relay

connections, ensuring efficient operation and mainte-

nance.

Figure 3: Internal isometric view of the Electrical Panel.

IoTBDS 2025 - 10th International Conference on Internet of Things, Big Data and Security

458

3.4 Monitoring and Signaling

Process data, including fuel level, filling velocity, user

information, and operational stage, is displayed on

a human-machine interface (HMI), allowing the fuel

station operator to monitor fueling in real-time. The

HMI communicates with the PLC via an Ethernet

connection, ensuring accurate process tracking and

seamless data exchange.

System status signaling is managed by a tower

lamp, which provides visual and auditory alerts

throughout the fueling process. The lamp emits inter-

mittent lighting and audible alarms to indicate system

operation and is controlled by the PLC via an IO-Link

interface, ensuring timely and reliable signaling.

4 CLOUD-PLATFORM

SOLUTION DESIGN

The development of the system requires a platform

capable of monitoring the entire operation in real

time. This is achieved through the design of a cloud

platform architecture that leverages Internet of Things

(IoT) sensors integrated into the system. The design

process is carried out using the ADD 3.0 methodol-

ogy, which is structured into seven systematic steps.

Before initiating the design process, it is necessary to

define the architectural drivers, including use cases,

quality attributes, architectural constraints, and ar-

chitectural concerns, as a foundational prerequisite

(L

´

opez et al., 2021; Ruiz-Navarro et al., 2021).

4.1 Architectural Drivers

User cases

The functional requirements represent the specific

capabilities or functionalities that the system must de-

liver. These requirements are defined and detailed

through use cases, as outlined in Table 1.

Quality Attributes

These are measurable characteristics of interest to

users that define how effectively the system performs

its functions. They are outlined in Table 2.

Architectural Constraints

These are restrictions or limitations imposed on

the architecture. Constraints may arise from business

decisions, regulatory requirements, or legacy systems.

In this design process, they primarily reflect technical

choices, as presented in Table 3.

Architectural Concerns

These represent the interests, needs, and expec-

tations of all stakeholders involved in the system, as

outlined in Table 4.

Table 1: Use Case Description.

ID User Case Description

UC-1

Authenticate

User

The user authenticates in

the system to access the

functions of the

automated system.

UC-2

Start Filling

Cycle

The truck operator starts

the fuel filling cycle in

the system.

UC-3

Stop Filling

Cycle

The truck operator stops

the fuel filling cycle

upon completing the

process or in case of

emergency.

UC-4

Record

Incident

The operator or the

system records an

incident occurring

during the filling or

maintenance process.

UC-5

Generate

Automatic

Mainte-

nance

The system detects and

automatically schedules

maintenance based on

incidents or alerts

generated during the

filling cycle.

UC-6

Generate

Manual

Mainte-

nance

The administrator or

station supervisor can

manually create a

maintenance request for

the equipment or

system.

UC-7

Generate

Operation

Report

The system generates a

detailed report of

operations, including

fillings, incidents, and

recorded maintenances.

4.2 Design Process

The previously defined architectural drivers are used

to iteratively design the architecture, as outlined in the

following sections.

4.2.1 Architectural Priorities: Input Review,

Goal Definition, and Element Selection

Following the ADD 3.0 methodology, the initial steps

establish a solid architectural foundation. Step 1 re-

views and validates architectural drivers to ensure

alignment with system objectives. Step 2 defines the

iteration’s goal, addressing all drivers to finalize the

architecture in a single cycle. Step 3 selects and

refines key components, ensuring the architecture is

fully developed within this iteration.

Design of an IoT-Driven Software Architecture for an Automated Robotic Fueling System in Open-Pit Mining

459

Table 2: Quality Attributes Scenarios.

ID

Quality

Attribute

Scenario

QA-1 Security

A user attempts to access

the system without valid

credentials, and the

system denies access

100% of the time.

QA-2 Reliability

The operator wants to

manually record an

incident, and the system

generates it correctly

100% of the time.

QA-3 Reliability

The system automatically

generates a maintenance

request correctly 100%

of the time when there is

a critical system incident.

