Centre for Energy and Environmental Technologies – Explorer

(CEETe): Advanced Scientific Perspectives and Applications

Stanislav Misak

1a

, Lukas Prokop

1b

, Vojtech Blazek

1c

, Ivo Pergl

1

and Mohit Bajaj

1,2,3

1

ENET Centre, CEET, VSB-Technical University of Ostrava, 17. listopadu 2172/15, Ostrava-Poruba, 708 00, Czechia

2

Hourani Center for Applied Scientific Research, Al-Ahliyya Amman University, Amman, Jordan

3

Department of Electrical Engineering, Graphic Era (Deemed to be University), Dehradun, 248002, India

Keywords: CEETe, Research Platform, Energy Communities.

Abstract: The Centre for Energy and Environmental Technologies – Explorer (CEETe) is a research platform combining

research and development of cross-sectoral cooperation in sustainable energy, aiming to transfer innovative

technologies to ensure energy self-sufficiency and raw material independence in the European context. Its

interdisciplinary approach enables the efficient decarbonisation of industrial processes, the optimisation of

the use of renewable energy sources and the implementation of circular economic models. CEETe's research

activities include advanced energy technologies and environmental processes, with key areas being

combustion modelling, hydrogen technology development and energy storage. The Centre is actively involved

in international research projects and technology transfer to industry. This article provides an overview of the

key research areas, current projects and future directions of CEETe's scientific activities, emphasising the

integration of advanced technological solutions for sustainable energy and environmental management.

1 INTRODUCTION

The Centre for Energy and Environmental

Technologies – Explorer (CEETe) is an

interdisciplinary research platform within the VSB-

Technical University of Ostrava (VSB-TUO). The

primary research focuses on advanced technologies in

energy and environmental processes, emphasizing the

development of innovative and sustainable solutions

for the decarbonizing industry and the efficient

utilization of renewable energy sources. The Centre

addresses global challenges related to transforming

energy systems, promoting a circular economy, and

optimizing water and material management. The

primary research focuses on advanced technologies in

energy and environmental processes, emphasizing the

development of innovative and sustainable solutions

for the decarbonizing industry and the efficient

utilization of renewable energy sources. The Centre

addresses global challenges related to transforming

energy systems, promoting a circular economy, and

optimizing water and material management. The

a

https://orcid.org/0000-0002-7344-6930

b

https://orcid.org/0000-0003-0495-5499

c

https://orcid.org/0000-0003-0508-8518

foundation stone of the CEETe polygon was laid on

18 February 2022. After a year and a half of intensive

work, the polygon was launched in October

2023.(Misak Stanislav et al., 2024)

In line with the principles of technological

innovation and environmental sustainability, the

CEETe research platform formulates the following

scientific objectives:

Advanced development of energy systems: -

optimisation of technologies for efficient energy

conversion, storage and distribution

Minimisation of environmental externalities -

implementation of innovative methods to reduce

industrial emissions and ecological impacts.

Renewable energy integration - modelling and

simulation of energy networks with a high share

of renewable technologies.

Industrial cooperation and technology transfer -

application of research outputs in industrial

sectors to decarbonise production processes.

The CEETe research platform was designed using

a digital twin, enabling precise modelling, simulation,

Misak, S., Prokop, L., Blazek, V., Pergl, I. and Bajaj, M.

Centre for Energy and Environmental Technologies – Explorer (CEETe): Advanced Scientific Perspectives and Applications.

DOI: 10.5220/0013504600003953

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 14th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2025), pages 215-221

ISBN: 978-989-758-751-1; ISSN: 2184-4968

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

215

and optimisation of its energy systems before

physical implementation. This approach allowed for

detailed analysis of energy flows, component

interactions, and operational scenarios, ensuring

optimal integration of renewable energy sources,

battery storage, and microgrid systems. Figure 1 and

Figure 2 show CEETe's digital twin.

Figure 1: CEETe's Digital Twin.

Figure 2: Detail of CEETe's Digital Twin.

CEETe provides an environment for experimental

validation of power management and generation

models under realistic conditions. Within this

platform, the following key elements have been

implemented and tested:

Renewable Energy Integration - CEETe

includes the operation of photovoltaic power

plants (PV) and other decentralised sources that

are key to testing models for energy production

and consumption management.

Energy Resource Flexibility Analysis—The

platform simulates various operational

scenarios, including controlled charging and

discharging of battery storage and real-time

prediction of its availability.