QA-4 Reliability

The administrator

generates a maintenance

request correctly 100%

of the time.

Table 3: System Constraints.

ID Constraint

CON-1

Use AWS as the cloud service

provider for the deployment model.

CON-2

Access to the monitoring system

must be through a web browser

using a device connected to the

mine’s Wi-Fi network.

CON-3

Use a communication protocol

oriented to IoT.

CON-4

Use an IoT-oriented reference

architecture based on AWS services.

CON-5

Use a relational database for

compatibility with the mine’s

database.

4.2.2 Design Concept Selection to Satisfy

Architectural Driverss

As part of step 4, the architectural design and host-

ing decisions follow an IoT service-oriented archi-

tecture optimized for real-time monitoring and con-

trol. Sensor data is collected through a robust con-

trol system, processed efficiently, and displayed via

a user-friendly web application while generating de-

tailed incident logs during fuel-filling operations. To

meet these requirements, the following AWS-based

services were selected:

Smart Farm on AWS Reference Architecture

(AWS, 2024a) was selected for its IoT compatibil-

Table 4: System Concerns.

ID Concern

CRN-1

Ensure compatibility with existing

equipment and technology in the

mining environment.

CRN-2

Design the system based on

modularity criteria to facilitate

updates and maintenance.

CRN-3

Ensure proper management of

incident records for compatibility

with the mine’s database.

CRN-4

Ensure real-time information

processing.

ity (CON-3), seamless AWS integration, and real-

time processing (CRN-4). Its modular design en-

sures interoperability with mining equipment (CRN-

1) and simplifies maintenance (CRN-2). It also pro-

vides secure access control (QA-1) and reliable in-

cident logging with automated maintenance (QA-2,

QA-3). Alternatives like Siemens Industrial Edge

on AWS (AWS, 2024b), Connected Restaurants Us-

ing IoT, AI & ML (AWS, 2022), and Edge Inference

for Agriculture (AWS, 2020) were discarded due to

misalignment with fuel monitoring, unnecessary edge

processing, and higher costs.

Edge Computing minimizes latency by process-

ing data locally, enabling real-time monitoring and in-

stant responses to critical events (UC-2, UC-3, UC-

4). It leverages IoT protocols (CON-3) and integrates

with AWS IoT Greengrass (CON-4) for scalable, ro-

bust processing.

IoT Device Management Platform enables

seamless cloud connectivity, real-time data exchange,

and efficient incident management. It supports pre-

dictive maintenance, device configuration, and diag-

nostics to ensure operational continuity (UC-4, UC-

5). Compliant with IoT protocols (CON-3), it lever-

ages AWS IoT Core for centralized management

(CON-4).

Data Storage securely manages incident logs,

sensor data, and reports, ensuring scalability and

accessibility for analysis (UC-4, UC-7). AWS S3

provides cost-efficient storage while complying with

AWS security protocols (CON-1).

Data Visualization Tools provide intuitive inter-

faces for analyzing operational data, improving sys-

tem health and performance insights (UC-7). AWS

QuickSight powers dynamic dashboards for action-

able decision-making (CON-1).

Event-Driven Code Execution automates actions

like maintenance alerts and safety responses (UC-4,

UC-5). AWS Lambda ensures efficient, reliable event

processing (CON-1, CON-3).

IoTBDS 2025 - 10th International Conference on Internet of Things, Big Data and Security

460

Centralized Security Alerts coordinate re-

sponses to security threats, protecting system access

and data (UC-1, CON-2). AWS IoT Device Defender

monitors and mitigates vulnerabilities.

Real-Time Notifications alert users about inci-

dents and maintenance needs, ensuring prompt re-

sponses and operational efficiency (UC-4, UC-6).

AWS SNS guarantees reliable, immediate message

delivery (CON-1).

Application Programming Interface (API)

Communication Interface enables secure, reliable

integration between the web application and backend

services (UC-1, UC-2, UC-6). It adheres to indus-

try standards and ensures consistent data exchange via

Wi-Fi (CON-2).

A relational Cloud Database Service was selected

to ensure compatibility with the mine’s existing re-

lational database (CON-5). This choice enables

structured management of incident logs and opera-

tional data, ensuring integrity and consistency (CRN-

3). The cloud-based approach provides scalability,

high availability, and fault tolerance, supporting real-

time processing and seamless integration with local

databases (CRN-4). A secure endpoint will facili-

tate reliable data exchange between the cloud and on-

premise infrastructure via the system’s API.

4.2.3 Instantiation of Architectural Elements

As part of step 5, the following design decisions in-

stantiate the architectural elements to meet system re-

quirements.

AWS IoT Greengrass enables local machine

learning and data processing, collecting sensor data

and responding to critical events in real time. This

minimizes latency and reduces dependency on con-

stant server connectivity (UC-2, UC-3, UC-4). It ad-

heres to IoT protocols (CON-3), integrates with AWS

architecture (CON-4), and ensures reliability and se-

curity (QA-2, QA-3).

AWS IoT Core manages IoT devices and com-

munication via MQTT, ensuring reliable data trans-

mission for incident detection and management (UC-

4, UC-5). It complies with IoT protocols (CON-3),

integrates with AWS architecture (CON-4), and pri-

oritizes reliability and security (QA-2, QA-3).

Amazon S3 securely stores incident logs, reports,

and maintenance records, ensuring scalable and ac-

cessible data management (UC-4, UC-7). It complies

with AWS restrictions (CON-1) and Wi-Fi access

(CON-2), prioritizing security and reliability (QA-

1). Amazon QuickSight provides interactive visual-

izations for data-driven decision-making (UC-7), ad-

hering to AWS restrictions (CON-1) and ensuring re-

liability (QA-2).

AWS Lambda automates critical tasks by pro-

cessing sensor data, detecting incidents, and trigger-

ing maintenance (UC-4, UC-5). It retrieves and pre-

pares data from the mine database via API Gateway,

ensuring seamless integration for analysis and visu-

alization. This service adheres to AWS standards

(CON-1), supports IoT protocols (CON-3), and en-

hances reliability and security (QA-2, QA-3).

AWS Security Hub centralizes security alerts,

protecting against unauthorized access and ensuring

data integrity (UC-1). It complies with Wi-Fi secu-

rity protocols (CON-2) and prioritizes robust security

measures (QA-1).

Amazon SNS delivers real-time notifications to

users about incidents or maintenance, improving op-

erational response times (UC-4, UC-6). This service

adheres to AWS restrictions (CON-1), emphasizing

reliability and security (QA-1, QA-3).

Amazon API Gateway ensures secure, efficient

communication between the web application, back-

end services, and the mine database via a dedi-

cated endpoint. It enables seamless access to sys-

tem functionalities (UC-1, UC-2, UC-6) with secure

Wi-Fi connectivity (CON-2) while ensuring real-time

data availability (CRN-4) and compatibility (CON-

5). Acting as a secure intermediary, it facilitates ef-

ficient data exchange between local and cloud-based

systems.

AWS DynamoDB was chosen for its compatibil-

ity with the mine’s database (CON-5) and efficient in-

cident management (CRN-3). Its scalability ensures

real-time processing and peak performance (CRN-

4). Integration with AWS Lambda and IoT Core en-

hances reliability (QA-2, QA-4), while its NoSQL ar-

chitecture enables flexible data storage.