EV charging optimisation - Telematics data and

predictive models allow efficient charging cycle

management to maximise the use of PV energy

and minimise grid draw.

Dynamic energy flow management—The

developed analytical tools monitor and optimise

energy flows between generation sources,

storage, and consumption in real-time.

Testing of decision-making algorithms - CEETe

serves as a testbed for implementing and

validating the developed models for community

energy management and their integration into

real energy systems.

The early first results achieved within the CEETe

research platform confirm the potential of community

energy for efficiently managing distributed energy

systems. Combining renewables, storage, and

intelligent consumption management is key to

achieving higher energy self-sufficiency and reduced

operating costs.

In the future, CEETe is envisaged as an active

energy component of the VSB-TUO campus. It will

optimise energy flows within the university

infrastructure, including managing individual

building consumption and integrating the electric

vehicle fleet. This approach will enable more efficient

use of renewable resources, reduce the campus

carbon footprint, and create a model environment for

the future development of decentralised energy

communities.

VSB-TUO has seven faculties and two research

centres. The campus houses the Rector's Office

building, where laboratories and classrooms are

located. In the central part of the campus are

laboratory facilities, a library, a canteen, CEETe and

a kindergarten. This part is connected to the sports

facilities and the student dormitory buildings close to

the complex. The campus has many modern research

centres, and several buildings have won awards. The

university campus thus offers maximum comfort, the

complex is also close to public transport, has plenty

of parking space, and is connected to the forest park.

The total area of the campus is 39.7 hectares, and the

total electricity consumption is 2 GW∙h. A photo of

the campus of the VSB-TUO can be seen in

Figure 3

.

Figure 3: Campus VSB-TUO.

SMEN 2025 - Special Session on Smart City and Smart Energy Networks

216

The CEETe project's next phase will extend the

test platform with new functionalities, including

developing decentralised energy communities,

advanced management of peer-to-peer energy

transactions and implementing blockchain

technologies to ensure transparency and security of

energy distributions. The outputs of this phase will

contribute to developing a scalable and replicable

community energy model with direct application in

industrial practice and urban energy systems—a

photo of the CEETe is show in Figure 4.

Figure 4: CEETe (CEET Website, 2025).

The article's primary goal is to introduce the

potential of CEETe, like technological infrastructure

and its role in developing and advancing microgrid

management, renewable energy integration, and

intelligent energy storage. Furthermore, CEETe can

optimise energy flows, enhance grid resilience, and

reduce carbon footprint through advanced control

algorithms and real-time energy management.

Additionally, the article explores future applications of

CEETe within the VSB-TUO campus, positioning it as

a model for decentralised energy systems and smart

community energy management. (Blažek, 2024)

2 ENERGY INFRASTRUCTURE

OF CEETe BUILDING

CEETe energy management is based on modified

Schneider Electric's comprehensive EcoStruxure™

Microgrid Advisor (EMA) system, which enables

advanced real-time control of electricity generation,

storage and consumption. This system significantly

reduces operating costs and carbon dioxide emissions

by optimising energy use from local sources and

minimising the demand on the grid. A key feature is

the ability to operate autonomously and 'start from

dark', so if the external grid fails, the building can

immediately switch to off-grid mode and provide a

stable electricity supply for key technologies.

The system covers smooth transitions between

parallel and off-grid operation, regulating both

voltage and frequency so that the operation does not

suffer outages or performance degradation at any

stage. The power solution also includes a peak load

management mechanism that continuously evaluates

current demand and renewable resource availability

and balances any imbalances between generation and

consumption through battery storage. These features

ensure high power reliability while ensuring efficient

energy management.

The basis of the local electricity generation is a

photovoltaic system comprising 473 panels (type

JAM60S21-370/MR from JA Solar Holdings Co.,

Ltd.) with a total area of 883.7 m², which are placed

on the roof and facades of the building in the east,

south and west directions. Optimisers have been

installed to maximise efficiency. The resulting system

has a projected annual specific energy gain of 516.3

kW∙h∙kWp

-1

and an annual production of

approximately 90.505 MW∙h. The complex also

includes a 500-kW∙h battery storage facility with a

250 kVA Schneider Electric inverter and batteries

from Pylontech. This allows surplus PV to

accumulate energy and be used later, for example, for

peak shaving or off-grid. Pylontech batteries are

shown in Figure 5.(CEET Website, 2025)

Figure 5: Pylontech Batteries.