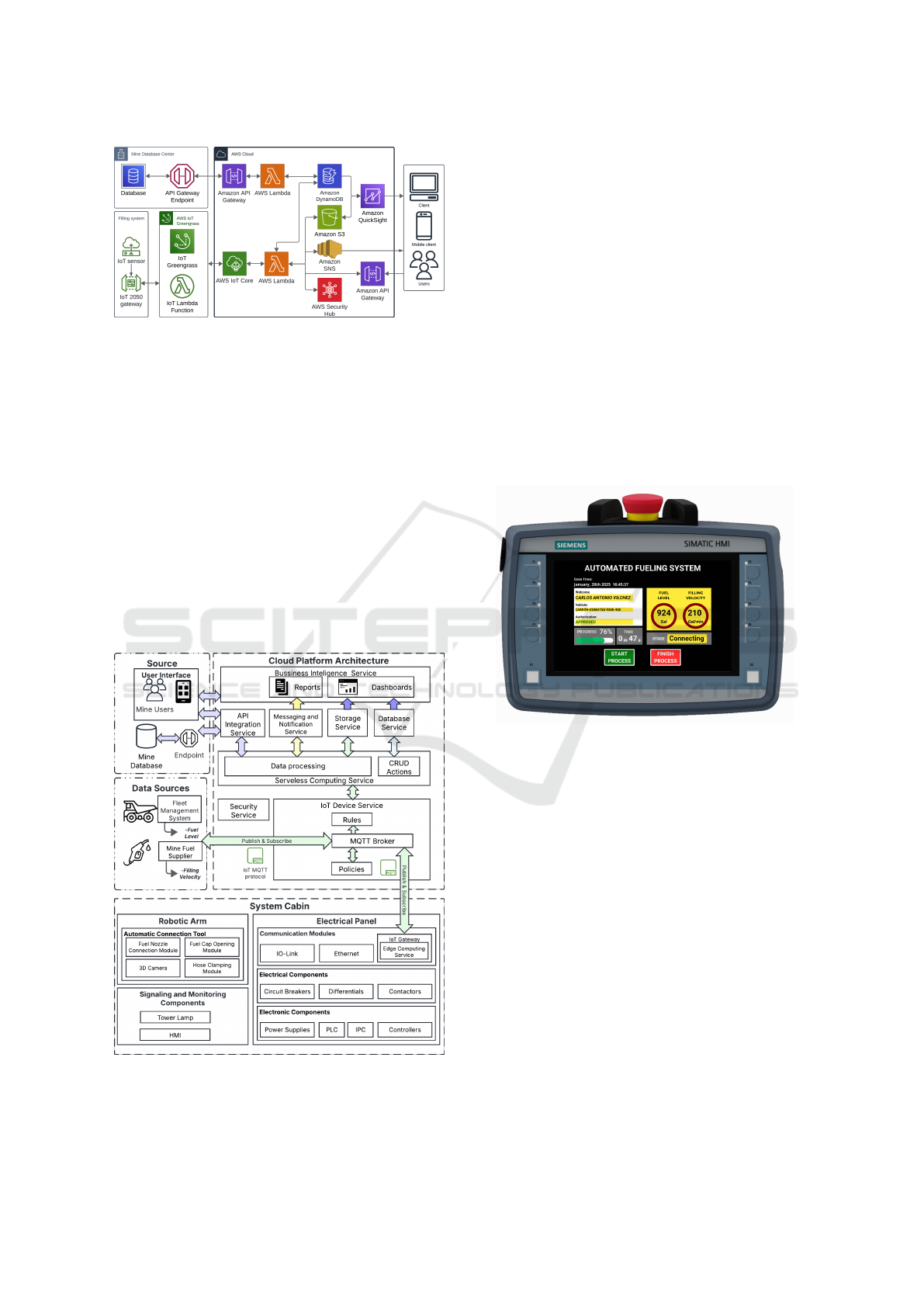

4.2.4 Design Visualization and Evaluation

Upon completing the previous steps, step 6 illustrates

the final architecture in Figure 4. In step 7, a com-

prehensive evaluation of steps 1 to 6 confirmed that

the established goal was successfully achieved. This

iteration effectively addressed the primary functional-

ities, quality attributes, architectural constraints, and

concerns, ensuring the completeness of the cloud plat-

form architecture design process. For brevity, the

Kanban board has been omitted.

5 INTEGRATION

The AWS-based cloud architecture enables real-time

monitoring of the automated fueling process, integrat-

ing the physical system, data sources, and end users

Design of an IoT-Driven Software Architecture for an Automated Robotic Fueling System in Open-Pit Mining

461

Figure 4: Cloud-Platform architecture diagram.

through IoT technology. As illustrated in Figure 5,

data from the fleet management system and fuel sup-

pliers is transmitted via IoT MQTT protocols to the

cloud, where it is processed, stored, and made avail-

able for analysis. The system connects to a central-

ized mine database through an API integration ser-

vice, ensuring secure data retrieval and storage.

Mine operators can access the system via a dedi-

cated user interface, which provides real-time insights

through reports and dashboards generated by the busi-

ness intelligence service. This interface allows users

to monitor fueling operations, track key performance

indicators, and respond to alerts efficiently.

Inside the system cabin, the robotic arm, electri-

cal panel, and monitoring components operate in syn-

chronization to optimize fueling.

Figure 5: System Integration Diagram.

6 INTERFACE PROTOTYPING

Following the design process, the prototyping phase

focused on developing user interfaces for the auto-

mated fueling system, accessible via the SIMATIC

KTP700 Mobile HMI and a responsive web applica-

tion.

The HMI interface (Figure 6) provides on-site op-

erators with real-time data, including credentials, ve-

hicle ID, fuel level, fill velocity, and process status.

Intuitive action buttons streamline operation, mini-

mizing errors.

The web application offers remote access from

mobile and desktop devices, mirroring HMI func-

tionalities such as authorization status, vehicle de-

tails, and process tracking. Cloud integration ensures

secure, real-time synchronization, enabling fueling

management from any location.

Figure 6: HMI interface Mockup.

7 CONCLUSIONS

This paper presents the design of an automated

robotic fueling system for haul trucks in open-pit min-

ing, addressing inefficiencies in the manual fueling

process. The proposed system automates key tasks

such as fuel nozzle positioning, authorization, and

process monitoring, improving operational efficiency

and reducing downtime.

The system design integrates IoT technology

and a cloud-based platform, ensuring seamless com-

munication between physical components and data

sources. The implementation of the VDI 2206

methodology for the physical system and ADD 3.0

methodology for the cloud platform enabled a struc-

tured and scalable approach. The developed interface

prototypes, including an HMI and a responsive web

application, provide operators with real-time monitor-

ing and control capabilities, enhancing usability and

IoTBDS 2025 - 10th International Conference on Internet of Things, Big Data and Security

462

accessibility.

As a next step, future work should focus on the

implementation of the cloud platform to validate the

proposed ADD 3.0 design and assess its performance

in real-world conditions. Further enhancements, such

as predictive maintenance integration, could improve

system reliability and scalability.

Overall, the proposed system demonstrates a vi-

able solution for optimizing fueling operations in

mining environments, offering potential for broader

industrial applications.

REFERENCES

Auto-Energy (2022). Automatic refueling technology.

https://autoenergy.se/products/fuelmatics/.

Autofuel (2024). Automatic refueling. https://autofuel.eu/.

AWS (2020). Edge Inference for Agri-

culture. https://d1.awsstatic.com/

architecture-diagrams/ArchitectureDiagrams/

edge-inference-for-agriculture-ra.pdf?did=wp card&

trk=wp card.

AWS (2022). Connected Restaurants using

IoT and AI/ML. https://d1.awsstatic.com/

architecture-diagrams/ArchitectureDiagrams/

connected-restaurants-using-iot-ai-ml-ra.pdf?did=

wp card&trk=wp card.

AWS (2024a). Farm on Amazon Web Services.

https://docs.aws.amazon.com/architecture-diagrams/

latest/smart-farm-on-aws/smart-farm-on-aws.html.

AWS (2024b). Integrate Siemens Industrial Edge

with AWS IoT Sitewise. https://d1.awsstatic.

com/architecture-diagrams/ArchitectureDiagrams/

siemens-industrial-edge-on-aws-ra.pdf.

Bi, Z., Luo, C., Miao, Z., Zhang, B., and Zhang,

C. W. J. (2021). Automatic robotic recharging

systems – development and challenges. Indus-

trial Robot, 48(1):95–109. https://doi.org/10.1108/

IR-05-2020-0109.

Censtar Science & Technology Corp ltd (2024). Auto-

matic robot refueling device and refueling method

(CN114195083A). https://patents.google.com/patent/

CN114195083A/en.

Cervantes, H. and Kazman, R. (2024). Designing software

architectures: a practical approach. Addison-Wesley

Professional.