3 HYDROGEN

INFRASTRUCTURE

The hydrogen technology laboratory is equipped with

technological equipment for the electrolytic

production of hydrogen and equipment for its reverse

conversion into electricity using fuel cells. Fuel cells

produce DC electricity and heat by directly

converting hydrogen fuel and oxidant to electrical

energy in a catalytic process that uses a non-explosive

and non-flammable fusion reaction. Pure hydrogen

gas with defined purity and parameters is used as the

Centre for Energy and Environmental Technologies – Explorer (CEETe): Advanced Scientific Perspectives and Applications

217

fuel, and air is used as the oxidant. The fuel cell

modules or fuel cell 'stacks' shall use chemical and

physical processes consistent with polymer proton

exchange membrane technology, and the individual

fuel cell 'stacks' shall be designed for this technology.

According to established international

nomenclature, the laboratory has installed low-

temperature fuel cell modules classified as Proton

Exchange Membrane Fuel Cells, commonly called

PEM or PEMFC fuel cells. The laboratory is

designing the distribution and metering systems for

industrial gases to enable the connection of fuel cells

with an installed power of approximately 100 kWe.

The envisaged installation, serving the research

purposes of CEETe, consists of 5 modules ("stacks")

in a primarily series electrical connection, with a total

installed output power of 50 kW, used to generate

electricity (and heat) from the supplied hydrogen gas

with defined parameters. (CEET Website, 2025)

The electrical power is connected via a coupling

power converter in the hydrogen laboratory control

room to an AC bus at a 3 x 230/400 V for other

CEETe process units. The heat produced (up to 80

CEET Web (2025)kWt) is mainly dissipated through

a water-cooling circuit with demineralised water,

with a temperature gradient of 65/60 °C, which will

be divided into two parts by a heat exchanger, with

the secondary part already being part of the waste heat

recovery system for building purposes. As a matter of

interest, we have added

Figure 6

which shows the

hydrogen laboratory's digital design, and Figure 7

shows an actual photo of the hydrogen

laboratory.(CEET Website, 2025).

Figure 6: Digital Model of Hydrogen Laboratory.

The input media for the fuel cells will be:

humidified reaction air (up to 5 ∙ 500 N∙l∙

-1

),

supplied from the reaction air supply system

by blowers (compressors),

hydrogen gas (up to 5 ∙ 200 N∙l∙min

-1

) stored

in the outdoor hydrogen filling station.

The inerting of the fuel cells will be carried out using

nitrogen gas.

Figure 7: Hydrogen Laboratory.

The electrolysers produce hydrogen gas with

defined parameters and quality per the specifications

below. They are principally based on water

electrolysis or a suitable aqueous electrolytic solution

utilising solid ion polymer membrane technology.

Furthermore, industrial gas distribution and metering

systems in the laboratory are designed to connect two

types of electrolysers with an installed max power of

85 kWe.(CEET Website, 2025)

The AEM-type electrolysers are installed in

several freestanding modular carts. The hydrogen gas

produced will be extracted from the individual

production units via separate pressure hoses

containing the required number of hydrogen

production equivalents, i.e., 4 N∙m

3

∙block

-1

. The

operating hydrogen production by these electrolysers

is assumed to be at least 1 N∙m

3

∙h

-1

(max. 8 N∙m

3

∙h

-1

)

at a pressure of 30 bar, with a system of treating the

physical parameters of hydrogen—separation of

residual moisture—incorporated into the pipeline

route of the produced hydrogen. The medium

(electrolyte) for hydrogen production is a

demineralised water solution with 1% K2CO3+

KHCO3. (CEET Website, 2025)

The electrolyte circuit, which serves the purpose

of both cooling and supplying reaction water, will be

automatically replenished during the operation of the

AEM electrolysers in the amount of 4 l∙h

-1

for each

production unit, i.e., up to 8 l∙h

-1

in total. The

electrolyte circuit removes heat from the electrolyser

units with a value of 12 kWt while maintaining a

temperature gradient of 45/40 °C. In the supply

branch of this circuit, primarily located one floor

above (the room of the air handling plant), the heat

exchanger will be connected to the central cooling

water source of CEETe. The return line (from the

electrolyser outlet), containing not only the

electrolyte but also the gaseous oxygen produced by

electrolysis in a quantity of at least 2 Nm

3

∙h

-1

(max. 4

SMEN 2025 - Special Session on Smart City and Smart Energy Networks

218

N∙m

3

∙h

-1

), will be discharged into a non-pressurised

expansion tank from which the accumulated oxygen

and the water mist produced in the tank will be

actively vented outside the building by a fan. The

vessel will also incorporate electrical heating for the

start-up phase of the electrolysers. Their inerting will

be carried out with nitrogen gas. As a matter of

interest, we have added Figure 8, which shows the

outdoor hydrogen filling station during refuelling for

the hydrogen vehicle.(CEET Website, 2025)

Figure 8: Hydrogen Refuelling for the Vehicle.