Gausemeier, J. and Moehringer, S. (2002). VDI 2206- A

New Guideline for the Design of Mechatronic Sys-

tems. IFAC Proceedings Volumes, 35(2):785–790. 2nd

IFAC Conference on Mechatronic Systems, Berkeley,

CA, USA, 9-11 December.

Guo, L., Liu, K., Zhang, L., Zhang, Y., Tian, Y., and Zhang,

J. (2021). Research on vision perception technol-

ogy of auto fueling robot on opencv-based gas tank

cap recognition. Journal of Physics: Conference

Series, 1952(2):022067. https://dx.doi.org/10.1088/

1742-6596/1952/2/022067.

Hazakhstan Robotics Zhongshan Co Ltd (2022). Au-

tomatic refueling equipment and automatic refu-

eling system for automobile (CN111573608A).

https://patents.google.com/patent/CN111573608A/

en?oq=CN111573608A.

Hollerback, J. A. (2013). Automated vehicle fuel-

ing apparatus and method (US8393362B1).

https://patents.google.com/patent/US8393362B1/

en?oq=US8393362B1#citedBy.

Lam, C. T. and Phung, T. C. (2021). Research on applica-

tion of industrial robots in automated fueling systems

for small individual cars. VNUHCM Journal of Engi-

neering and Technology, 4(3):1057–1067.

L

´

opez, F. M. S., Delgado, J. M. P., De la Cruz, E. G. S.,

and C

´

aceres, E. L. (2021). Performance-based soft-

ware architecture design and blockchain as a service

for peruvian e-government. In 2021 IEEE 12th In-

ternational Conference on Software Engineering and

Service Science (ICSESS), pages 1–5. IEEE.

MINEM (2024). Actualizaci

´

on de la cartera de

proyectos de inversi

´

on minera. https://www.

gob.pe/institucion/minem/informes-publicaciones/

5374641-boletin-estadistico-minero-enero-2024.

Pouresmaieli, M., Ataei, M., and Taran, A. (2022). Future

mining based on internet of things (iot) and sustain-

ability challenges. International Journal of Sustain-

able Development & World Ecology, 30(2):211–228.

https://doi.org/10.1080/13504509.2022.2137261.

Quiquia, M. and William, G. (2015). Mejoramiento con-

tinuo en la gesti

´

on del ciclo de acarreo de camiones

en miner

´

ıa a tajo abierto en Antamina, Cerro Verde,

Toquepala, Cuajone, Yanacocha, Alto Chicama, Las

Bambas, Cerro Corona, Antapacay y Pucamarca. http:

//hdl.handle.net/20.500.14076/2181.

Rotec (2025). Robotic fuelling system for haul

trucks, mining trucks, trains and agvs.

https://rotec-engineering.nl/robotic-fuelling-systems/

robotic-fuelling-system-for-haul-trucks/.

Ruiz-Navarro, J. A., Santos-L

´

opez, F. M., Portella-Delgado,

J. M., and Santos-de-la Cruz, E. G. (2021). Computer

vision technique to improve the color ratio in estimat-

ing the concentration of free chlorine. In Interna-

tional Conference on Computer Science, Electronics

and Industrial Engineering (CSEI), pages 127–141.

Springer.

Scott Automation (2023). https://scottautomation.com/en-

us/products/mining/mining-field-

automation/robofuel.

Stratom (2024). Rapid refueling, recharging and liq-

uid transfer system. https://www.stratom.com/

rapid-stratoms-autonomous-refueling-recharging-and

-liquid-transfer-system/.

Walter, M., De Pi

´

erola, J. C., Cooper, C., Zegarra, D.,

Diez Canseco, C., Gobitz, V., Laguna, R., and Liendo,

C. (2021). Miner

´

ıa en Per

´

u 2021-2030:¿ Qu

´

e rol juega

en la reactivaci

´

on econ

´

omica y el desarrollo territorial.

Estudio y recomendaciones sectoriales. Banco Inter-

americano de Desarrollo.

Design of an IoT-Driven Software Architecture for an Automated Robotic Fueling System in Open-Pit Mining

463