4 THE THERMOCHEMICAL

CONVERSION LABORATORY

The Thermochemical Conversion Laboratory focuses

on research into advanced technologies for the

thermo-chemical conversion of waste materials, with

plasma gasification being a key activity area. This

innovative technology is a highly efficient and

environmentally friendly method of converting waste

into energy-using products, overcoming the limits of

traditional incineration and standard gasification

processes. The extremely high temperatures of up to

2000 °C in the plasmatron result in near-perfect

decomposition of the feedstock and minimise

unwanted emissions or solid residues.

The entire plasma gasification process consists of

several stages. The first step is the pre-treatment and

dosing of the raw materials, which are then fed into

the plasma reactor, where they are gassed under

intense thermal radiation. The resulting synthesis gas

(syngas) is then subjected to a multi-stage purification

process, where unwanted components are removed,

and the individual fractions are separated. This

treated gas can then be used in various energy

applications, for example, for the production of

synthetic hydrocarbon fuels, for the cogeneration of

electricity and heat, or for the production of

hydrogen, which, after separation and purification,

can be used in fuel cells.

The laboratory is equipped with a state-of-the-art

150 kW plasmatron, part of a complex technological

system including a superheated steam generator,

cooling circuit, raw material transport system,

oxidation medium supply and waste management.

Synthesis gas purification is carried out in several

stages using high-temperature filtration, wet and

alkaline scrubbing and advanced membrane

separation, which allows selective extraction of key

gases, including hydrogen.

One of the main advantages of plasma gasification

is that it is environmentally friendly, as the process

generates minimal harmful emissions and allows

efficient use of the energy potential of the waste.

Dioxins and nitrogen oxide emissions are

significantly reduced compared to conventional

incineration technologies. At the same time, residual

inorganic components are converted into inert glassy

slag that can be further used, for example, in the

construction industry. Another advantage is the high

flexibility of the process, which allows the treatment

of a wide range of materials, including biomass,

plastics, industrial waste and hazardous substances.

The laboratory currently focuses on optimising

the hydrogen separation process for its subsequent

use in fuel cells and the efficient production of

synthetic hydrocarbon fuels. An important research

direction is linking plasma gasification technology

with hydrogen management and its potential

integration into decentralised energy systems.

The thermochemical conversion laboratory is thus

creating a unique platform for developing and testing

advanced technologies for converting waste into

clean energy products, hence contributing to the

development of the circular economy and sustainable

energy solutions. The research results have potential

for industrial applications and wide deployment in

municipal and local energy systems, which can

contribute significantly to minimising negative

environmental impacts and increasing energy self-

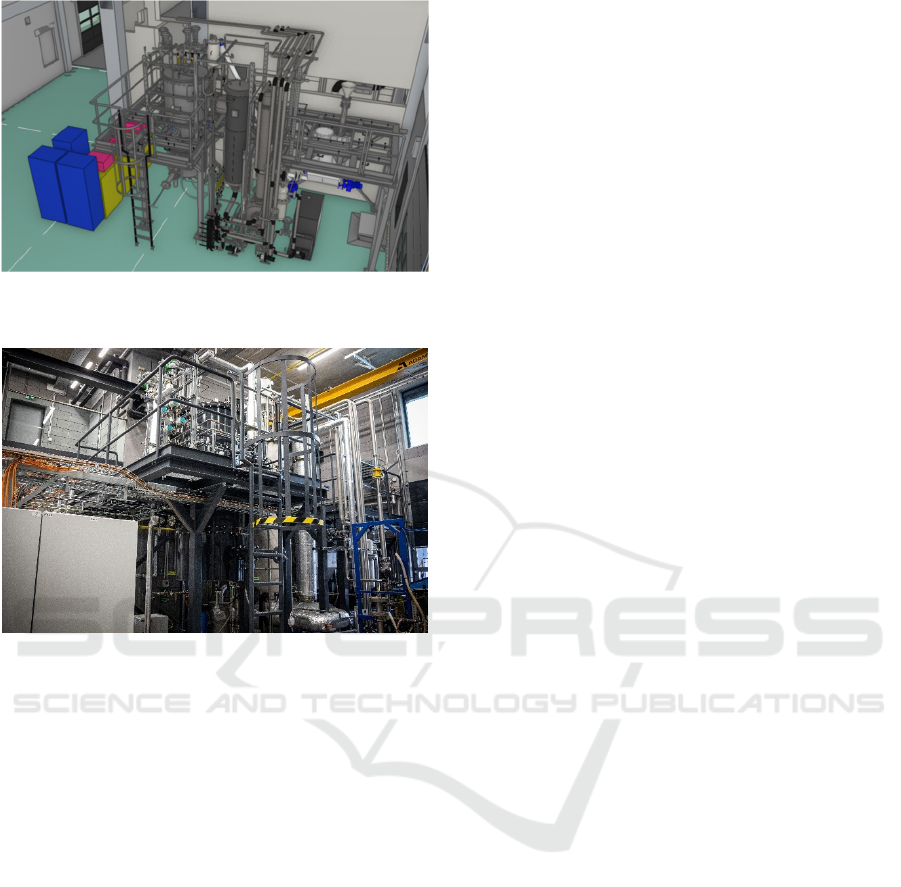

sufficiency. As a matter of interest, we have added

Figure 9, which shows the digital model of the

thermochemical conversion laboratory digital design,

and Figure 10, which shows an actual photo of the

thermochemical conversion laboratory.

The thermochemical conversion laboratory is thus

creating a platform for developing and testing

advanced technologies for converting waste into clean

energy products, contributing to the development of

the circular economy and sustainable energy solutions.

The results have the potential for industrial

applications and wider deployment in municipal and

local regional energy systems, which can significantly

minimise negative environmental impacts and increase

energy self-sufficiency.(CEET Website, 2025)

Centre for Energy and Environmental Technologies – Explorer (CEETe): Advanced Scientific Perspectives and Applications

219

Figure 9: Digital Model of Thermochemical Conversion

Laboratory.

Figure 10: Thermochemical Conversion Laboratory.

5 CONCLUSIONS

CEETe is a key element of modern research and

development in sustainable energy and environmental

technologies. Its interdisciplinary approach enables the

efficient integration of renewable resources, the

development of hydrogen technologies, the

optimisation of microgrid management, and the

implementation of circular economic models.

Advanced digital simulation and the digital twin

concept have created a unique platform that allows

experimental validation, predictive control, and

optimisation of energy flows in real-time.

The results obtained so far confirm the high

potential of decentralised energy communities and

the importance of efficient management of distributed

energy systems. The combination of photovoltaics,

battery storage, hydrogen infrastructure and

intelligent control algorithms allows for achieving

higher energy self-sufficiency, optimising

consumption and reducing operating costs. Thus,

CEETe becomes a reference model for applying

advanced technologies in academic settings,

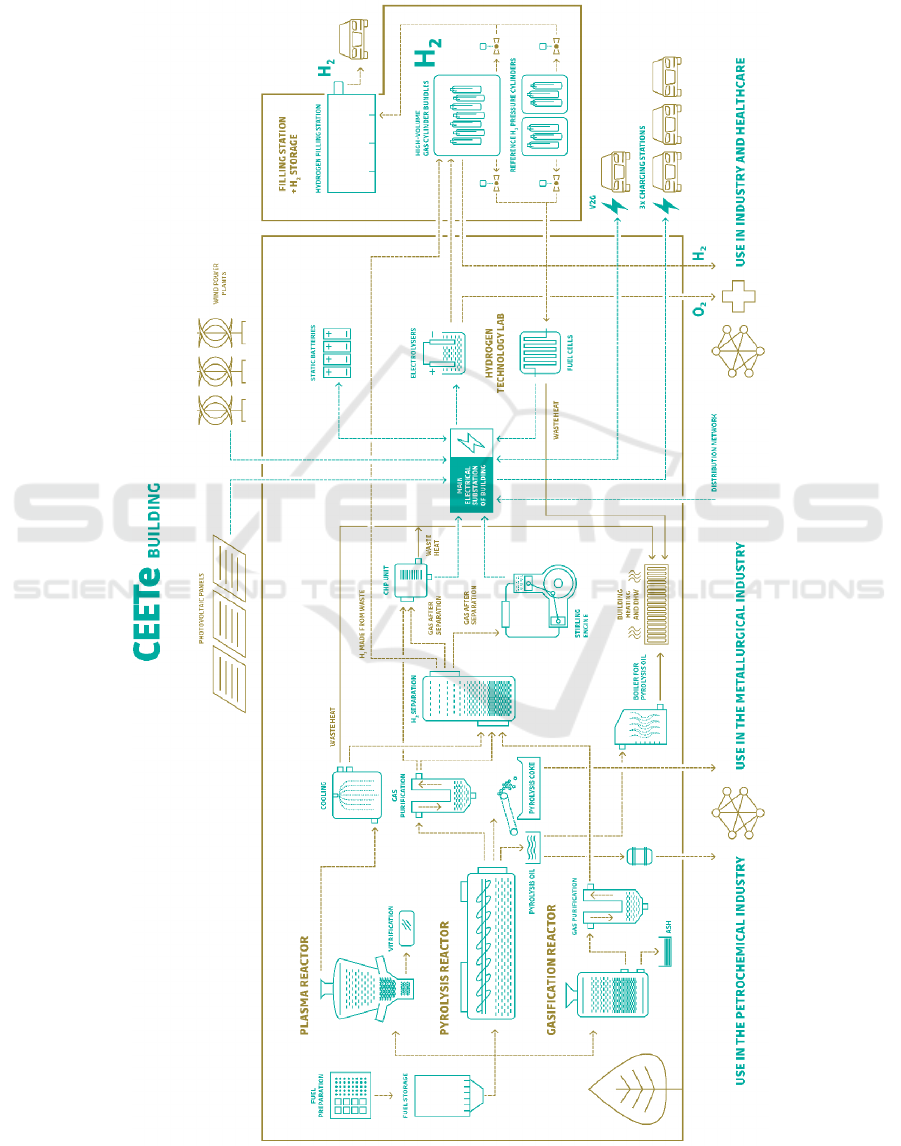

industrial practice, and urban energy systems. A full

schematic of the CEETe technology is attached for

completeness. Not everything could be described in

the article. The article would be substantially

extensive. The article serves as a basic description of

the technology platform.

In the future, the CEETe testbed is envisaged to

be extended with new features, including developing

decentralized energy communities, advanced peer-to-

peer energy transaction management, and blockchain

technologies to ensure transparency and security of

energy trading. Future directions of the project will

include deeper integration of renewable energy

sources into the university infrastructure to create a

smart and adaptive energy system for the VSB-TUO

campus that will serve as a model for future

decentralized energy systems.

The results achieved within the CEETe research

platform thus represent a significant contribution to

innovation in sustainable energy and environmental

management. Their application will enable more

efficient use of energy resources, carbon footprint

reduction, and energy independence development

within the European context.

ACKNOWLEDGEMENTS

This article has been produced with the financial

support of the European Union under the REFRESH –

Research Excellence For REgion Sustainability and

High-tech Industries project number CZ.10.03.01/

00/22\_003/0000048 via the Operational Programme

Just Transition. The LTI20004 Environmental

Research and Development Information Centre also

supported the article. This article was also supported

by the Technology Agency of the Czech Republic

under the project "ESO – Vehicle of Category N1

Powered by Hydrogen Cells," project number CK04

000248. The photos in the article were taken by the co-

author of the article Vojtech Blazek. In this article,

Grammarly software was used to check grammar.

REFERENCES

Blažek, V. (2024). Optimalizace ve SMART GRID [Vysoká

škola báňská – Technická univerzita Ostrava].

Retrieved from http://hdl.handle.net/10084/152741

CEET Website. (n.d.). Https://Ceet.vsb.Cz/En. Retrieved

from https://ceet.vsb.cz/cs

Misak Stanislav, & Prokop Lukas. (2024, June). Centre For

Energy And Environmental Technologies: Portfolio.

Https://Ceet.vsb.Cz/Export/Sites/Ceet/.Content/Galeri

e-Souboru/CEET-Portfolio-EN_revize.Pdf.

SMEN 2025 - Special Session on Smart City and Smart Energy Networks

220

APPENDIX

The technical diagram of the CEETe research platform is attached on the next page. The diagram describes the

interaction of the different technologies. (Blažek, 2024).

Centre for Energy and Environmental Technologies – Explorer (CEETe): Advanced Scientific Perspectives and Applications

221